Vertical axis aerogenerator with magnetic suspension for reducing gravity force and frictional force

A technology for wind turbines and generators, which is applied in the directions of holding devices, engine components, and shafts using magnetic attraction or thrust, can solve the problems of troublesome, cumbersome, complicated structure of magnetic suspension bearings, and achieves compact structure and simple overall structure. , avoid the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

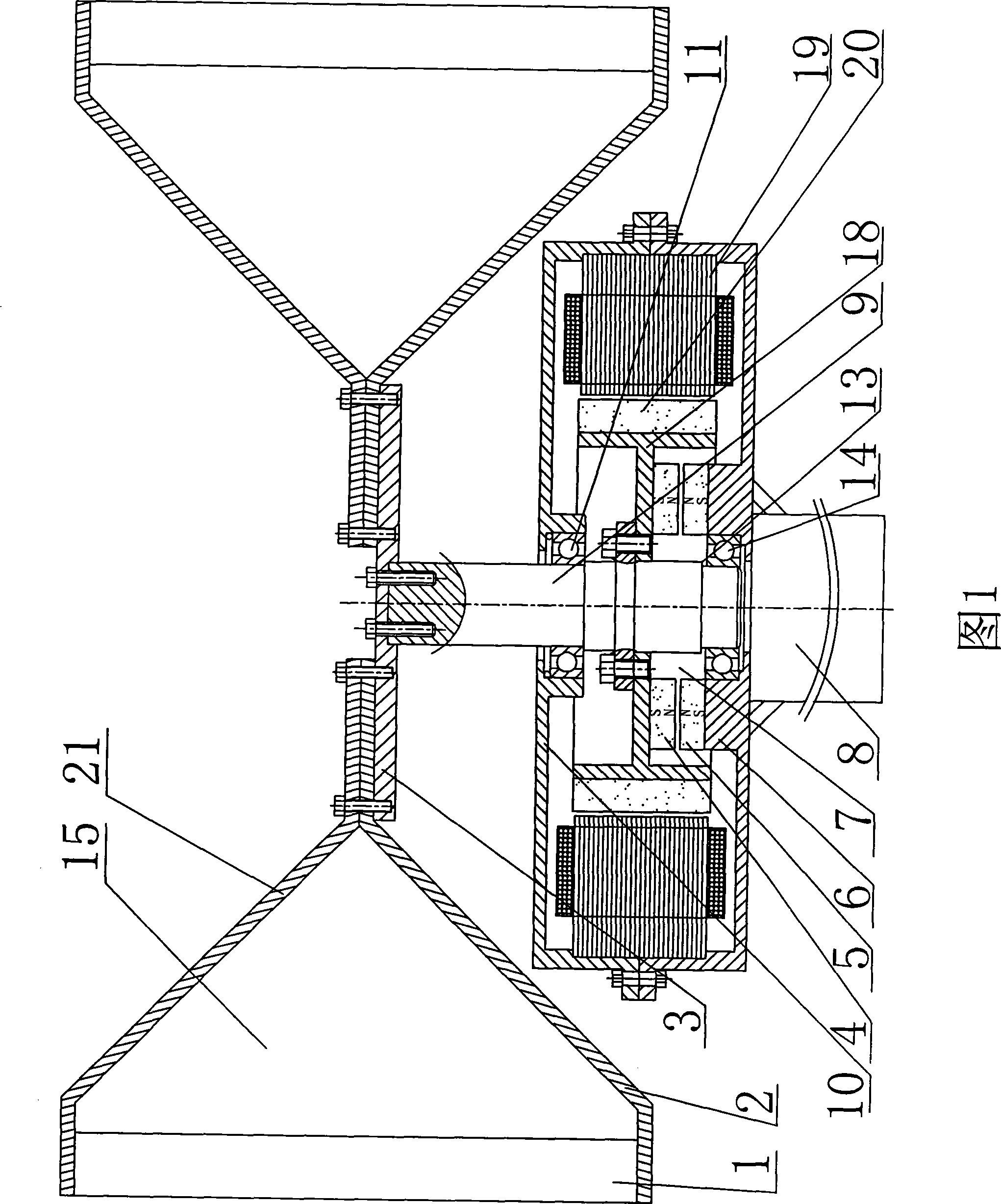

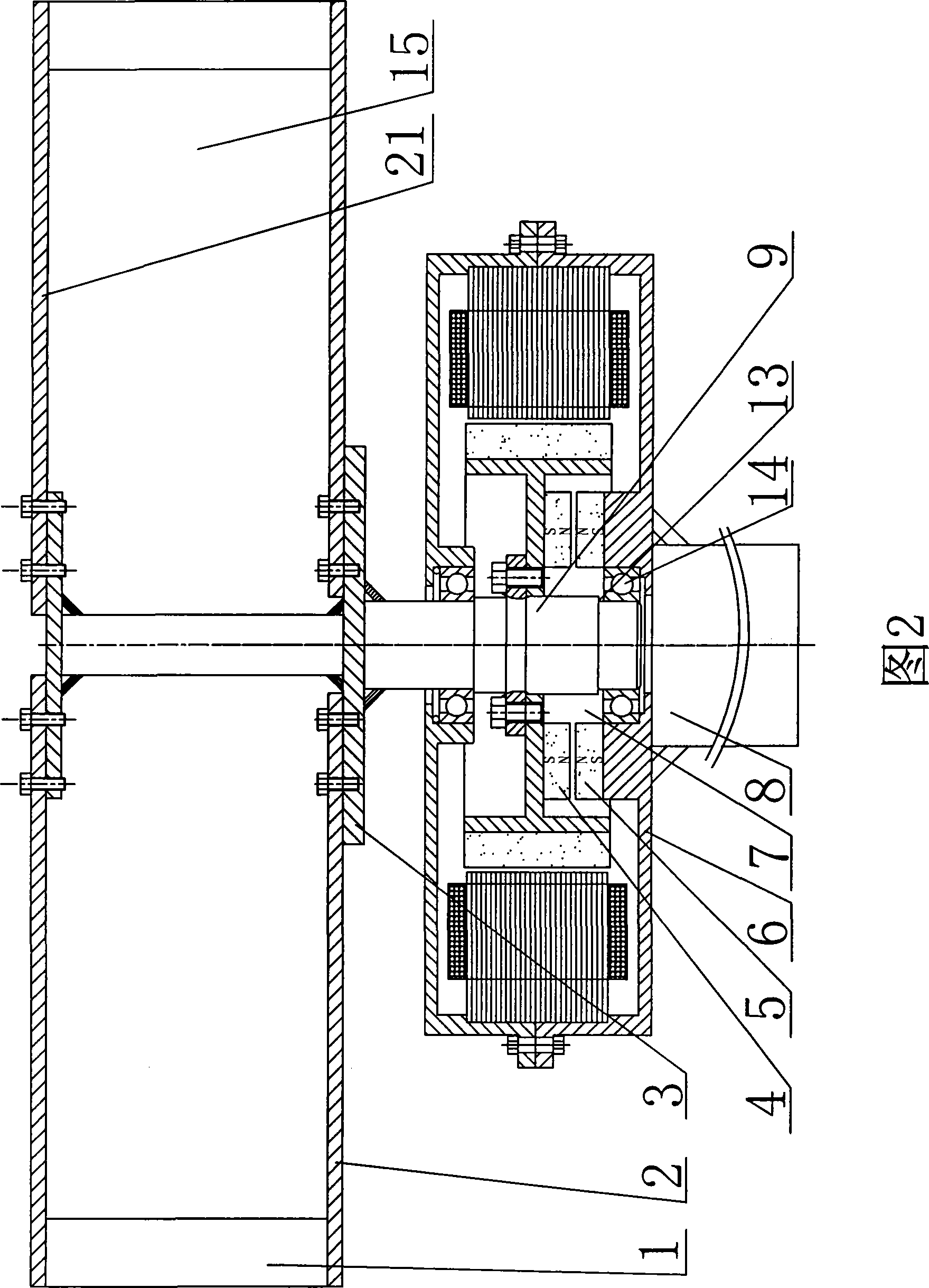

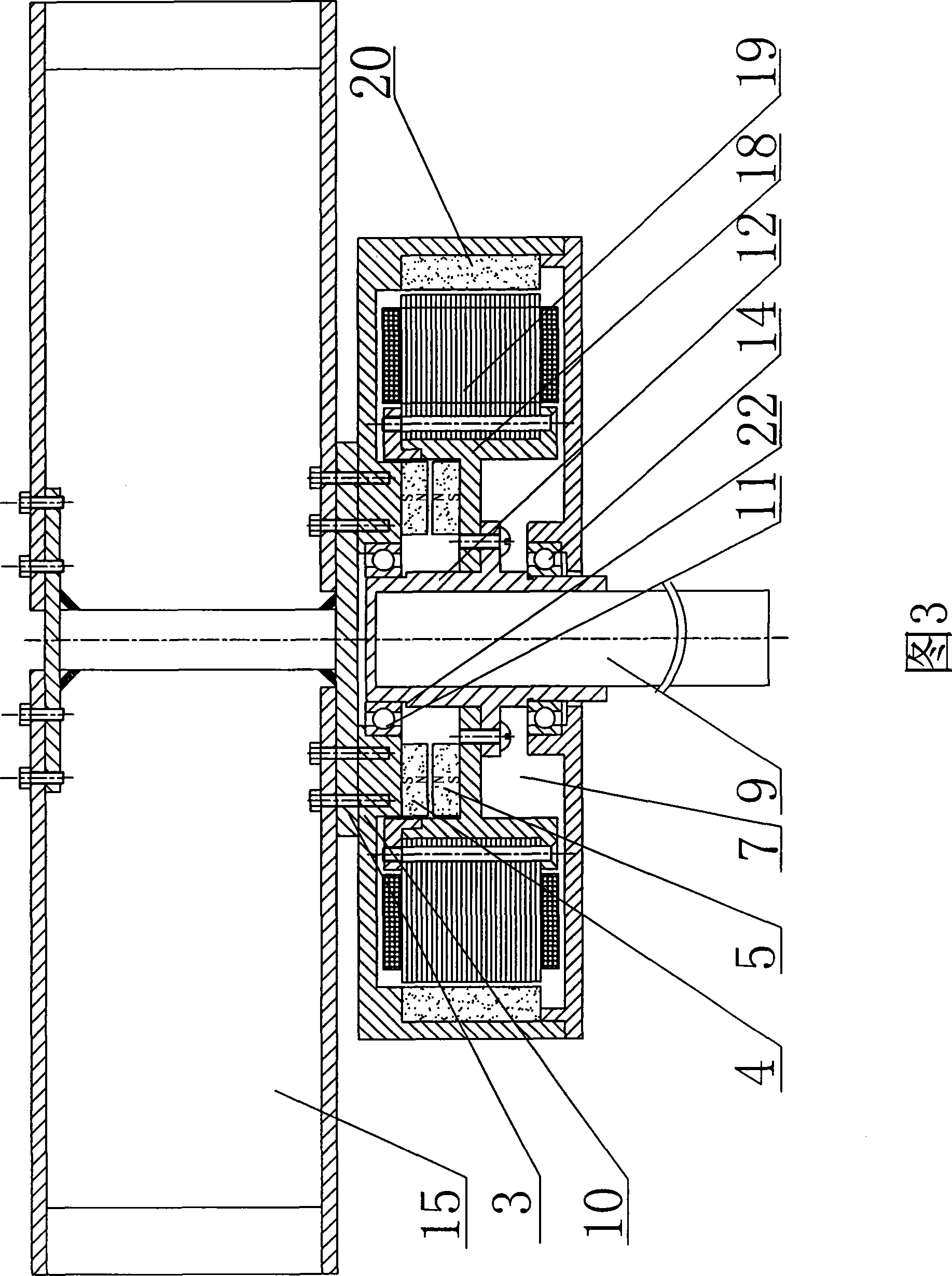

[0018] Description with reference to the accompanying drawings.

[0019] figure 1 Shown is an H-shaped wind wheel and an inner rotor generator. At this time, the generator shaft 9 is the rotor, and the upper end cover 10 and the lower end cover 6 of the generator are the stator. The upper and lower ends of the blade 1 of the wind wheel 15 are connected to one end of the upper arm 21 and the lower arm 2 respectively, and the other ends of the upper arm 21 and the lower arm 2 are connected together and connected to the lower flange 3 of the wind wheel 15, the lower flange The disc 3 is fixedly connected to the generator shaft 9 of the generator 7, the bracket disc 18 is fixedly connected to the collar of the generator shaft 9, the rotor magnetic pole 20 is fixed on the outer edge of the bracket disc 18, and the rotor permanent magnet 4 is fixed on the bracket On the frame plate 18, between the rotor magnetic pole 20 and the generator shaft 9, the stator permanent magnet 5 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com