Exhaust gas purification apparatus

An exhaust purification device, exhaust flow technology, applied in exhaust devices, mufflers, other chemical processes, etc., can solve problems such as difficulty in meeting emission control standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

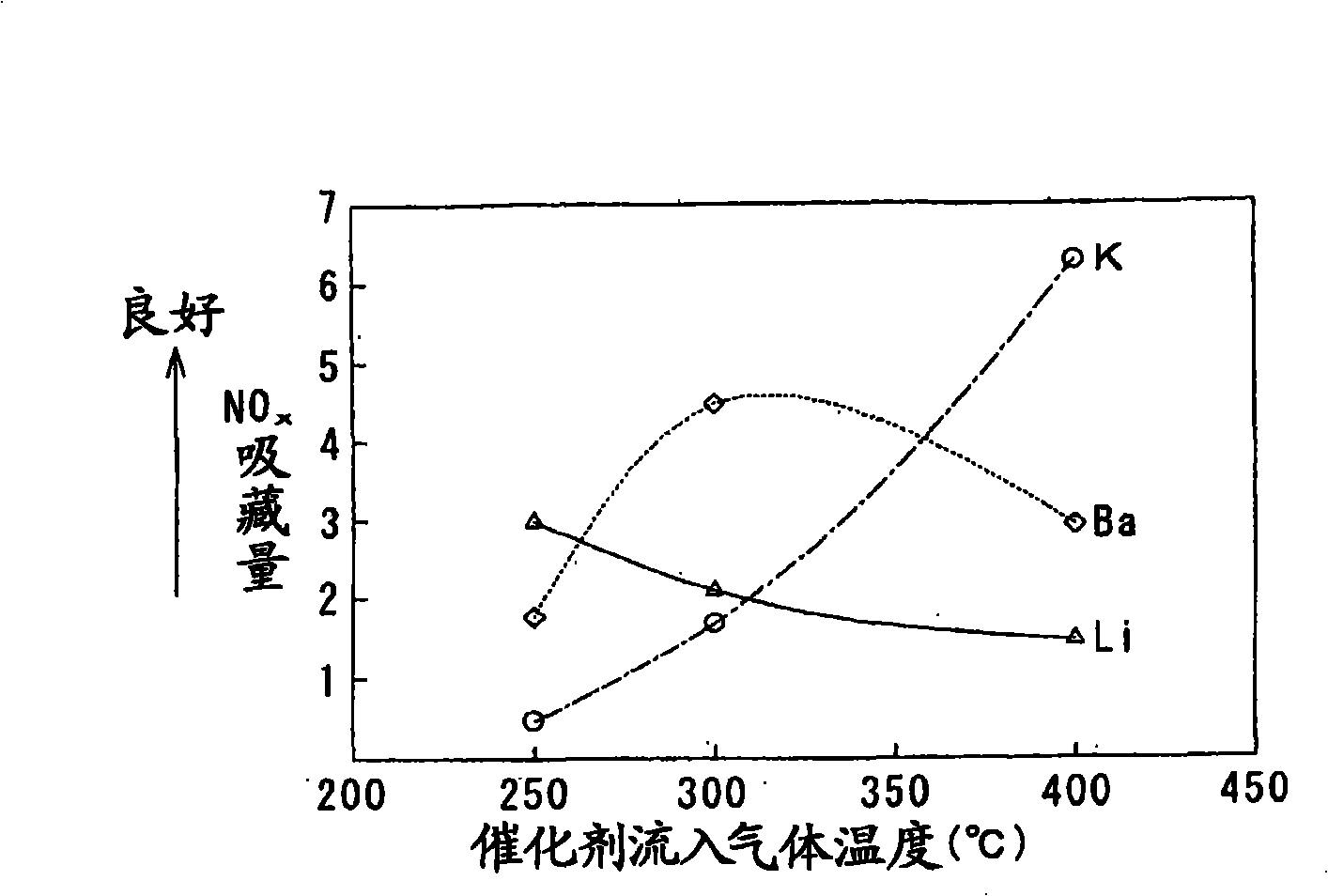

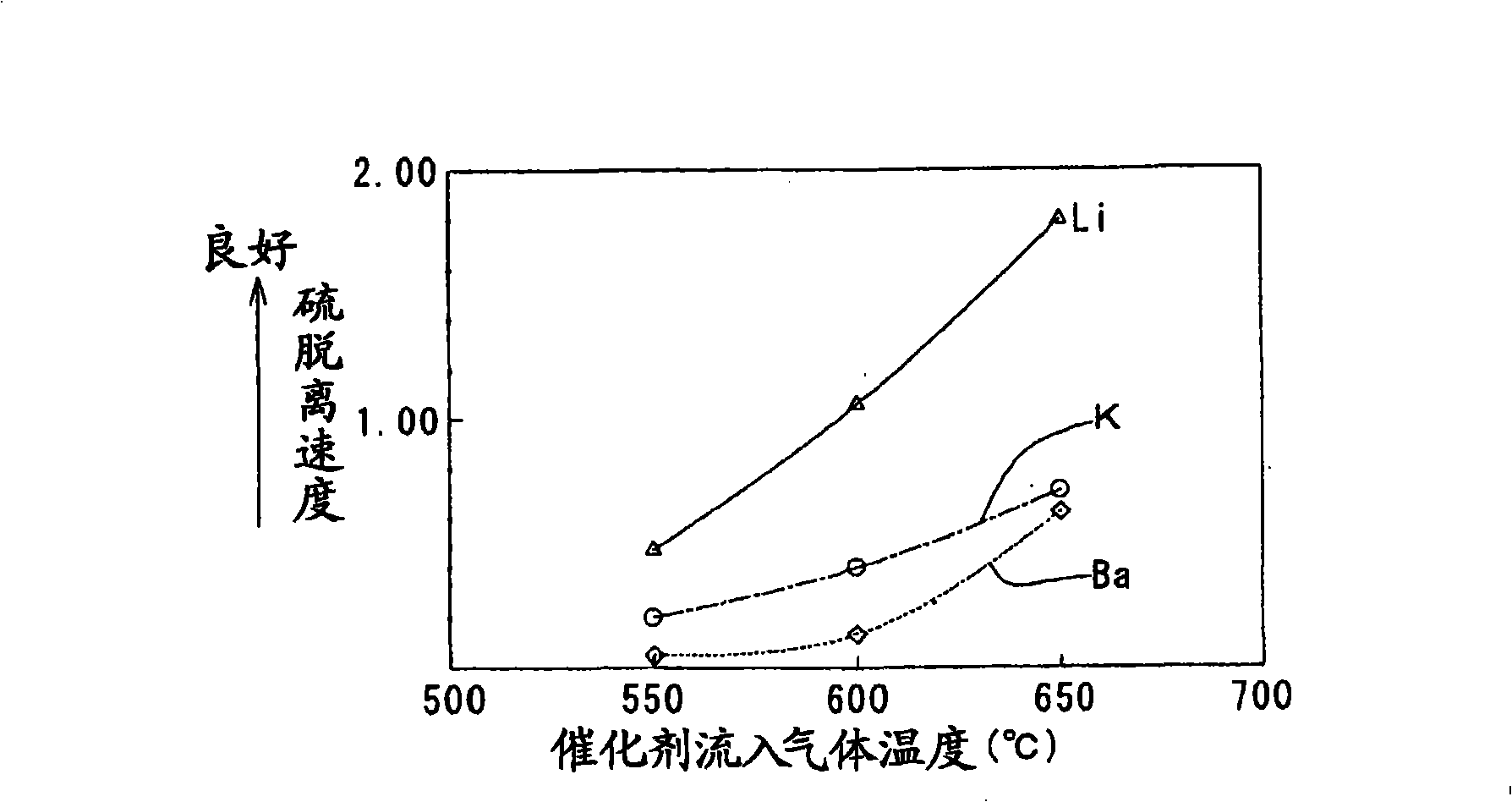

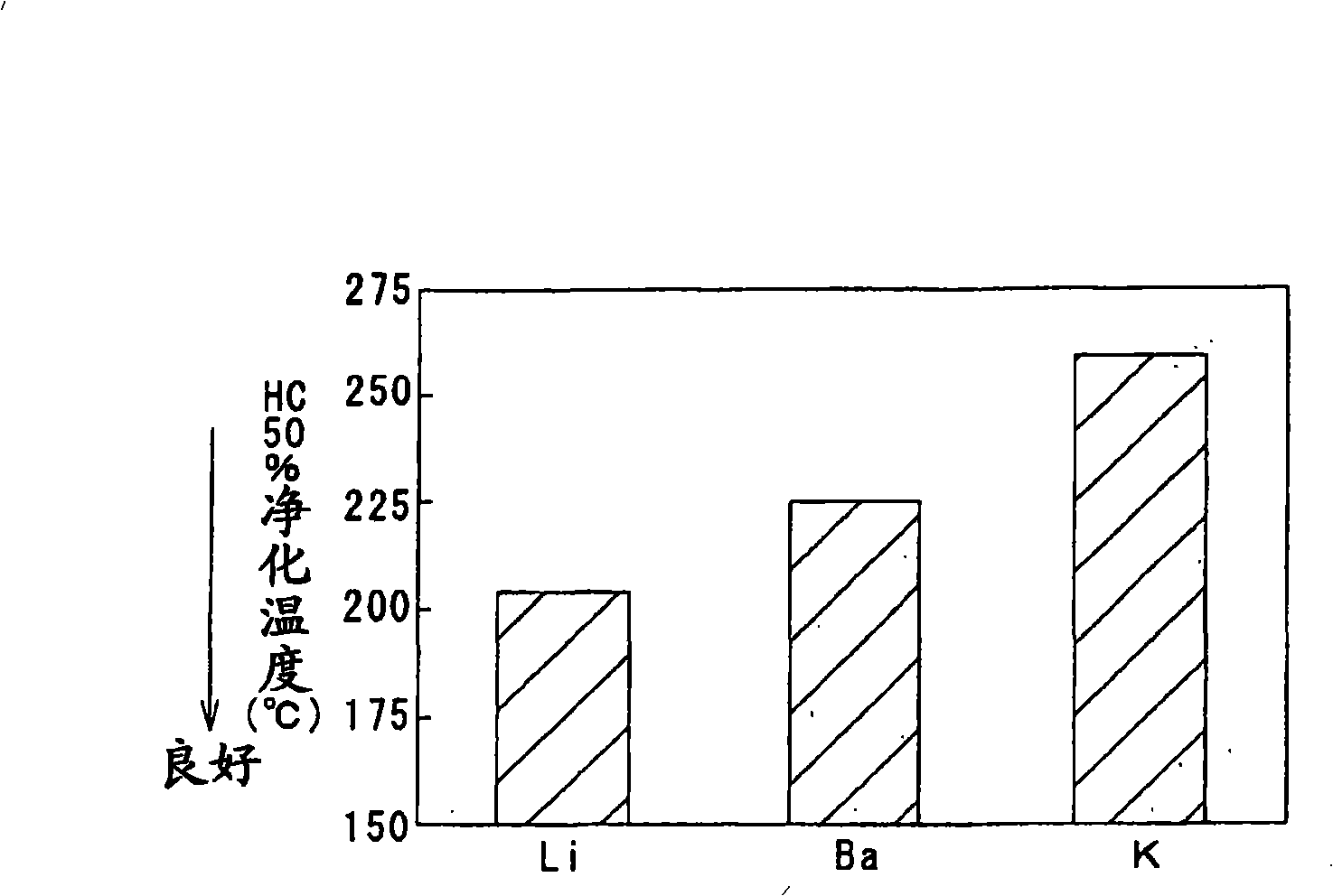

[0082] Based on the results of the above test examples, the Figure 4 exhaust purification device. This exhaust purification device is constituted by a catalytic converter 2 provided as an underfloor catalytic converter in an exhaust system of a diesel engine 1 having a displacement of 2000 cc. The catalytic converter 2 is composed of an upstream catalyst 3 , a midstream catalyst 4 and a downstream catalyst 5 arranged in series sequentially from the upstream side to the downstream side in the exhaust gas flow direction. The upstream catalyst 3 and the midstream catalyst 4 are NSR with a straight-flow structure, and the downstream catalyst 5 is a DPNR with a wall-flow structure. The catalytic converter 2 is provided with an injector 6 for adding fuel to the exhaust gas on the upstream side.

[0083] The upstream catalyst 3 supports 0.3 mol / L Li as the NOx storage material, and the midstream catalyst 4 supports 0.15 mol / L Ba as the NOx storage material. In addition, the downs...

Embodiment 2

[0094] Except that the upstream catalyst 3 supports 0.3 mol / L Mg as the NOx storage material, the midstream catalyst 4 supports 0.15 mol / L Sr as the NOx storage material, and the downstream catalyst 5 supports 0.3 mol / L Cs as the NOx storage material. Except for the materials, the manufacturing method of the exhaust purification device is the same as in Example 1.

Embodiment 3

[0096] In addition to the upstream catalyst 3 carrying 0.2mol Li and 0.05mol / L Mg as NOx storage materials, the midstream catalyst 4 carrying 0.075mol / L Ba and 0.075mol / L Ca as NOx storage materials, and the downstream catalyst 5 The manufacturing method of the exhaust purification device was the same as in Example 1 except that 0.15 mol / L of Cs and 0.15 mol / L of Na were supported as NOx storage materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com