Apparatus for producing wood-wool and equipment thereof

A technology of wood wool and equipment, which is applied in the field of devices and equipment for preparing wood wool from veneer processing waste, which can solve the problems of insufficient rigidity of wood wool, poor strength of wood wool boards, waste of high-grade logs, etc., and overcome the weather resistance Defects, overcoming deformation, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

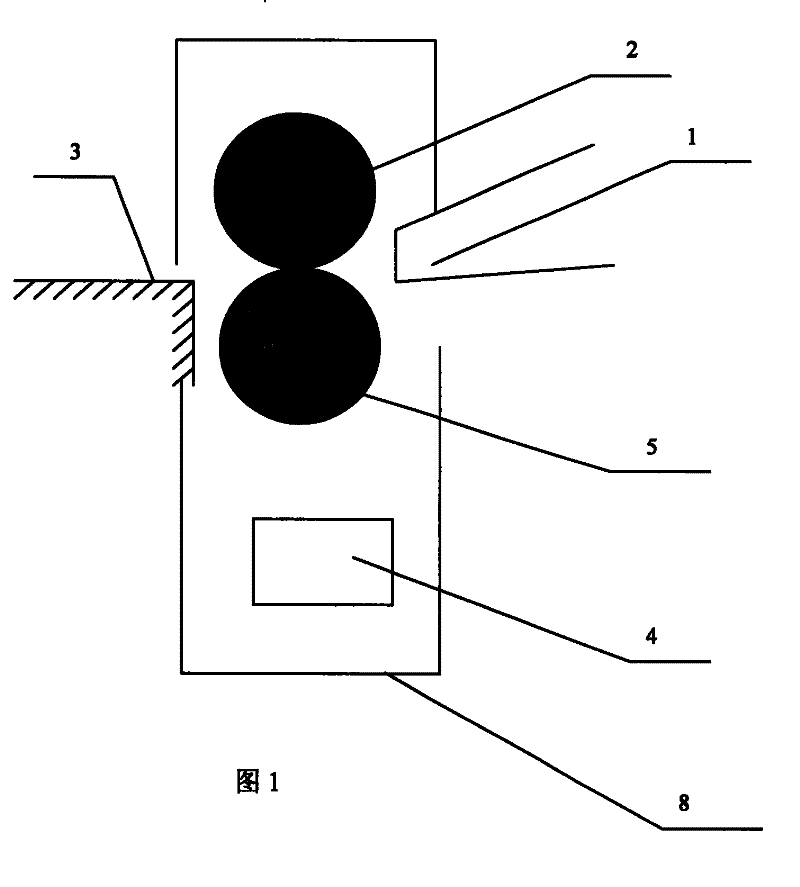

[0027] As shown in Figure 1, the wood wool production equipment of the present invention comprises casing 8, feeding device 1, discharge device 3, motor 4 and the upper combing roller 2 driven by motor 4, the lower combing roller 5, and the upper combing roller 5. Unwinding roller 2, following combing unraveling roller 5 and motor are arranged in the casing 8.

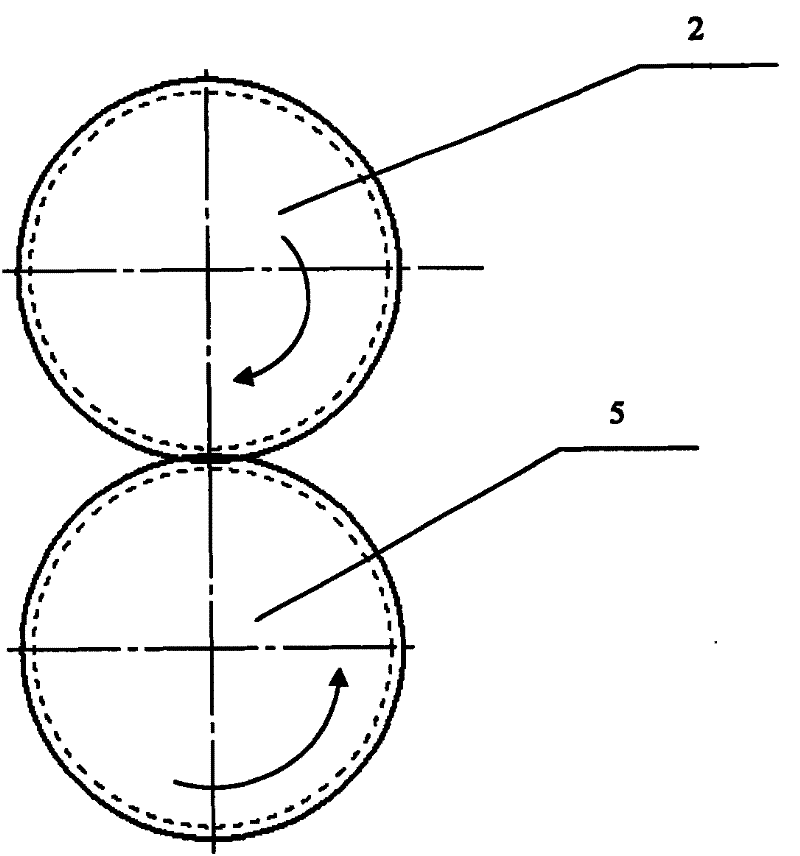

[0028] Among them, the paired combing rollers 2 and 5 are two cylindrical combing rollers that are placed up and down in the vertical direction and rotate synchronously in opposite directions; the central axes of the two combing rollers are parallel to each other, and the lower combing roller 5 is located on the upper combing roller. Roller 2 is directly below.

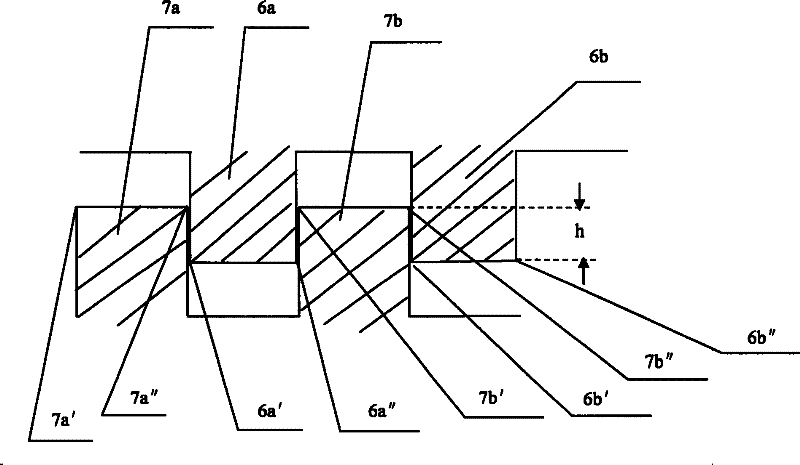

[0029] Such as figure 2 , 4 As shown, the upper combing roller 2 has a plurality of annular roller knives 6a, 6b parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com