Ratchet wrench

A wrench and pawl technology, applied in the field of open ratchet wrench, can solve the problems such as difficult to use ratchet wrench, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

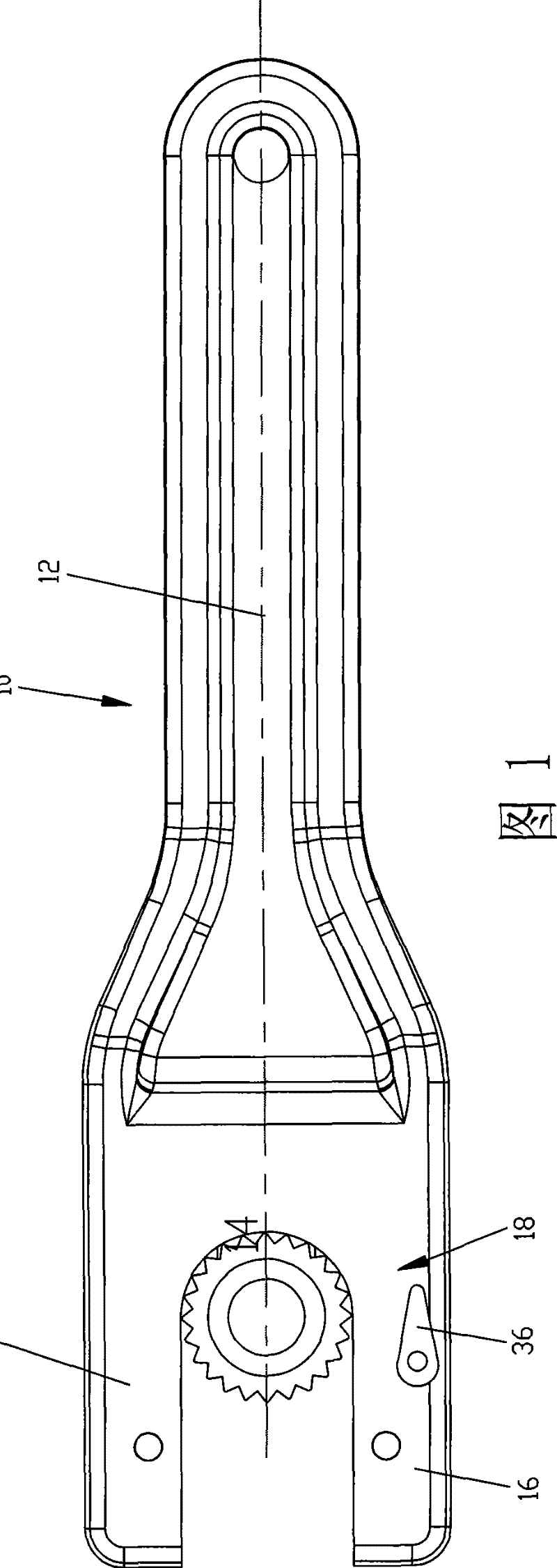

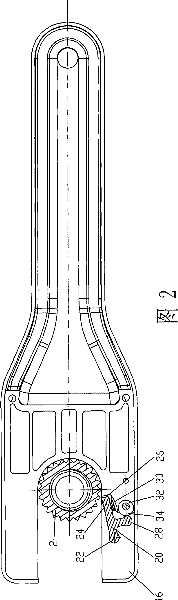

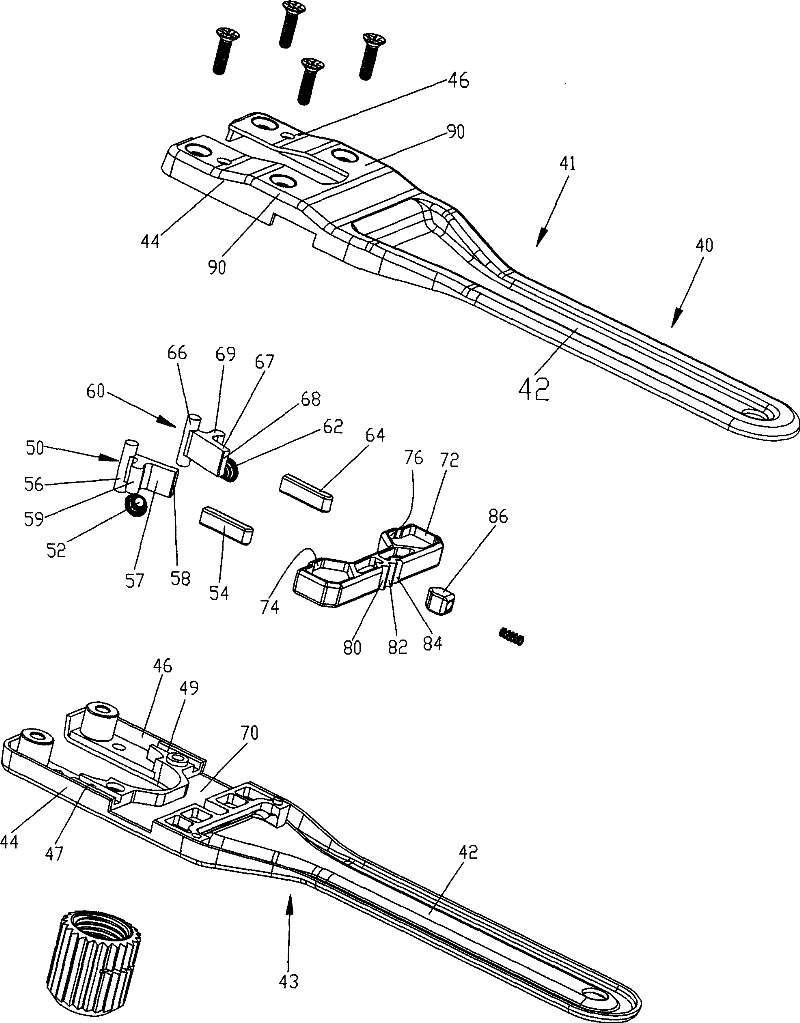

[0019] refer to figure 1 and figure 2 As shown, the wrench 10 according to the first preferred embodiment of the present invention includes a handle portion 12 extending longitudinally and a jaw portion 18 composed of two separate jaws 14, 16, wherein the first jaw 16 is near the jaw. One end is provided with the pawl 20 and the elastic element 30 and the conversion piece 32 that are matched with the pawl 20 . The cross-section of the ratchet 20 is roughly T-shaped, and one end 22 of the transverse section of the T-shaped ratchet 20 close to the jaw is pivotally connected to the jaw 16, and the other end 24 leans against the elastic element 30 and is provided with a workpiece occlusal surface 26 , The vertical section 28 of the T-shaped pawl 20 is matched with the conversion piece 32 . The conversion member 32 is pivotally connected to the claw 16, and one end matched with the vertical section 28 of the ratchet 20 is provided as a cam surface 34, and the other end is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com