Plate valve for tensioining systems for traction means

A tensioning system and tool technology, applied in the direction of valve devices, control valves, function valve types, etc., can solve the problems affecting the installation space of the hydraulic valve of the tensioning device, large structural space, etc., to achieve reduced quality, large pressure action area, The effect of optimal working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

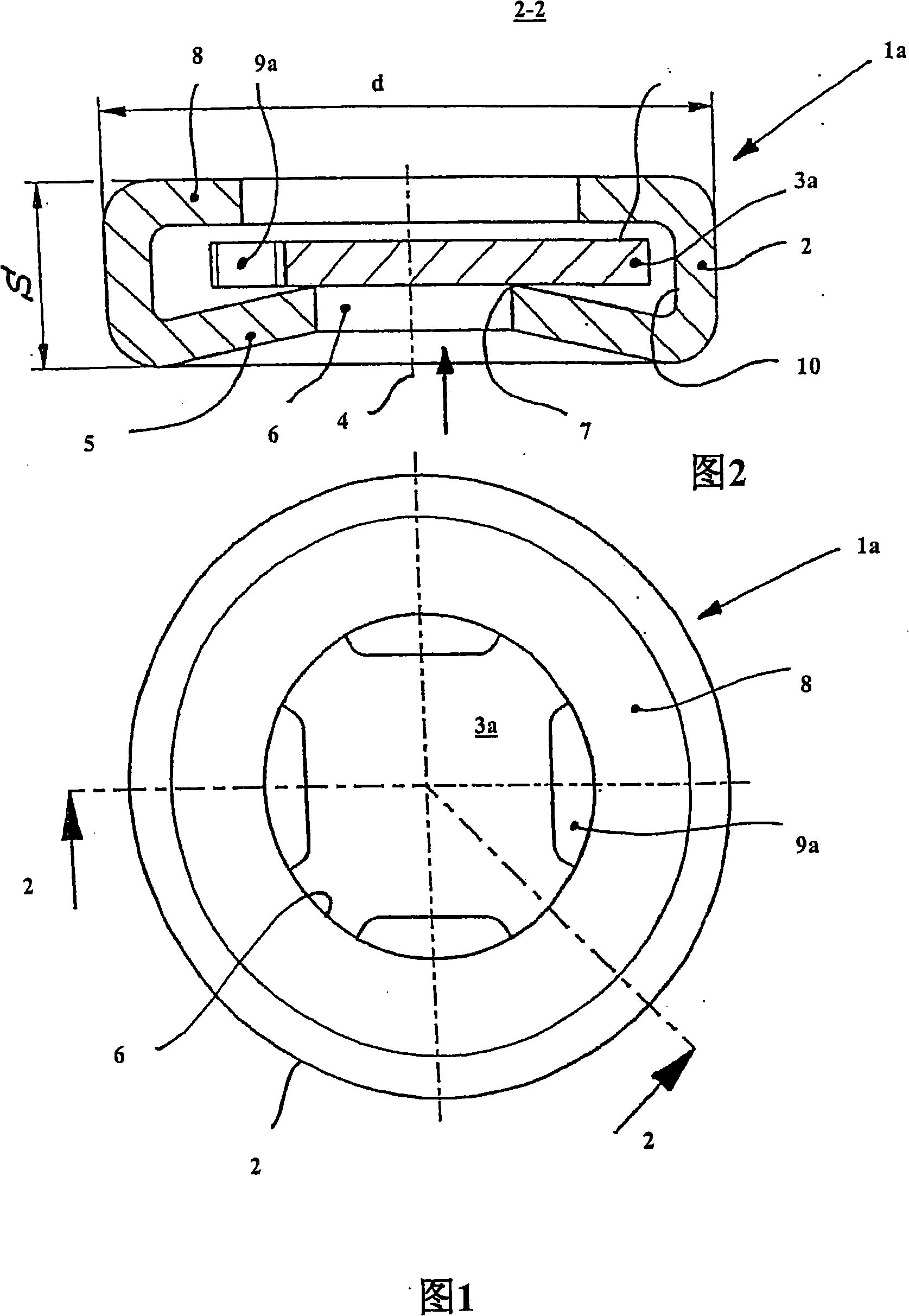

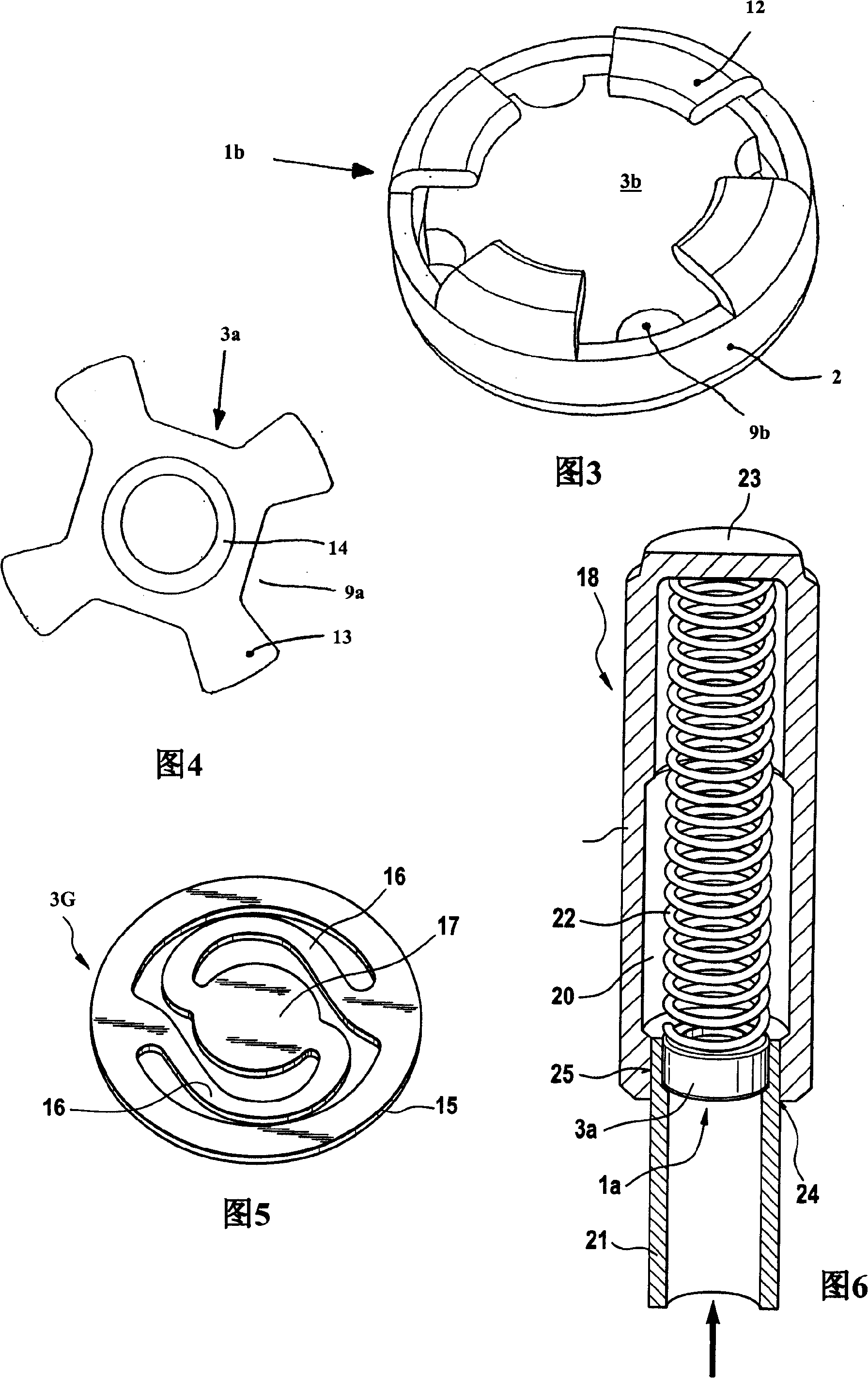

[0024] 1 and 2 show a rotationally symmetrical non-return valve 1a designed as a plate valve. This structure comprises a housing formed as a cage 2 into which a valve body 3a formed as a disk is inserted with play. The cage 2 produced without cutting comprises a base 5 that tapers conically towards the longitudinal axis 4 . An opening 6 is formed in the center of the bottom 5 , on the inner side of which the valve body 3 a is supported in a sealing manner on the edge region forming the valve seat 7 . The cage 2 is distanced from the bottom 5 by a continuous rim 8 with a right-angle chamfer, which prevents loss of the valve body 3a and at the same time limits the lift. FIG. 2 shows the non-return valve 1 a in the closed position, in which the valve body 3 a rests tightly against the valve seat 7 . When the check valve 1a is loaded with hydraulic fluid in the direction of the arrow, the valve body 3a moves to the inner side of the rim 8 . In this respect, hydraulic fluid can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com