Process for the preparation of lyophilized piperacilline sodium with improved stability after reconstitution

A technology for drying piperacillin sodium and piperacillin is applied in the field of preparing freeze-dried piperacillin sodium, and can solve problems such as danger, serious patient and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

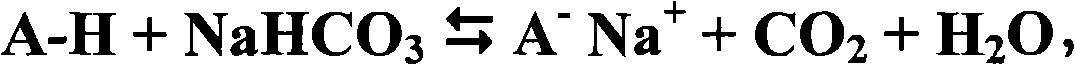

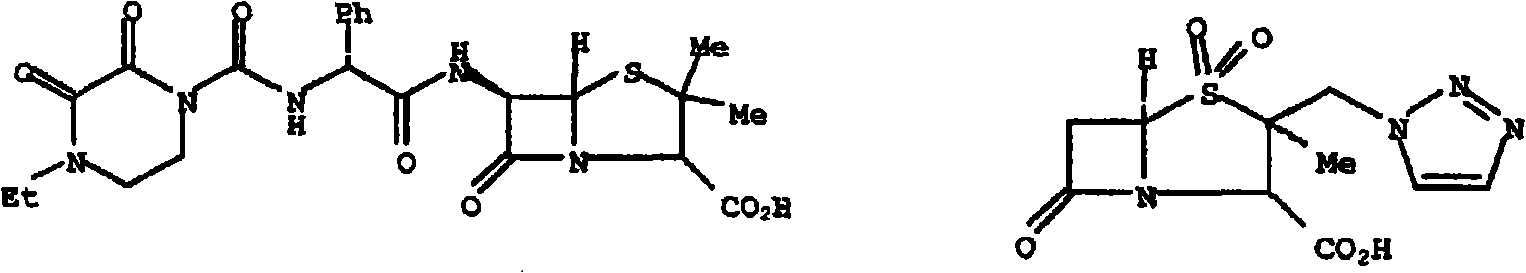

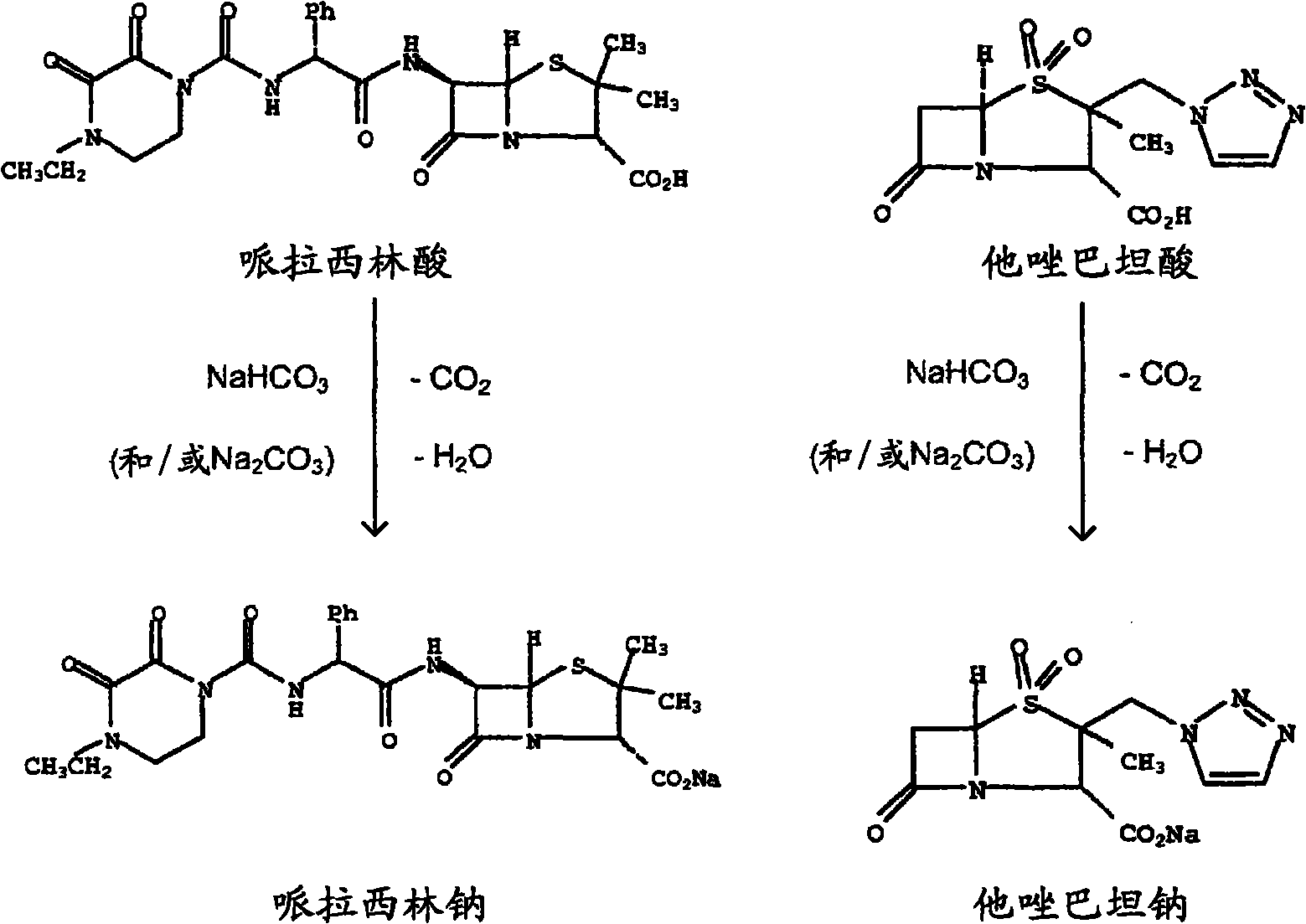

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] Into a 1 L stirred reactor was charged 109 mL of water, 60.00 g of piperacillin monohydrate (equivalent to 58.00 g of anhydrous acid; 11.2 cMol) and 7.25 g (2.4 cMol) of tazobactam (piperacillin with tazoba Tan ratio is 8:1). With good stirring, 11.43 g of sodium bicarbonate (13.6 cMol) were added in portions over 1 hour. Stirring was continued for 30 minutes while applying a vacuum of 20-30 mBar absolute. Determination of CO 2 Less than 75 mg / L (if higher, continue stirring under vacuum for another 30 minutes), adjust pH to 5.5-7.0 by adding piperacillin monohydrate (PIP) or sodium bicarbonate (BIC) if necessary. The solution was then lyophilized.

[0147] initial pH

Embodiment 2

[0149] To a 1 L stirred reactor was added 109 mL of water and 11.43 g of sodium bicarbonate (13.6 cMol). Lower the temperature to 6-9°C. Under good stirring, 60.00 g of piperacillin monohydrate (equivalent to 58.00 g of anhydrous acid; 11.2 cMol) and 7.25 g (2.4 cMol) of tazobactam (piperacillin and tazobactam) were added in portions within 1 hour. Tan ratio is 8:1). Stirring was continued for 30 minutes while applying a vacuum of 20-30 mBar absolute. Determination of CO 2 Less than 75 mg / L (if higher, continue stirring under vacuum for another 30 minutes), adjust pH to 5.5-7.0 by adding piperacillin monohydrate (PIP) or sodium bicarbonate (BIC) if necessary. The solution was then lyophilized.

[0150] initial pH

Embodiment 3

[0152] To a 1 L stirred reactor was added 109 mL of water and 11.43 g of sodium bicarbonate (13.6 cMol). Lower the temperature to 6-9°C. Under good stirring, 72.90 g (13.6 cMol) of piperacillin monohydrate was added in portions over 1 hour. Stirring was continued for 30 minutes while applying a vacuum of 20-30 mBar absolute. Determination of CO 2 Less than 75 mg / L (if higher, continue stirring under vacuum for another 30 minutes), if necessary, adjust the pH to 5.5-7.0 by adding piperacillin monohydrate (PIP) or sodium bicarbonate (BIC). The solution was then lyophilized.

[0153] initial pH

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com