Self-positioning permanent internal mold for cast-in-situ reinforced concrete structure and construction method thereof

A reinforced concrete and self-positioning technology, which is applied to building components, building structures, floor slabs, etc., can solve problems such as increased construction costs and complicated construction measures, and achieve the effects of improving construction efficiency, realizing engineering design intentions, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

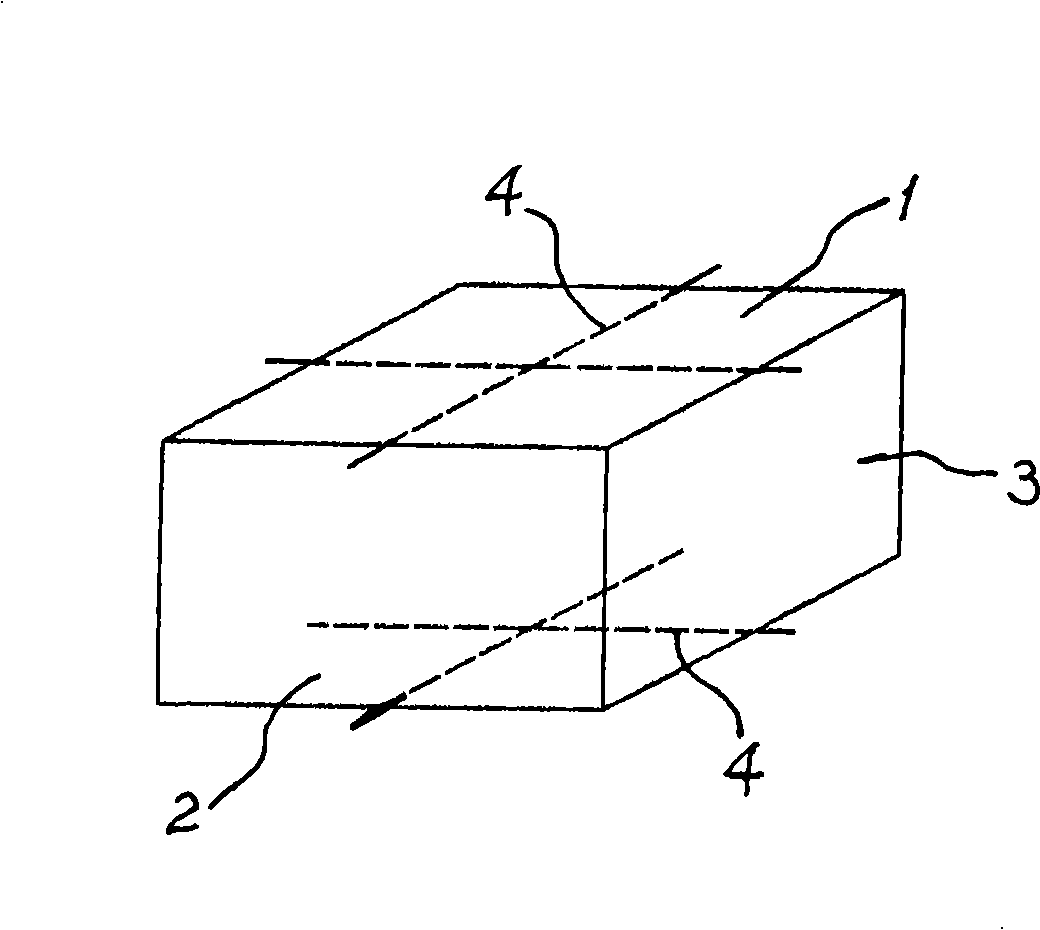

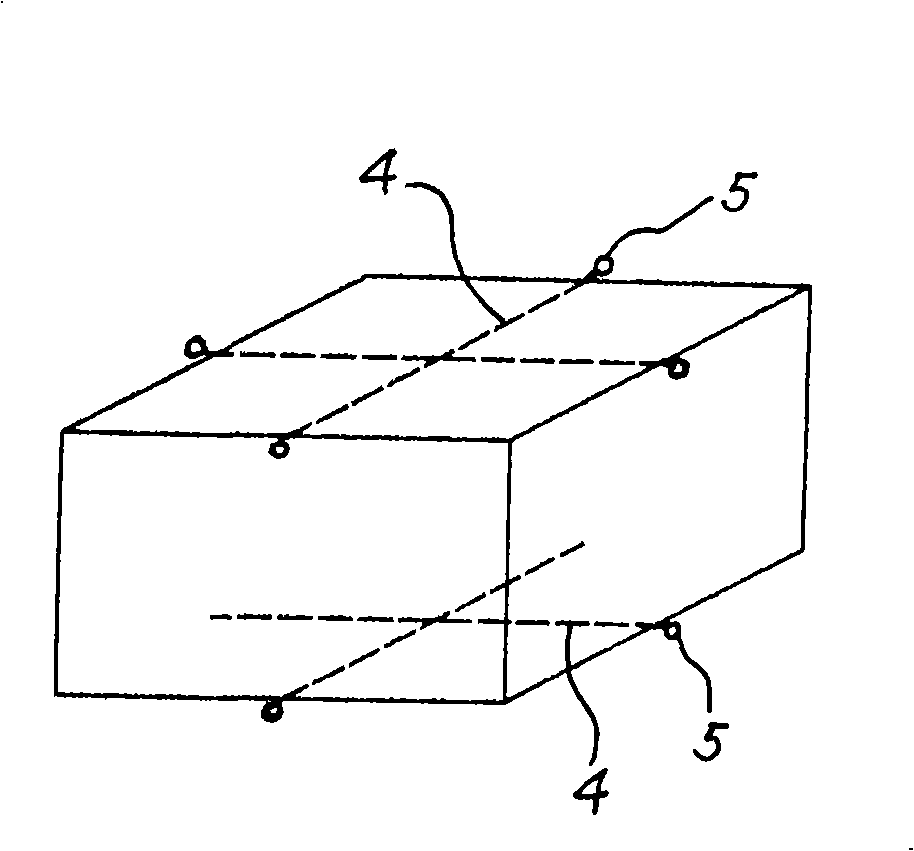

[0035] See Figure 1 to Figure 8 , The present invention is a self-positioning permanent internal mold for cast-in-situ reinforced concrete structures, which includes a top plate 1, a bottom plate 2 and four side walls 3. The top plate 1 and the bottom plate 2 are respectively pre-embedded with iron wires 4 for anti-floating and positioning, and the ends of each iron wire 4 protrude from the side wall 3 to connect and fix the top rib of the rib beam and the bottom rib of the rib beam.

[0036] Such as Figure 1 to Figure 4 As shown in the figure, the iron wires 4 are embedded in the top plate 1 and the bottom plate 2 in a cross shape, and the ends of each iron wire 4 protrude at the junction of the top plate 1 and the side wall 3 and the junction of the bottom plate 2 and the side wall 3, forming X-shaped spaces that are parallel and perpendicular to each other.

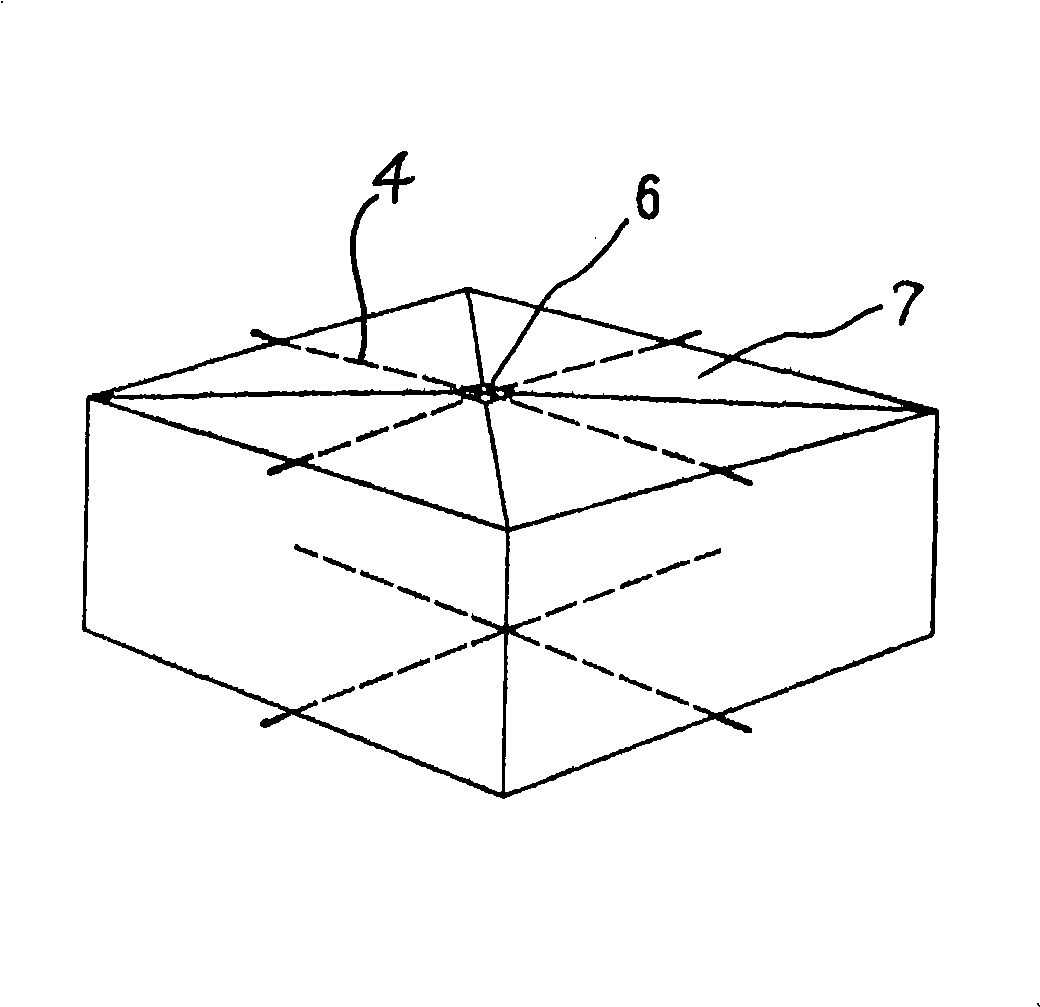

[0037] Another example Figure 5 to Figure 8 As shown in the figure, the iron wires 4 are linearly embedded on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com