Heat radiating device

A heat dissipation device and heat sink technology, applied in cooling/ventilation/heating transformation, electrical equipment construction parts, instruments, etc., can solve the influence of the direction and position of the air outlet 521, and cannot flexibly adjust the direction and position of the airflow at the air outlet 521 , It is difficult to meet the problems of the shape design of the casing, so as to achieve the effect of convenient shape design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

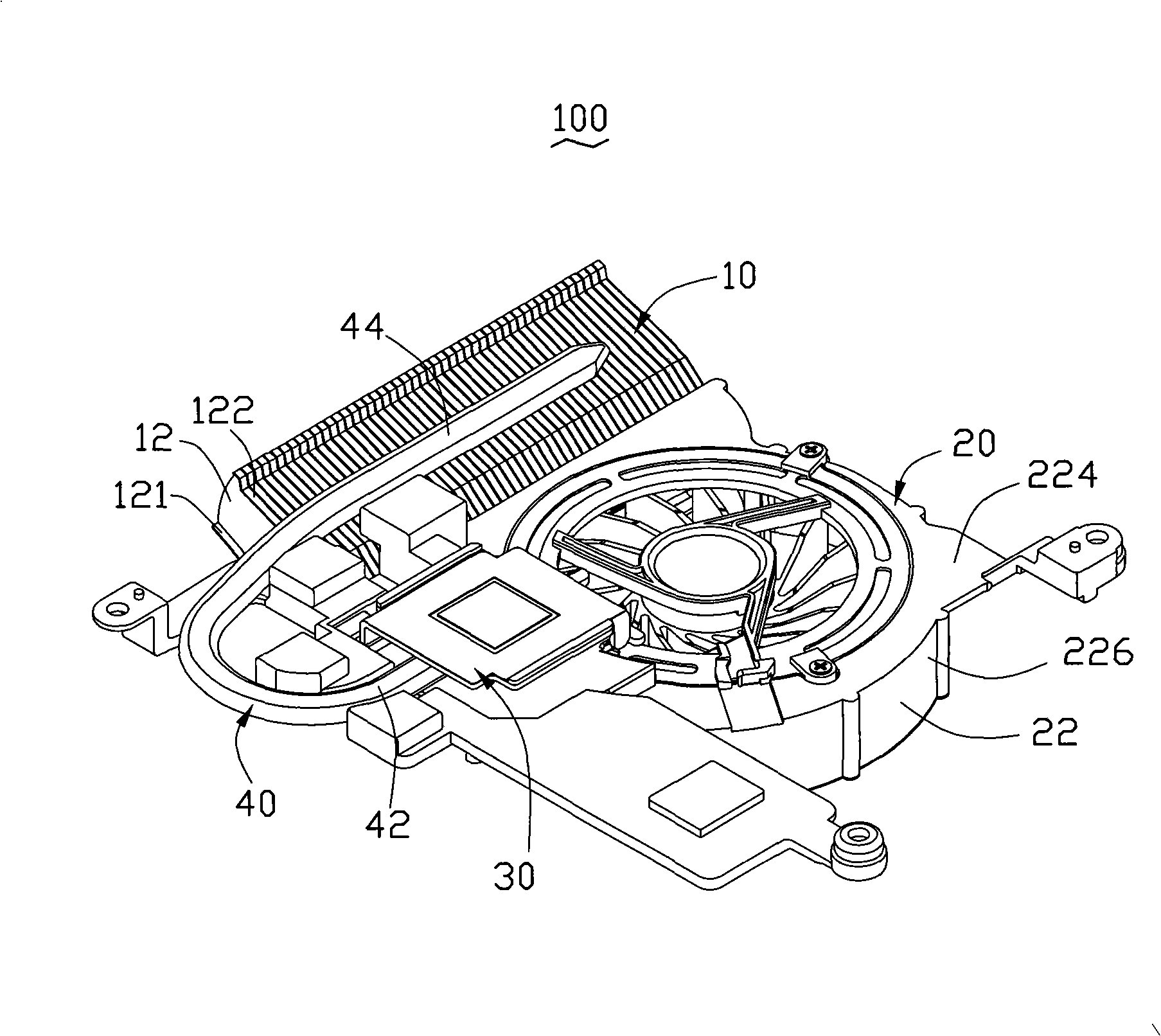

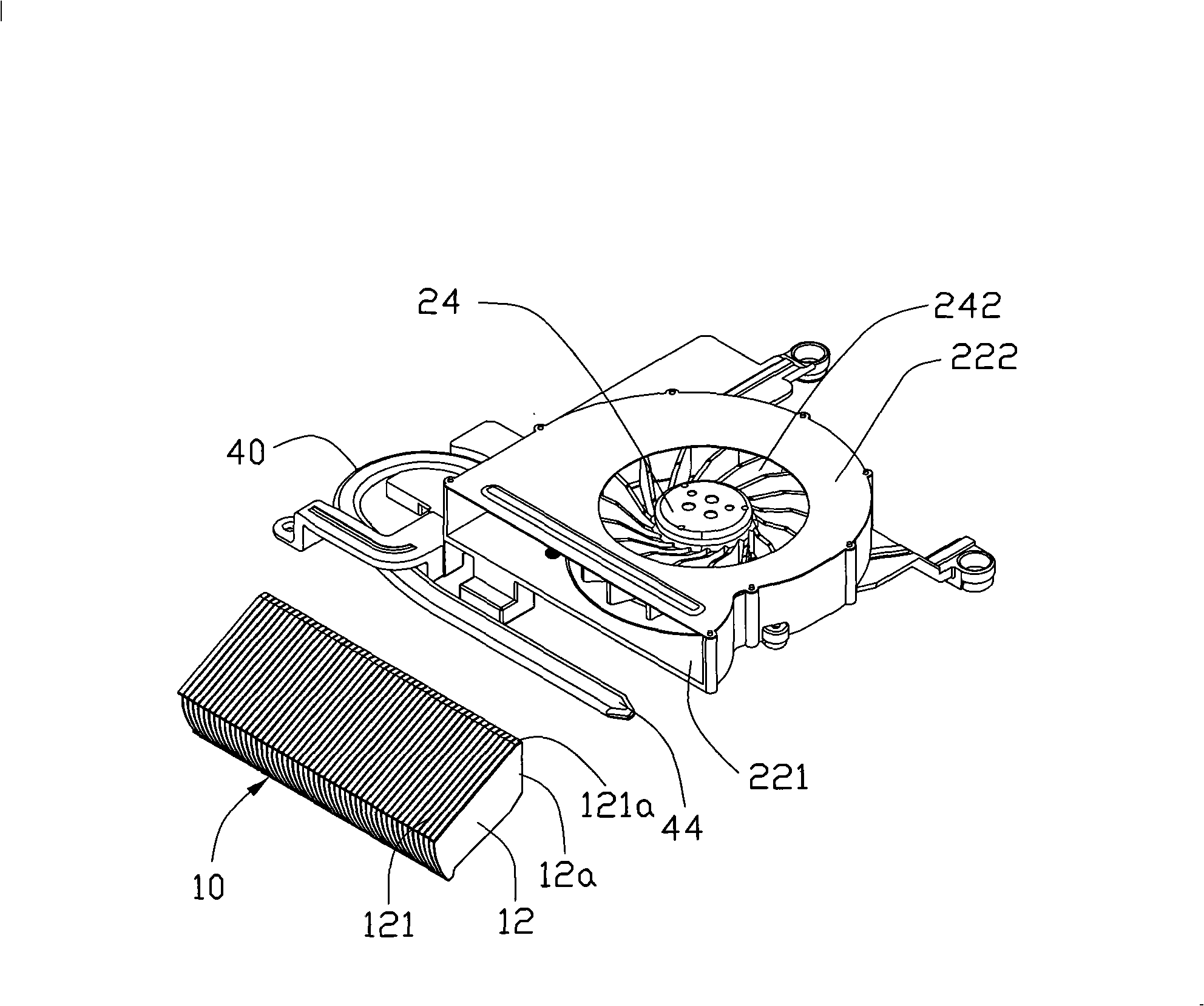

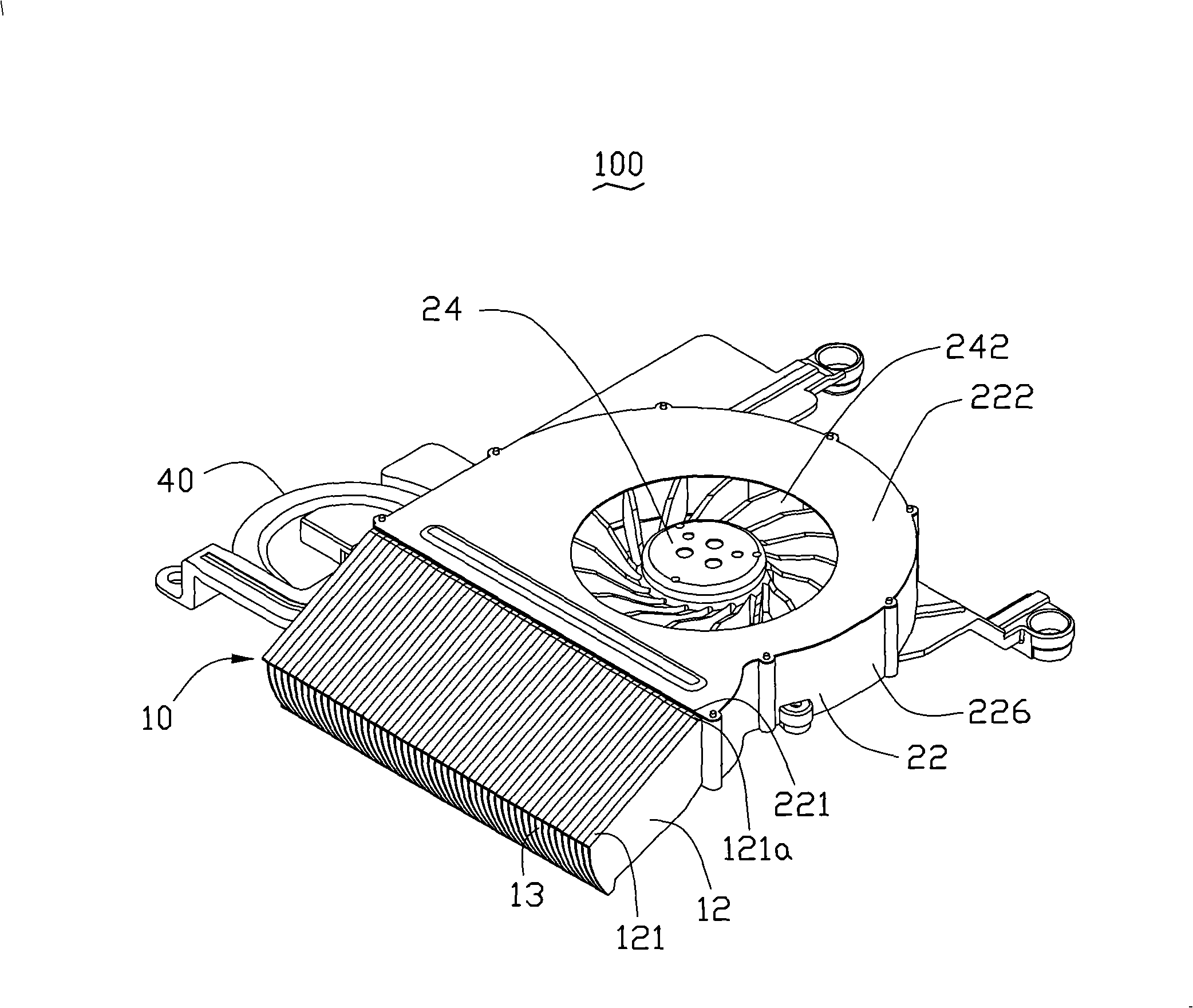

[0016] figure 1 Shown is a three-dimensional assembly view of the first embodiment of the heat dissipation device of the present invention along a first viewing angle. The heat dissipation device 100 can be installed in the casing (not shown) of electronic products such as notebook computers or all-in-one liquid crystal computers (LCD PCs). , which includes a radiator 10 , a centrifugal fan 20 , a base 30 and a heat pipe 40 . The base 30 is thermally connected to a heat-generating electronic component (not shown) located in the casing, one end of the heat pipe 40 is thermally connected to the base 30, and the other end is attached to the heat sink 10, and the base The heat on the seat 30 is transferred to the heat sink 10 . The centrifugal fan 20 is used to forcibly dissipate heat from the radiator 10 .

[0017] Please refer to Figure 1 to Figure 3 , the centrifugal fan 20 includes a casing 22 , a stator (not shown) and a rotor 24 , the stator and the rotor 24 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com