Directly-mounting type bar shape wiring block and slide tapping switch using the same

A tap changer, terminal board technology, applied in contact drive mechanism, transformer/inductor coil/winding/connection, transformer, etc., can solve problems such as bolt damage, pouring position, loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0006] Specific implementation mode one: the following combination Figure 5 and Figure 6 This embodiment will be specifically described. The direct-mounted strip wiring board of this embodiment is composed of a strip-shaped substrate 11 of insulating material, three to ten conductive sheets 12 and three to ten sets of wiring assemblies, and all the wiring assemblies are evenly distributed along the length direction of the substrate 11. Each set of wiring components includes screws 13-1 and conductive posts 13-2. The conductive posts 13-2 penetrate the upper and lower surfaces of the substrate 11 and are integrally injection molded with the substrate 11. The lower ends of the conductive posts 13-2 are connected to the screws 13-2. 1. Rotate and fix one end of the conductive sheet 12 between the lower surface of the substrate 11 and the screw 13-1, and the polished rod end of the conductive post 13-2 hangs out of the upper surface of the substrate 11. Since the end of the co...

specific Embodiment approach 2

[0008] Specific implementation mode two: the following combination Figure 5 and Figure 6 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that: the upper surface of the substrate 11 is provided with a tapered sleeve 11-3 surrounding the conductive column 13-2, the material of the tapered sleeve 11-3 is the same as that of the substrate 11, and the tapered sleeve 11-3 It is integrally molded with the substrate 11 and the conductive pillar 13-2. Such an arrangement improves the connection strength between the substrate 11 and the conductive pillars 13-2. Other compositions and implementations are the same as the first implementation.

specific Embodiment approach 3

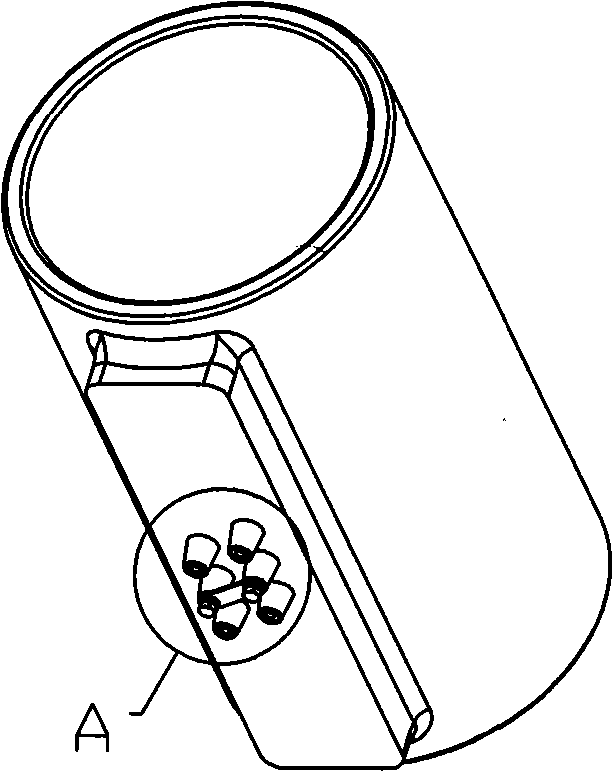

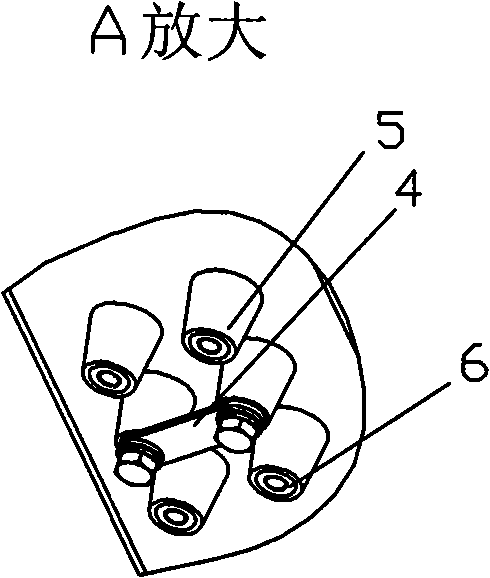

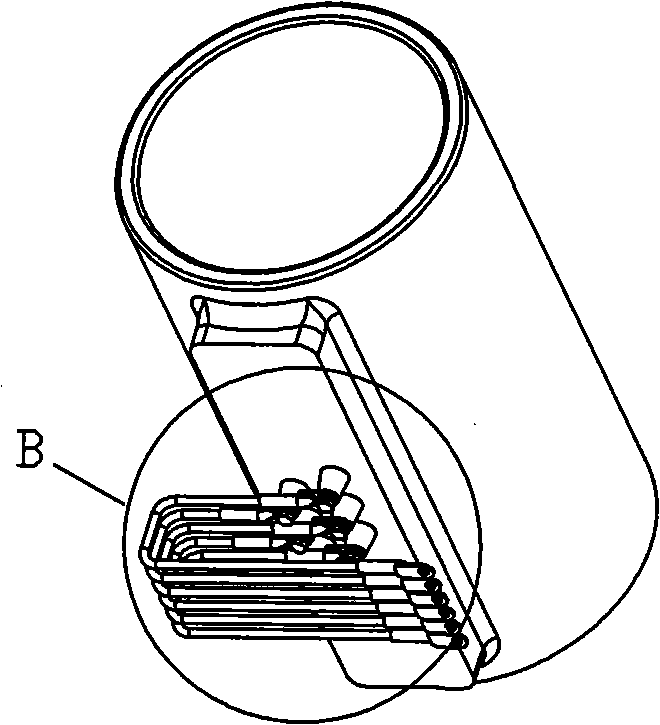

[0009] Specific implementation mode three: the following combination Figure 7 This embodiment will be specifically described. In this embodiment, the sliding tap changer using a direct-mounted strip terminal board is composed of a direct-mounted strip-shaped terminal board a, three to ten transformer terminal posts 5 and sliding contacts b, and all terminal posts 5 are distributed in On one side or both sides of the direct-installation strip terminal board a, the protruding end of the conductive piece 12 of the direct-installation strip terminal board a is fixed on the terminal post 5, and can slide through the direct-installation strip terminal board one by one. The length H of the conductive sheet of the sliding contact b on the outer cylindrical surface of the conductive posts 13 - 2 of the wiring board a is greater than the distance L between two adjacent conductive posts 13 - 2 and less than 2L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com