Self-cooled thyristor valve of high power and mounting vehicle

A thyristor valve, self-cooling technology, applied in the output power conversion device, emergency protection circuit device, electrical components and other directions, can solve the problems of affecting the transient performance of the system, difficult to maintain device update, large distribution parameters, etc. Conducive to rapid commutation, easy installation and maintenance, and small distribution parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure of the present invention will be described in detail below through embodiments and in conjunction with the accompanying drawings.

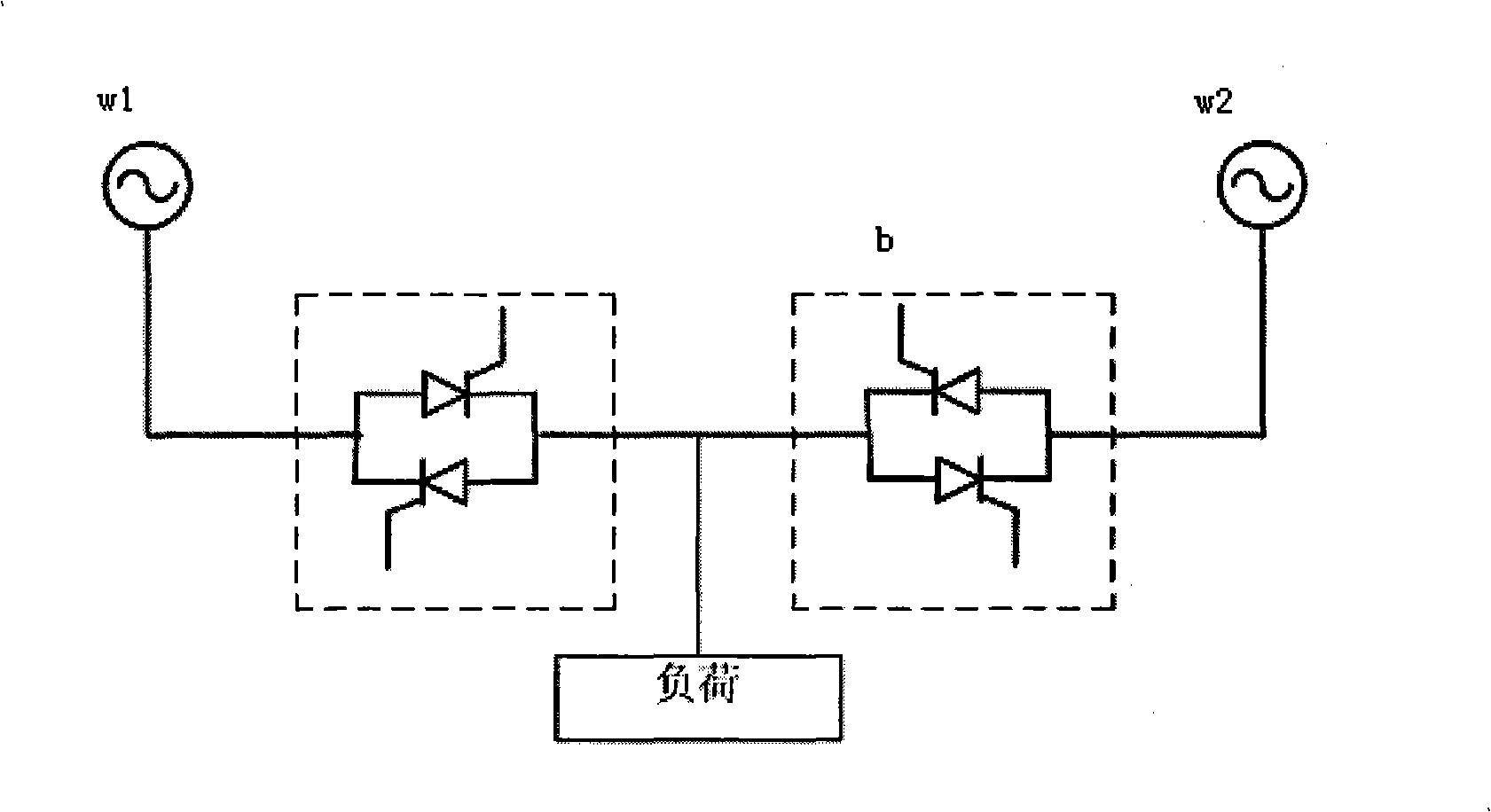

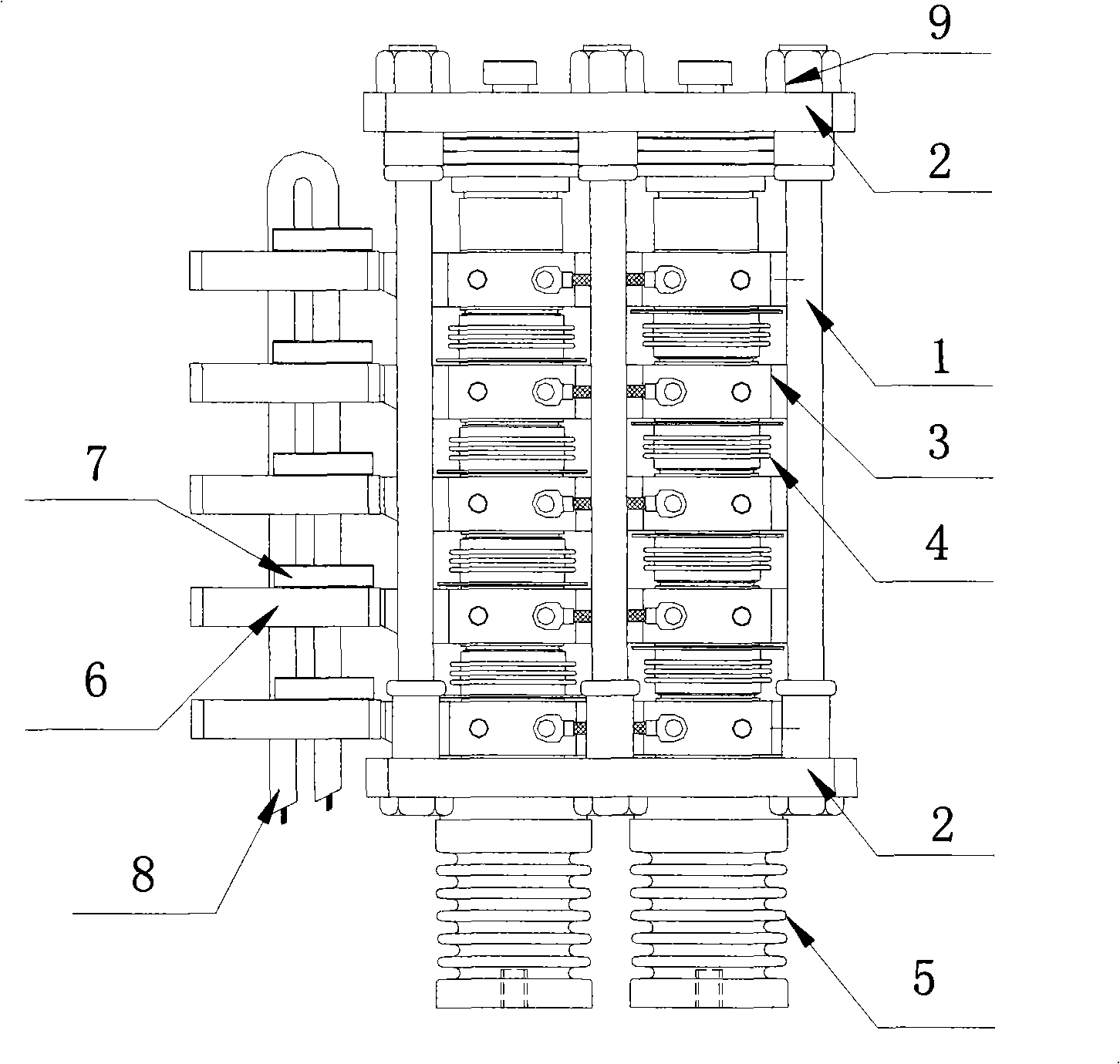

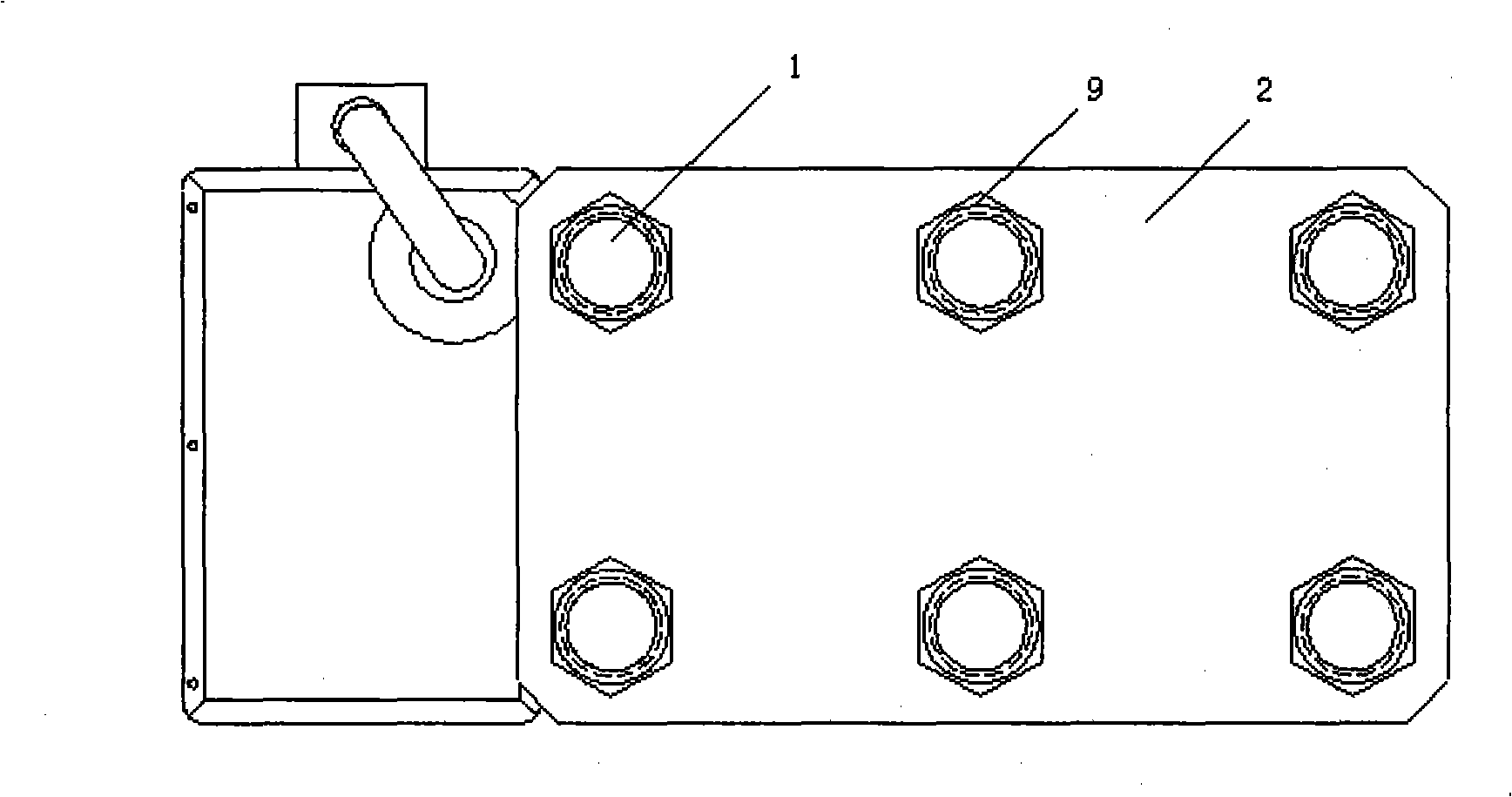

[0026] Such as figure 1 As shown, the solid-state transfer switch includes single-phase thyristor valve a and single-phase thyristor valve b, connected between the power supply w1 and the backup power supply w2, and the load is connected between the single-phase thyristor valve a and single-phase thyristor valve b. The working principle of the solid-state switch is that when the voltage fluctuation occurs in the power supply w1, the single-phase thyristor valve a is disconnected, the single-phase thyristor valve b is turned on, and the load is powered by the backup power supply w2. The present invention forms a thyristor valve unit by combining two forward and reverse thyristors connected in parallel, and a plurality of thyristor valve units are stacked vertically to form a thyristor valve string. Two sets of thyristor valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com