Connecting rod for drawing system and loom comprising such a connecting rod

A technology for connecting rods and looms, applied in the field of connecting rods, can solve the problems of increasing the cost of shed forming devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

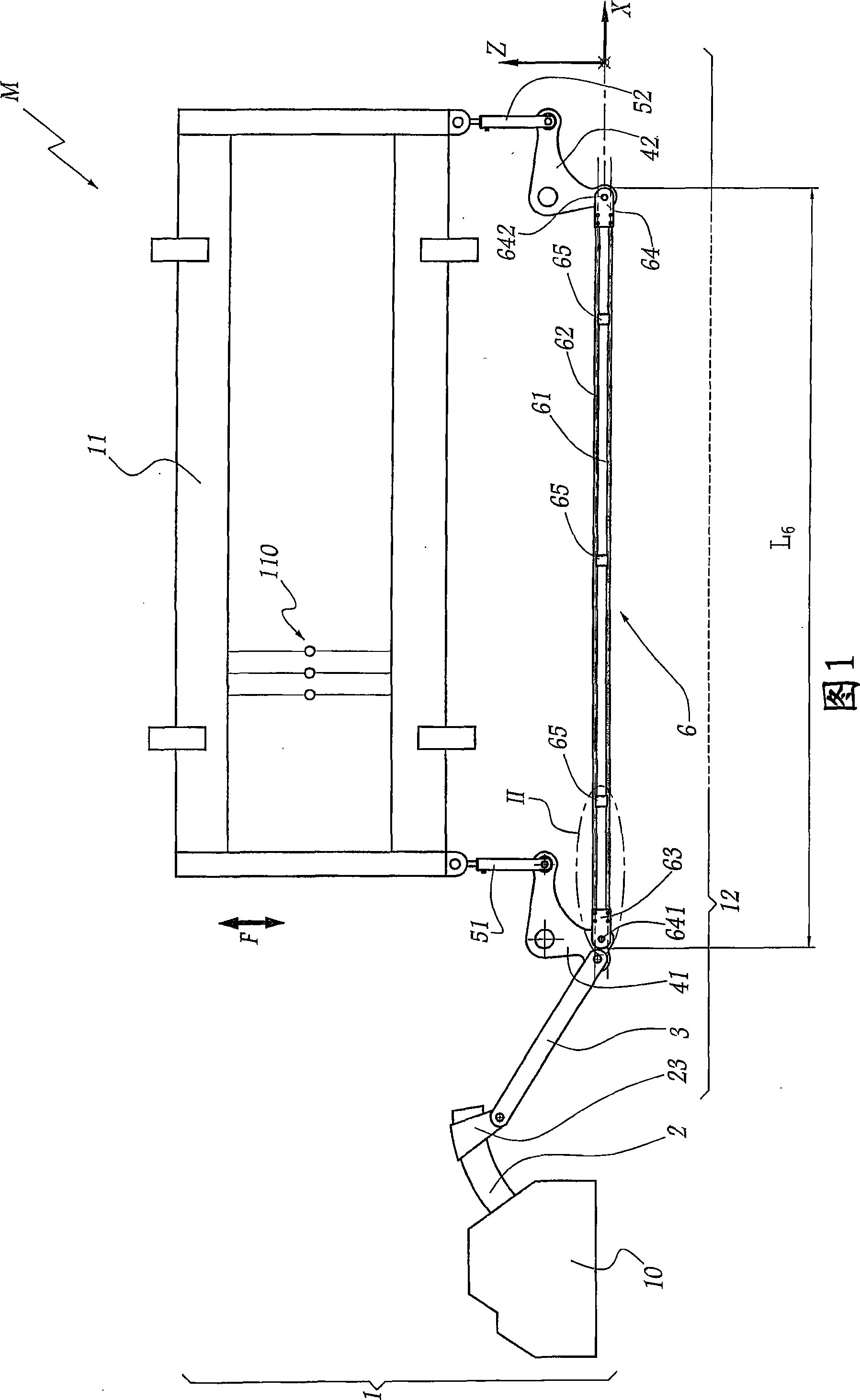

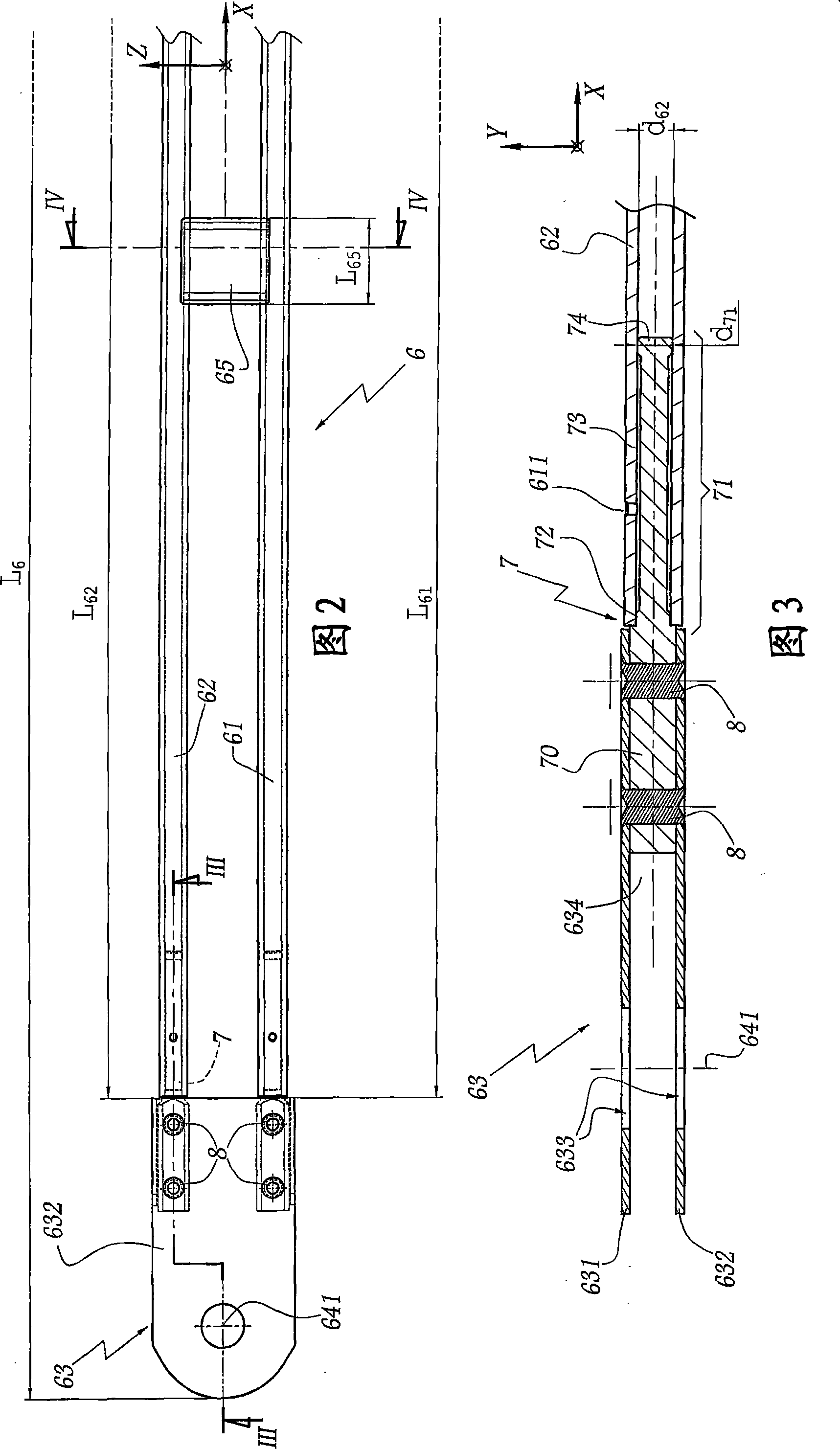

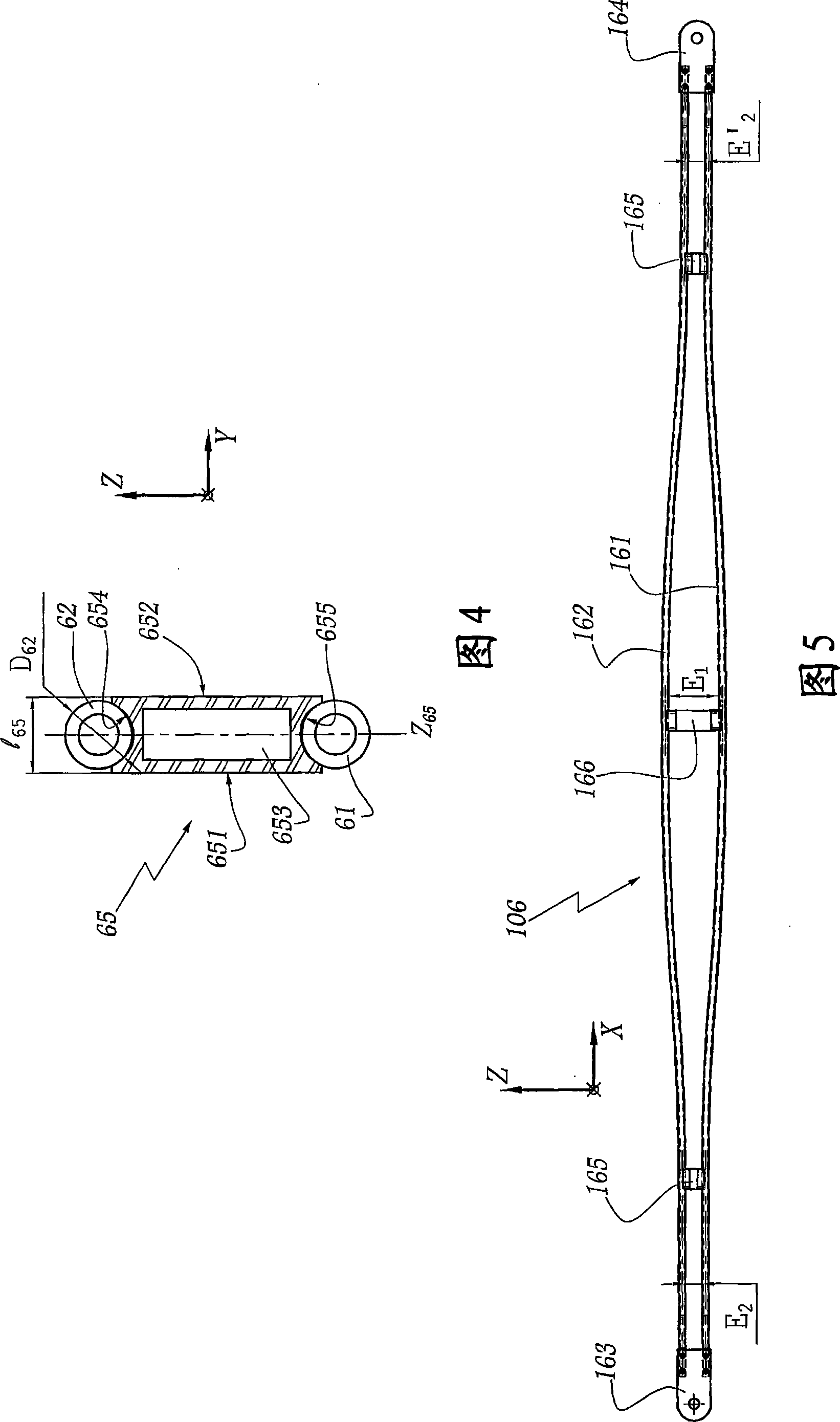

[0036] FIG. 1 shows a weaving machine M provided with a shedding device 1 comprising several heald frames, one of which is indicated at 11 in the figure. In a manner known per se, the heald frame 11 is equipped with a heald 110 , each eyelet of which is passed by a warp thread perpendicular to the plane of the heald frame 11 , ie the plane of FIG. 1 .

[0037] Each heald frame 11 is forced to move in the direction indicated by the double arrow F so as to oscillate vertically parallel to an axis. This motion is imparted by the dobby 10 . This movement is transmitted from the dobby 10 to the heald frame 11 by a series of connecting rods, levers and hooks forming the drafting system 12 .

[0038] The drafting system 12 is actuated by the output lever 2 of the dobby. The output lever 2 comprises a hook 23 placed on the output lever 2 and hinged to the first connecting rod 3 . The first connecting rod 3 in turn drives the left side oscillating lever 41 which drives the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com