Method of manufacturing printed circuit board for semiconductor package

A printed circuit board and semiconductor technology, applied in the field of PCB manufacturing, can solve problems such as defects, weakening of electroplating gold process, and deterioration of wire bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

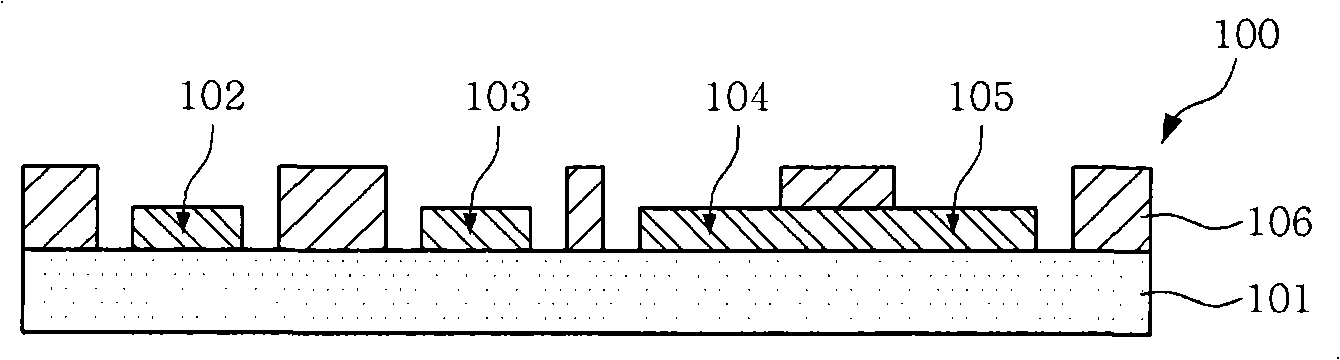

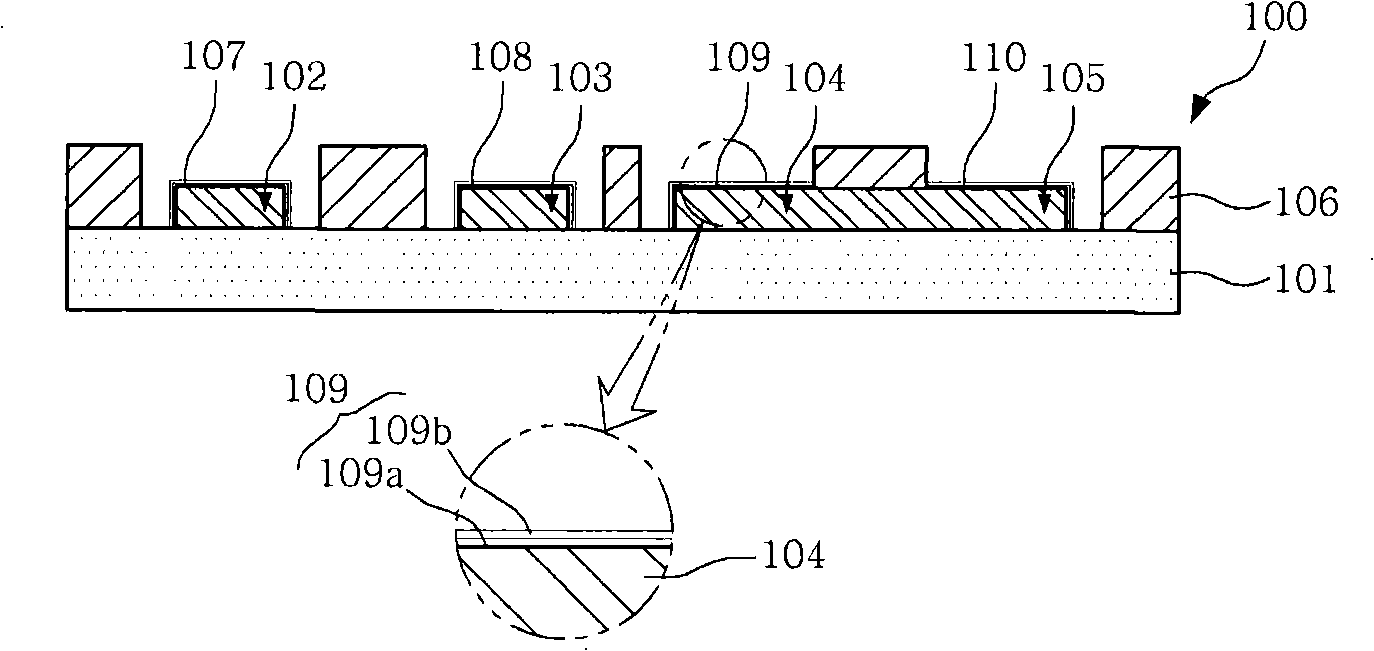

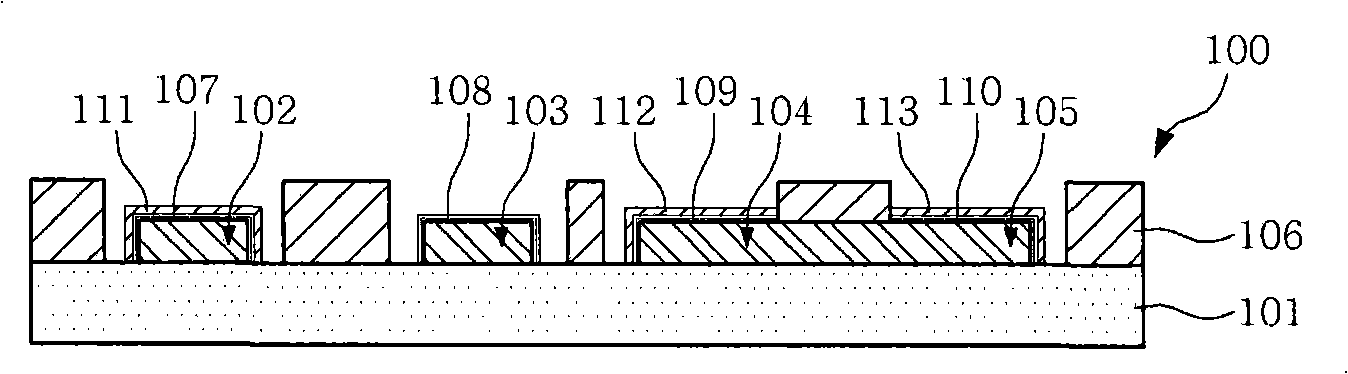

[0033] exist Figure 1A to Figure 1C In, a method for manufacturing a PCB for a semiconductor package according to a first embodiment of the present invention is schematically illustrated and described below.

[0034] According to a method well known in the art, a PCB 100 including a resin substrate 101, wire bonding pads 102, 105 and SMD mounting pads 103, 104 formed on the resin substrate and having a predetermined circuit pattern is prepared. In these figures, for simplicity of description, the inner layer structure of the substrate is omitted, and only a single side of the substrate is shown exemplarily, however any substrate, including double-sided, single-sided or multi-layer BGA or MLB substrates, may not be affected Applies to this limitedly. As with the resin substrate 101, any substrate including epoxy resin substrates, fluorinated resin substrates, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com