Quick changing bending machining pad pillow

A technology of bending and cushioning, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large changeover time and labor costs, and achieve the effect of reducing capital equipment costs and reducing changeover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

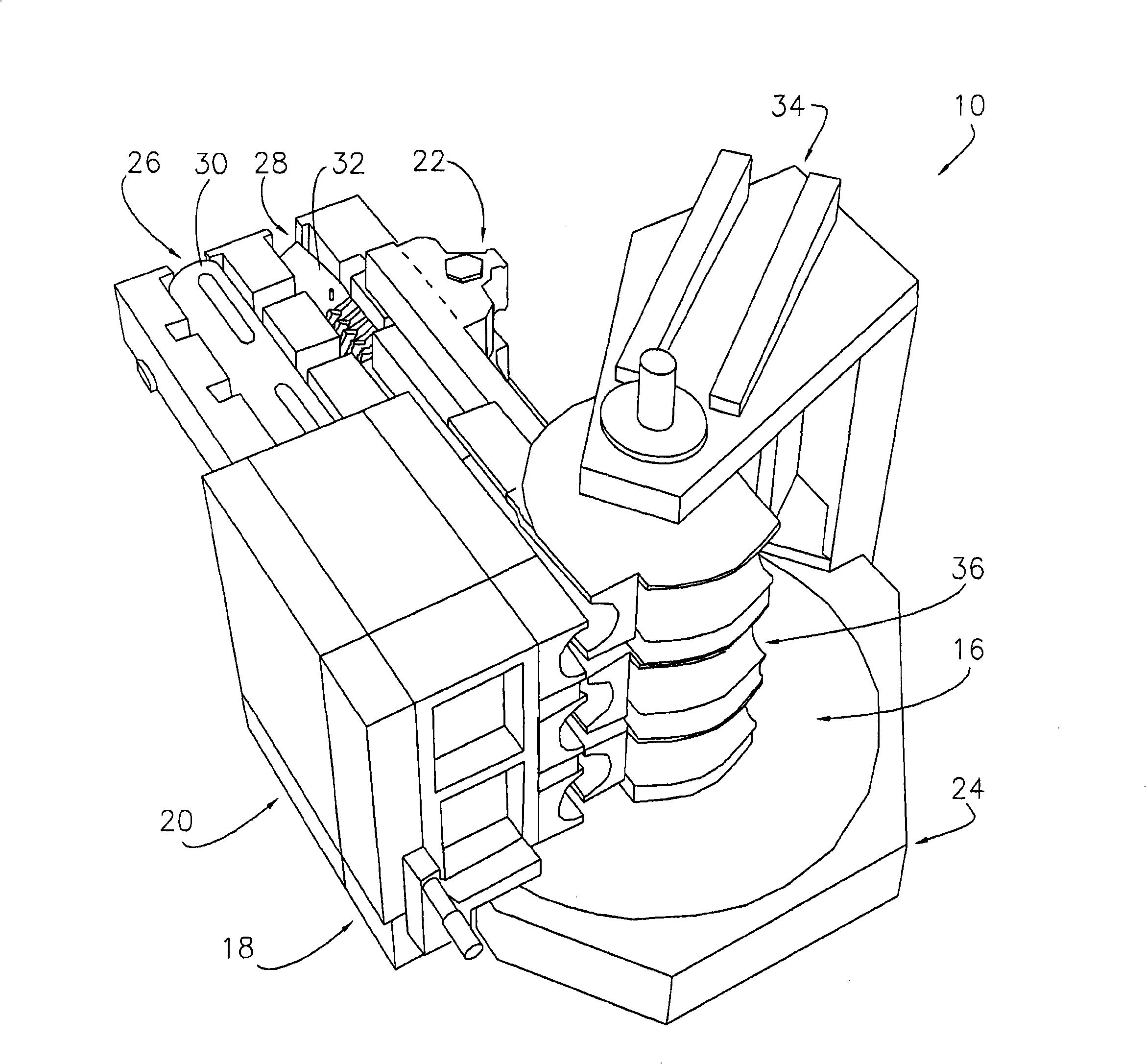

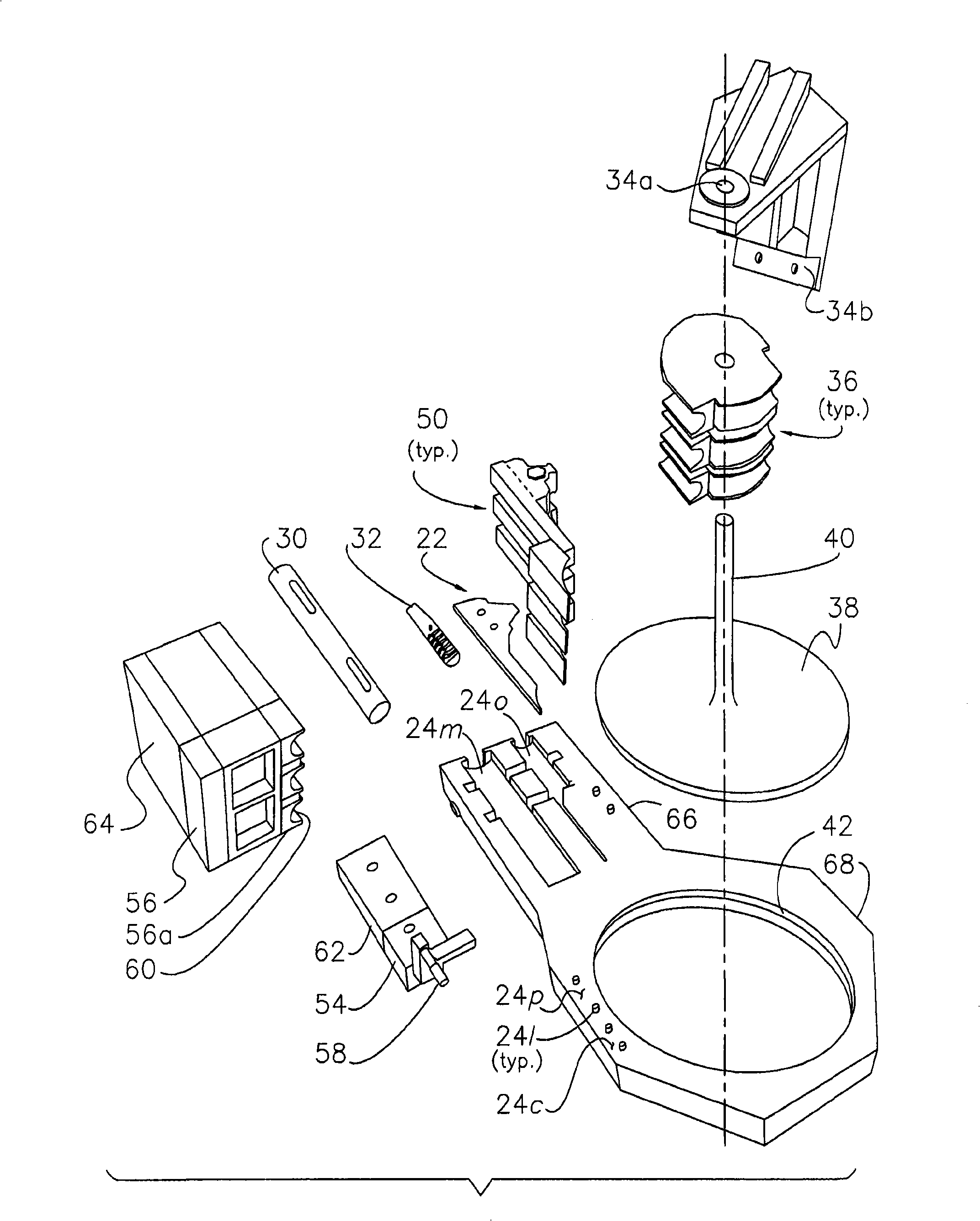

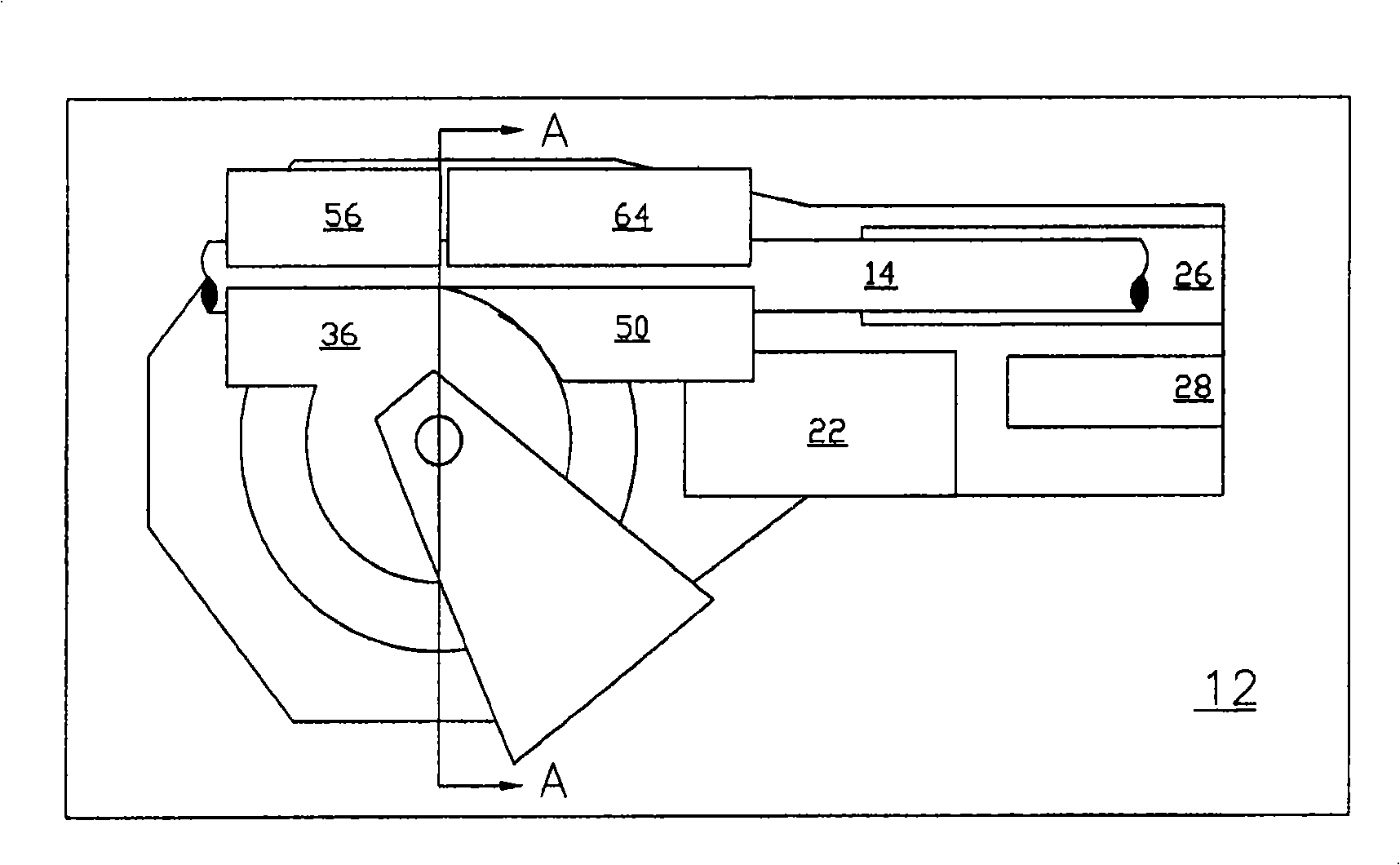

[0011] Such as Figure 1-12 As shown, the present invention relates to a novel bender assembly 10, 100 adapted to be used with a rotary drawing bender or bender 12 ( image 3 ), the rotary stretch pipe bender or bender 12 is, for example, a computer numerically controlled (CNC) bender, a numerically controlled (NC) bender, or a conventional type bender. As is known in the art, the function of the rotary stretch bender 12 is to compress the tube 14 against the bend profile such that the point at which the bend occurs is fixed and the profile is tangent to the entry line of the tube 14 (cf. image 3 with 3a and Figure 10 with 10a ). Typically, to achieve this, bender 12 rotates the bending dies and uses a series of other dies to hold or grip the tube and exert pressure on the tube. Bending machine 12 may use manual, machine-assisted manual, electric, hydraulic, or electro-hydraulic systems to achieve rotational displacement. While the preferred assembly 10, 100 is describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com