Lens module group assembling system and method of use thereof

A technology for assembling systems and lens modules, applied in installation, optics, instruments, etc., can solve problems such as difficult lens barrels, difficult assembly, and large manpower consumption, and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

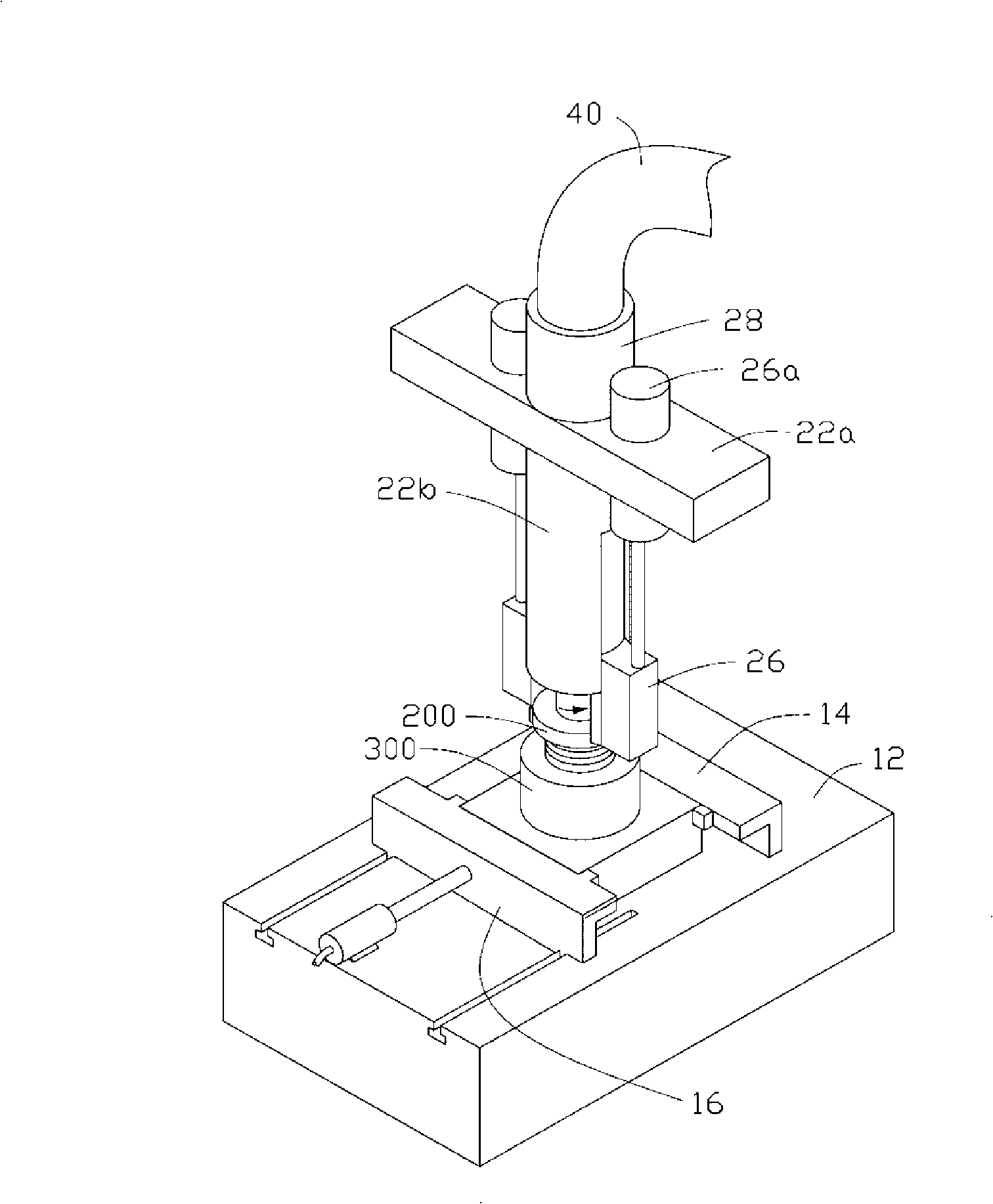

[0011] The lens module assembly system provided by the present invention and its usage method will be described in further detail below in conjunction with the accompanying drawings.

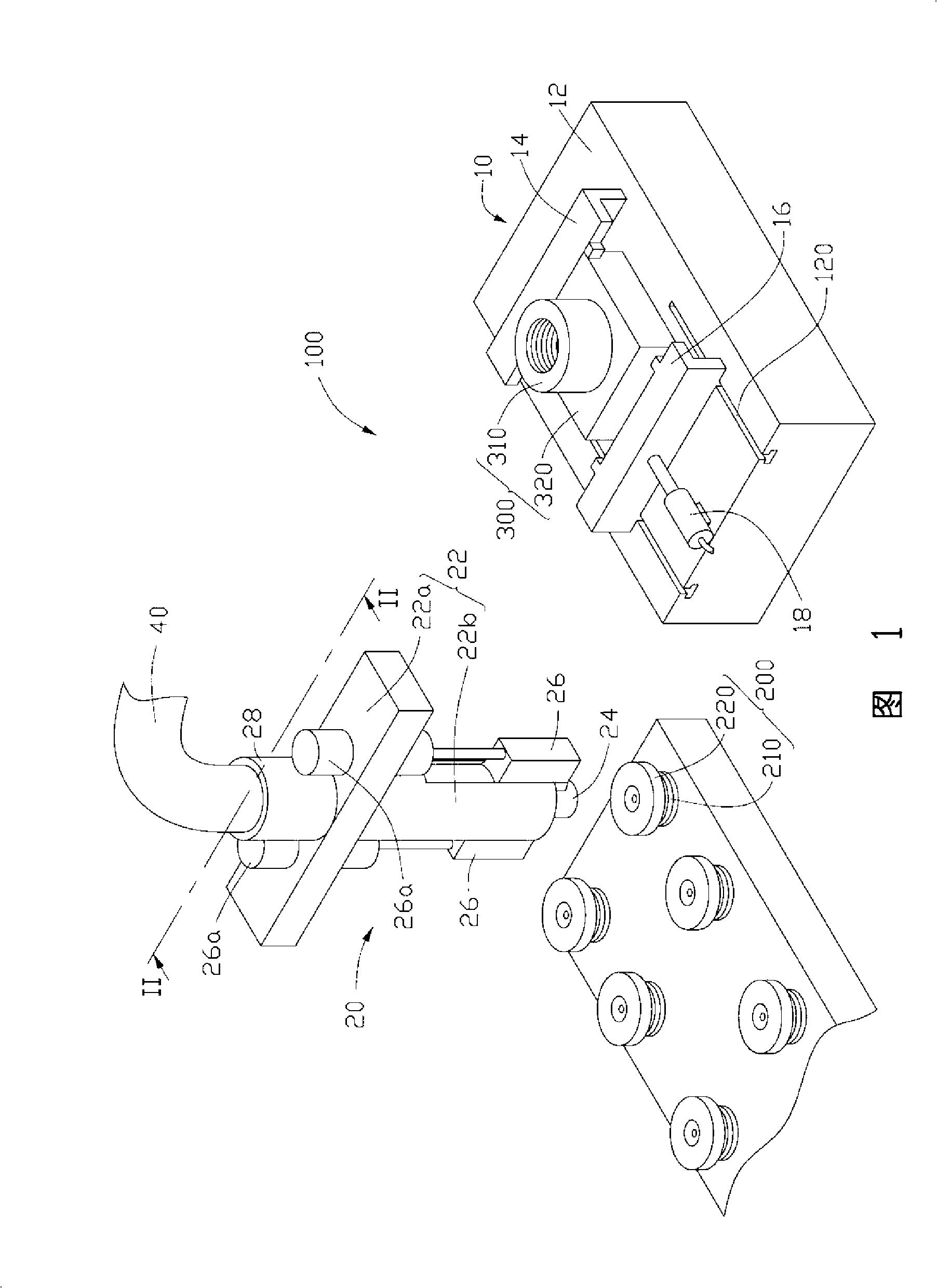

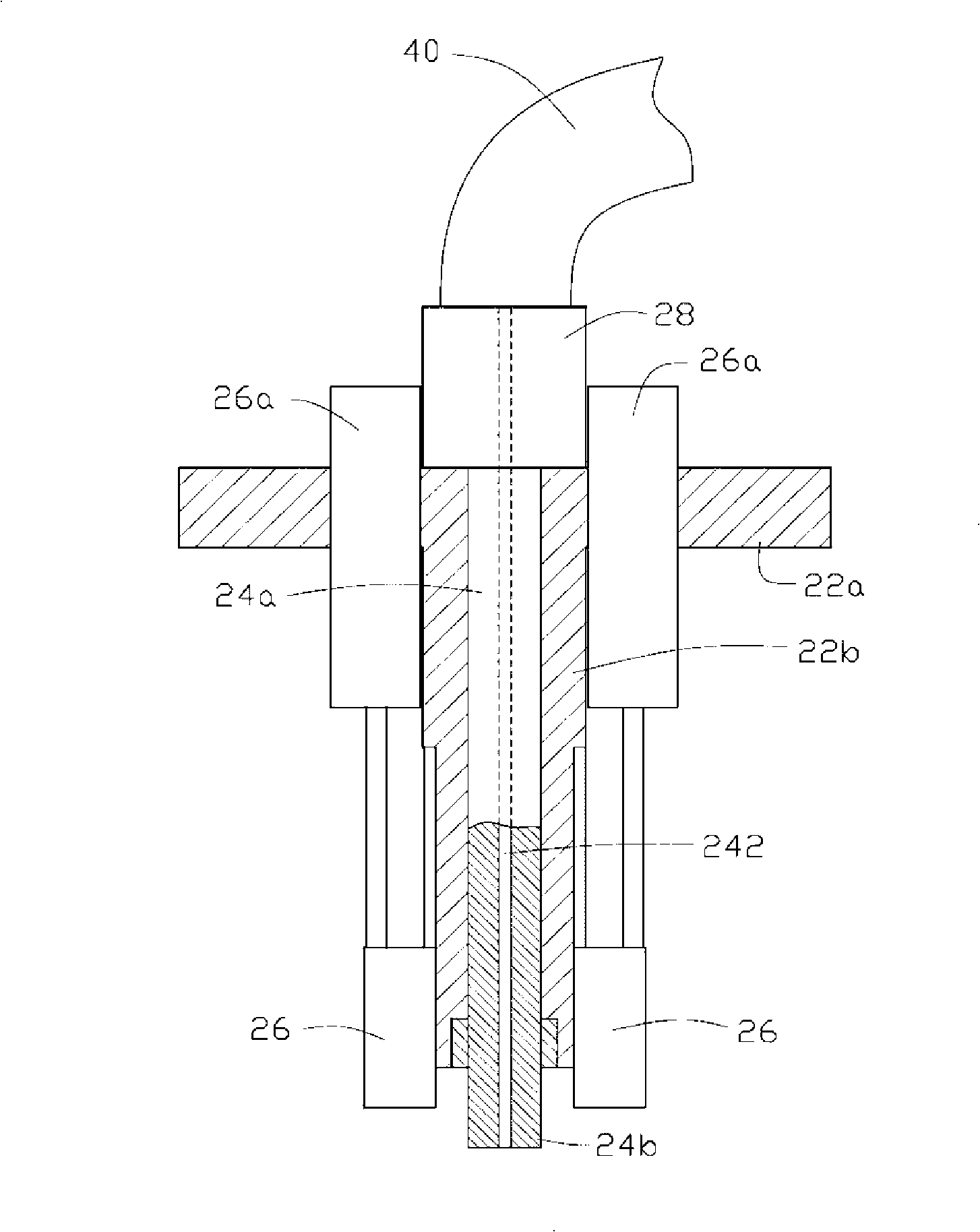

[0012] Please also refer to Figure 1 to image 3 , the lens module assembly system 100 provided by the embodiment of the present invention is used to assemble the lens barrel 200 and the base 300, which includes: a base alignment device 10 for aligning the base 300, and a mirror The barrel assembly device 20 is used for assembling the lens barrel 200 to the base 300 .

[0013] The lens barrel 200 includes a barrel body 210 and a retainer 220 located at the end of the barrel body 210 . The outer wall of the barrel body 210 is provided with an annular external thread, and the shape of the retainer 220 is circular. The lens barrel 200 may be pre-assembled with optical components such as lenses, diaphragms, and filters. The base 300 includes a cylindrical portion 310 and a frame portion 320, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com