Method and system for basement engineering water proof and water drain

A technology for drainage systems and basements, which is applied in water conservancy projects, infrastructure projects, artificial islands, etc., to achieve the effect of extending durability and reliability and improving waterproofing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

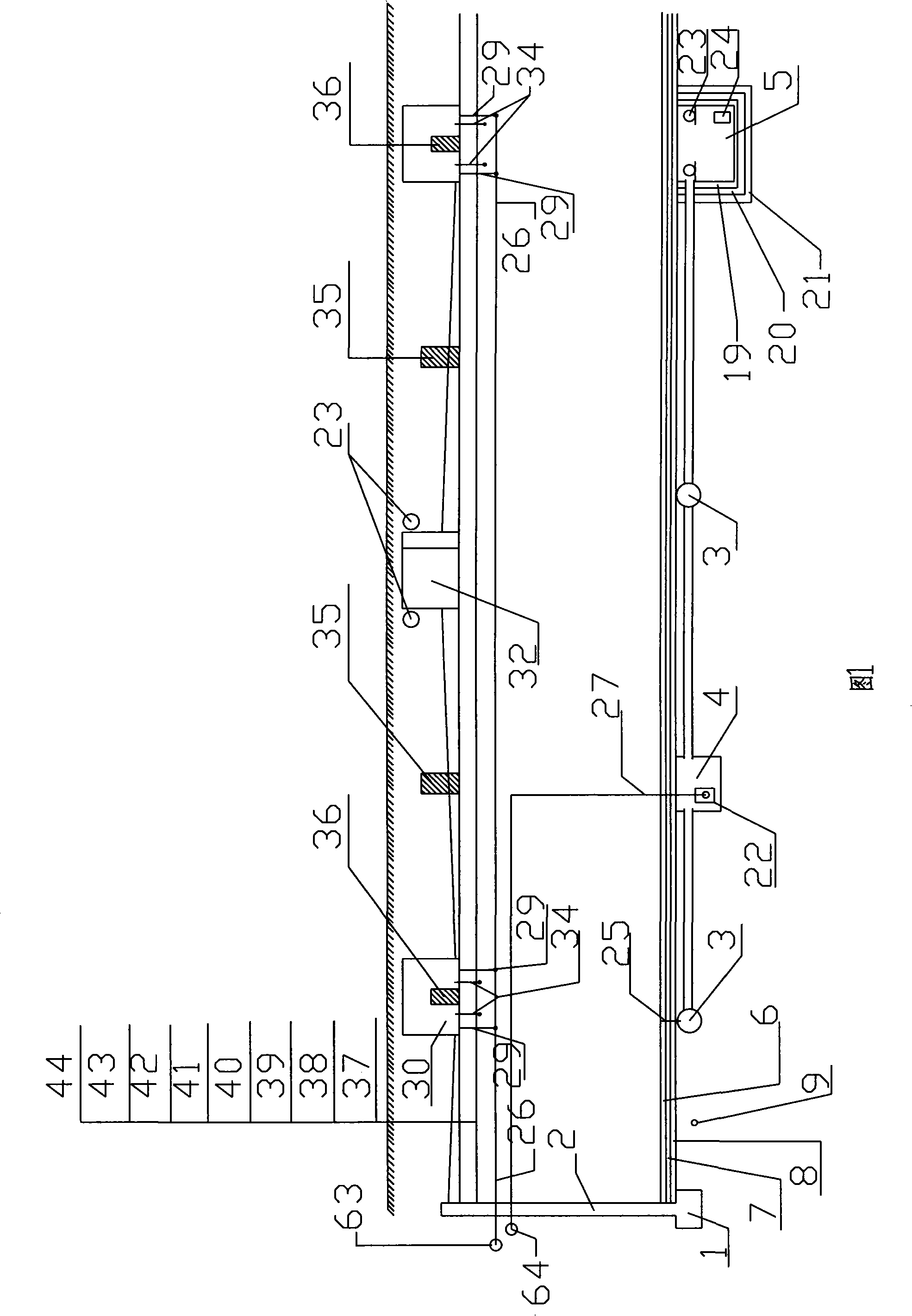

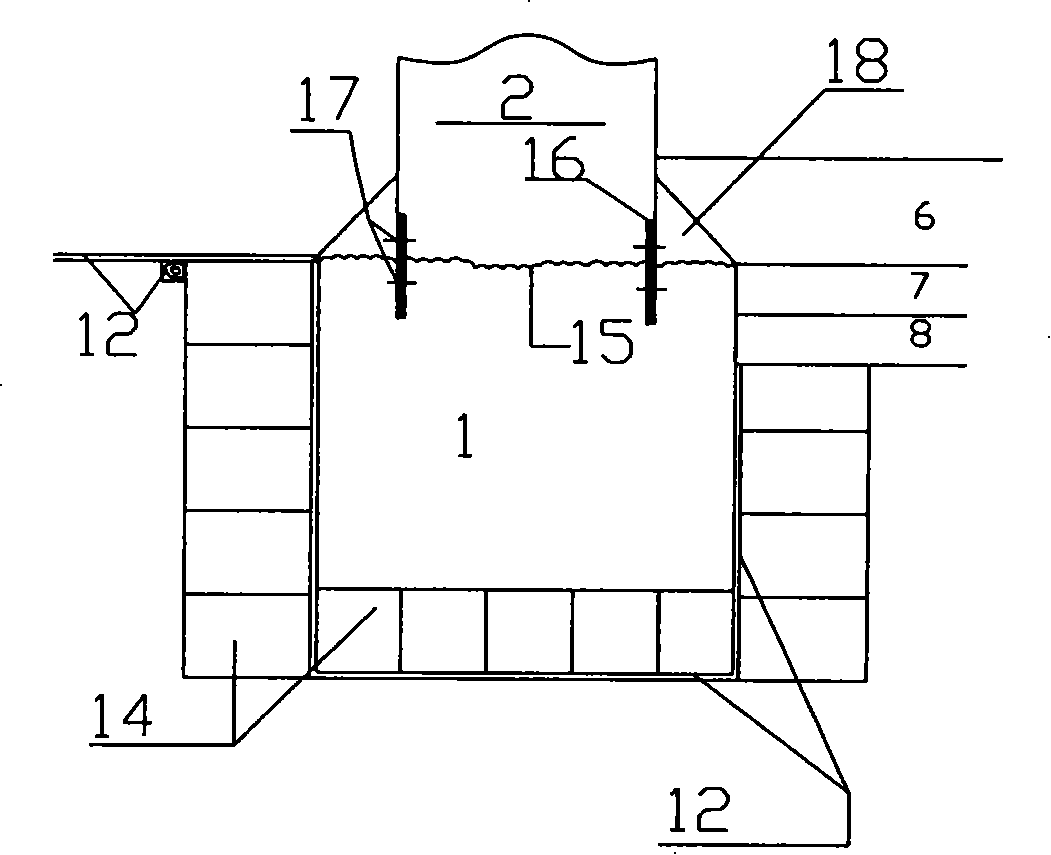

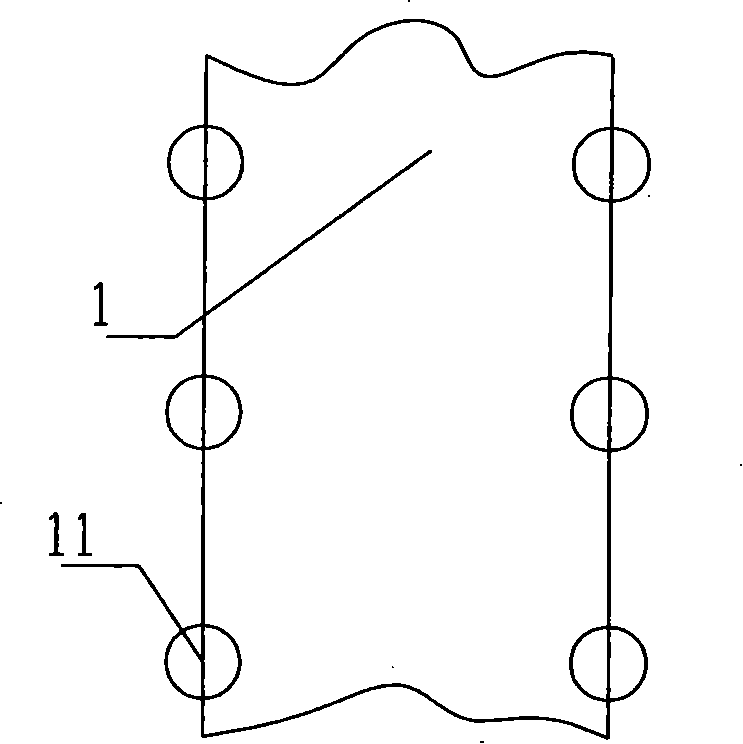

[0049] Such as figure 1 As shown, the wall base (1) of the basement engineering exterior wall (2) goes deep into the foundation (9) of the impervious or slightly permeable rock soil layer or soft soil layer to a certain depth, when the ground foundation (9) is a soft soil layer , the soft soil foundation should be treated in advance to form a continuous thick layer of cement soil, that is, the soil layer within a certain depth range under the basement project and the floor surface within the range of 2-5m outside is all reinforced with cement , forming a continuous impermeable cement-soil water-resisting layer in the horizontal direction and used as the bearing base of the bottom plate. The thickness of the cement-soil is at least greater than 1.5m.

[0050]The wall base (1) is supplemented with detailed water interception measures to prevent the groundwater outside the outer wall (2) from entering under the bottom plate (6) through the bottom surface of the wall base (1) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com