Pattern checking device and pattern checking mehtod

A technology for inspection devices and inspection methods, which is applied in the direction of measuring devices, instruments, measuring electronics, etc., and can solve the problems of being unable to detect whether there are pits or not

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiments of the present invention will be described using FIGS. 1 to 10 .

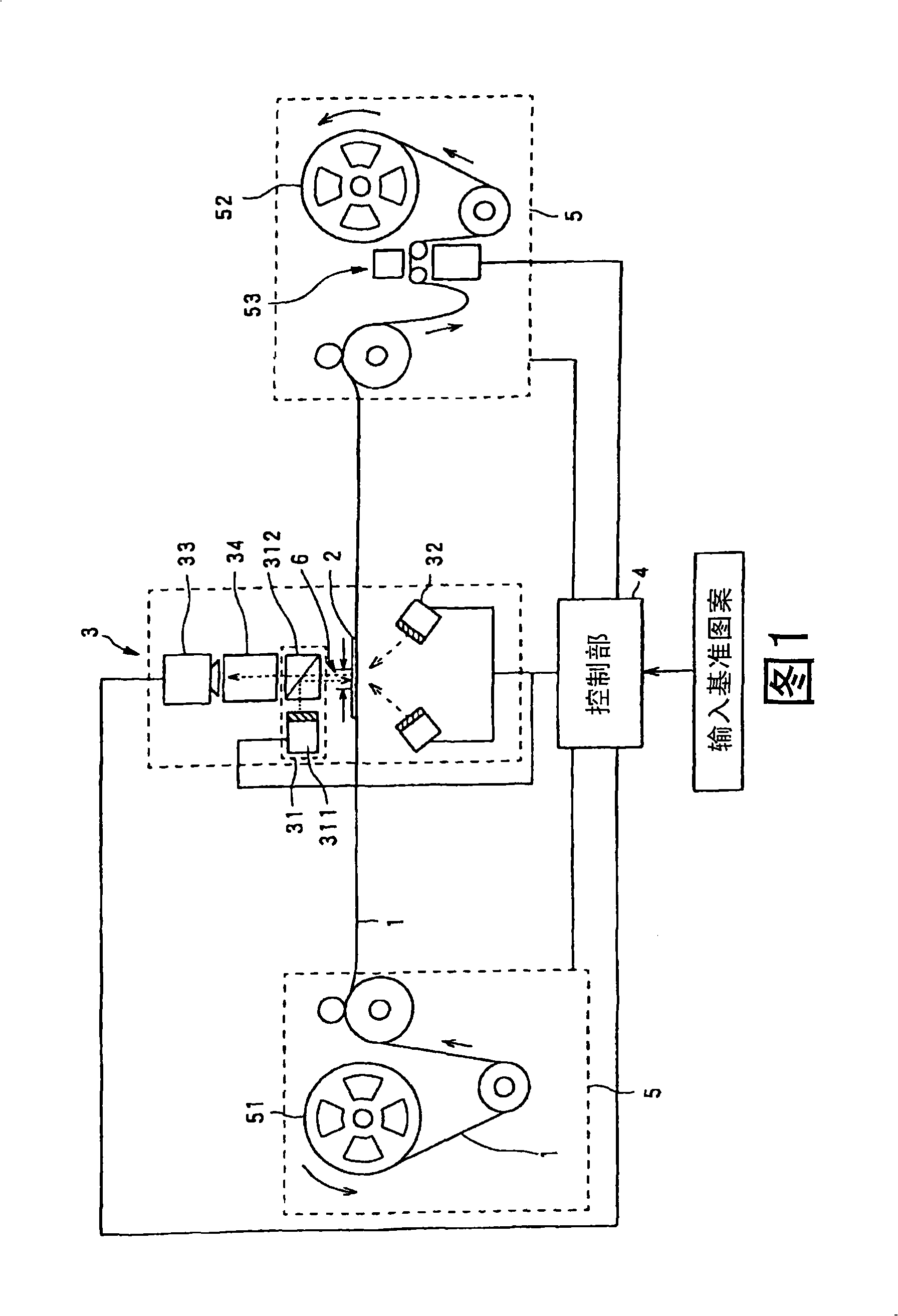

[0061] FIG. 1 is a block diagram showing the overall configuration of a pattern inspection device according to the invention of the present embodiment.

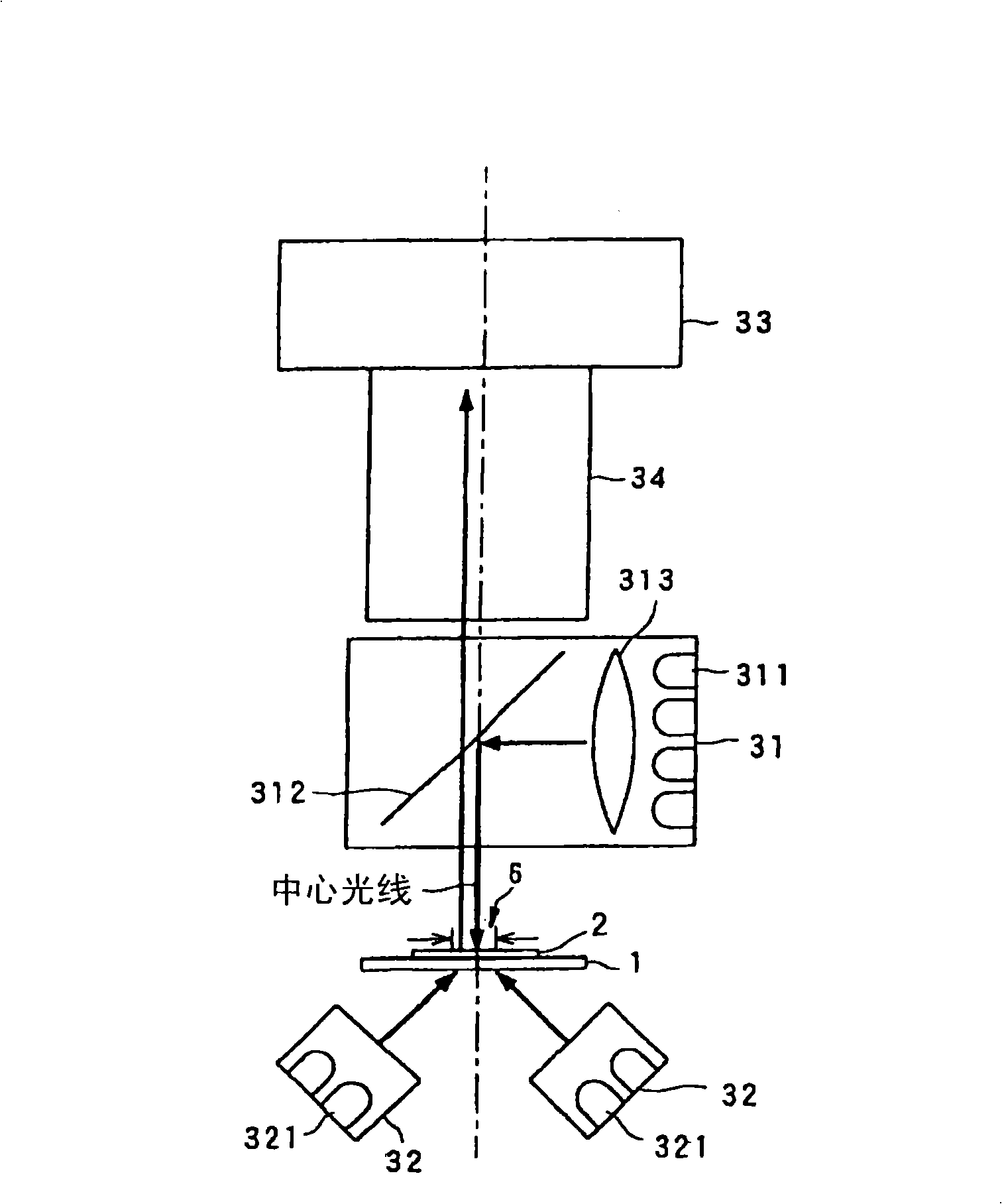

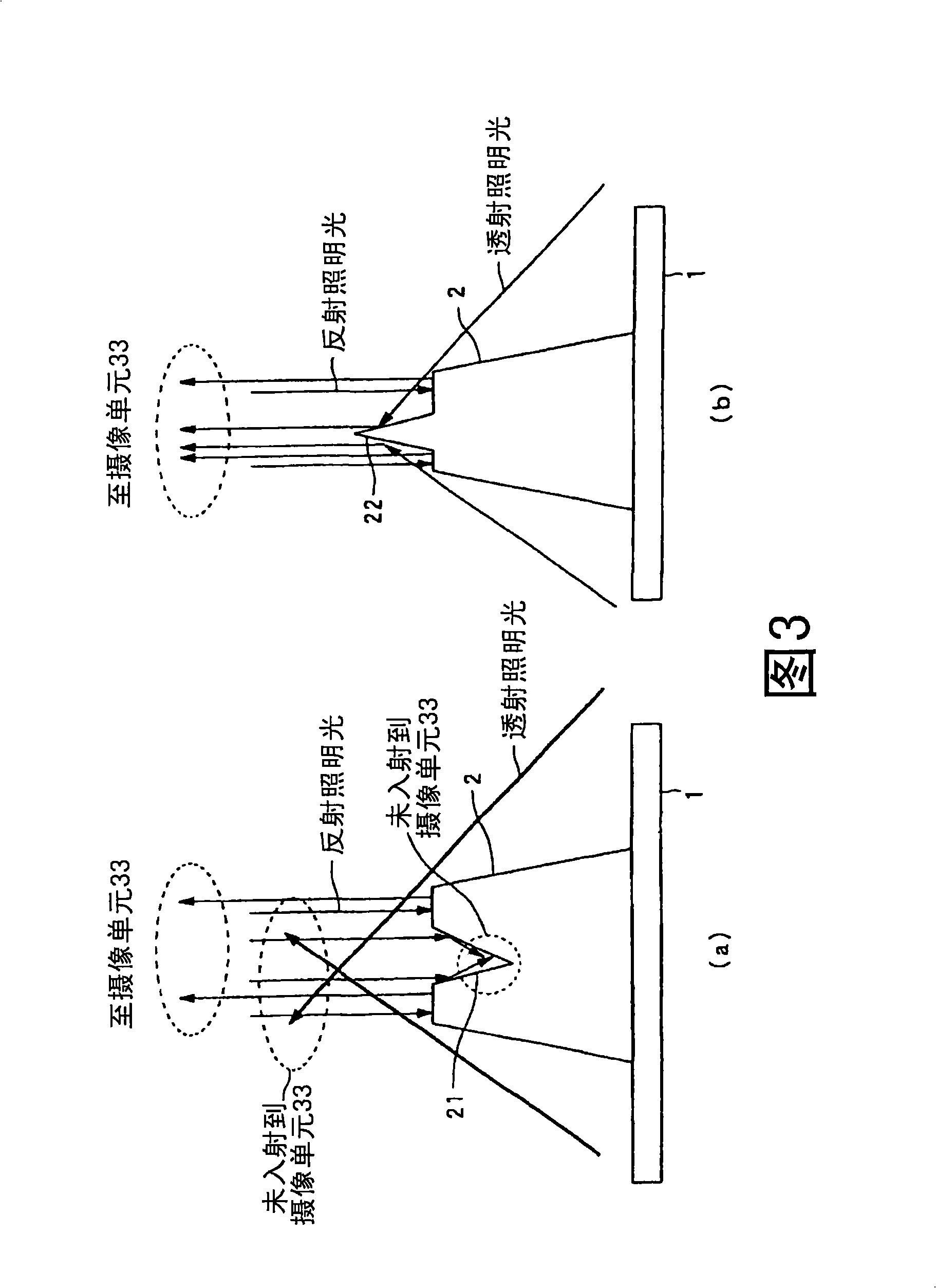

[0062] In FIG. 1, 1 is a light-transmissive substrate such as a TAB tape made of polyimide (resin), etc., 2 is a pattern such as a wiring pattern formed on the substrate 1 and made of copper, etc., 3 is an inspection part, and 31 It is a reflected illumination unit (first illumination unit) that irradiates illumination light passing through the center of the beam center of the illumination light from the side on which the pattern 2 on the substrate 1 is substantially perpendicular to the inspection area of the substrate 1 (first illumination unit), 311 is a light source, 312 is a half mirror, and 32 is on the opposite side to the side where the pattern 2 on the substrate 1 is formed, from the area illuminated by the first lighting unit on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com