Device for heating globular distillation flask

A distillation flask, spherical technology, applied in the direction of heating or cooling equipment, flasks, distillation separation, etc., can solve the problems that the distillation characteristics cannot meet the requirements, cannot ensure the correct positioning of the spherical flask, and the overall positioning is poor, and achieve simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

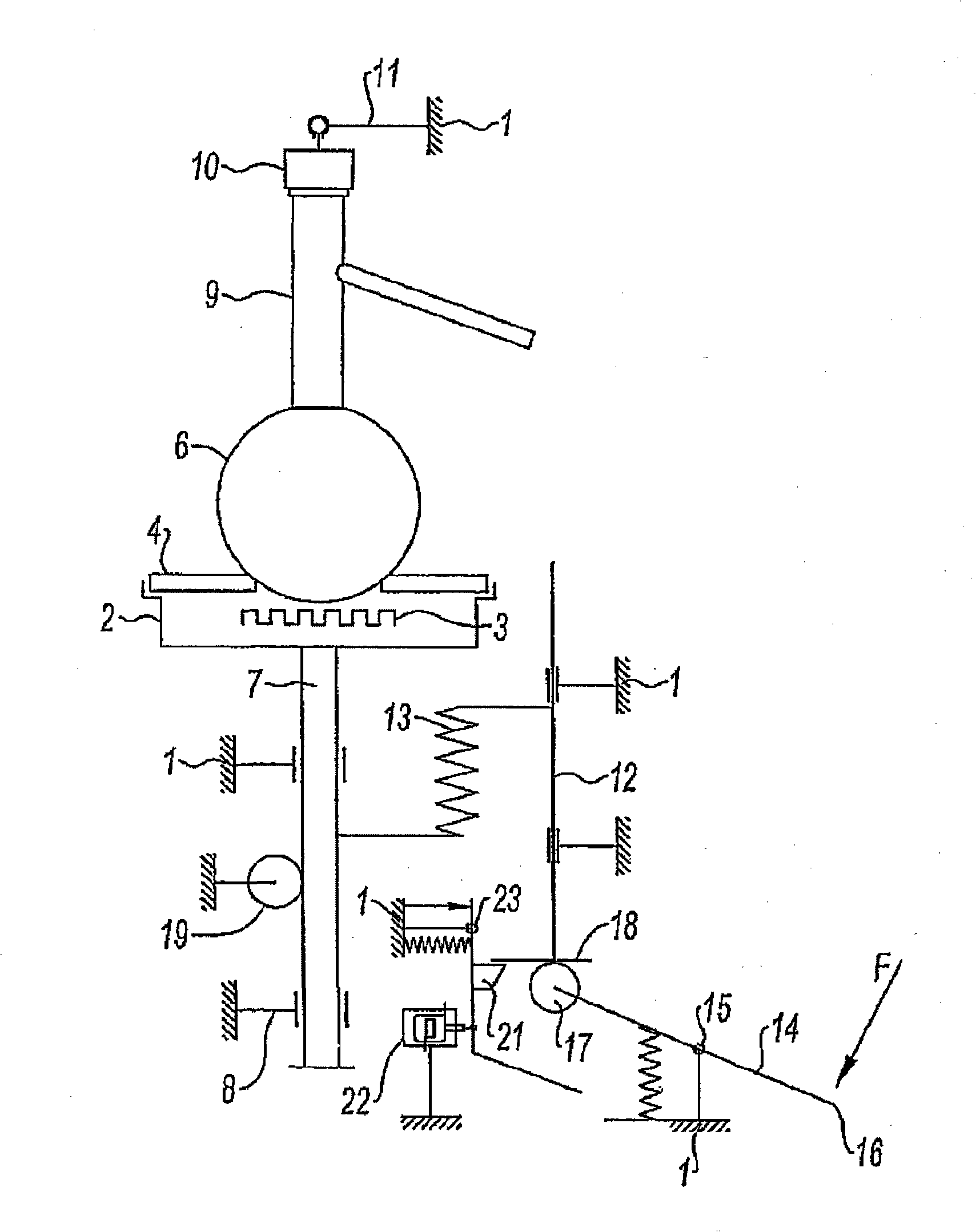

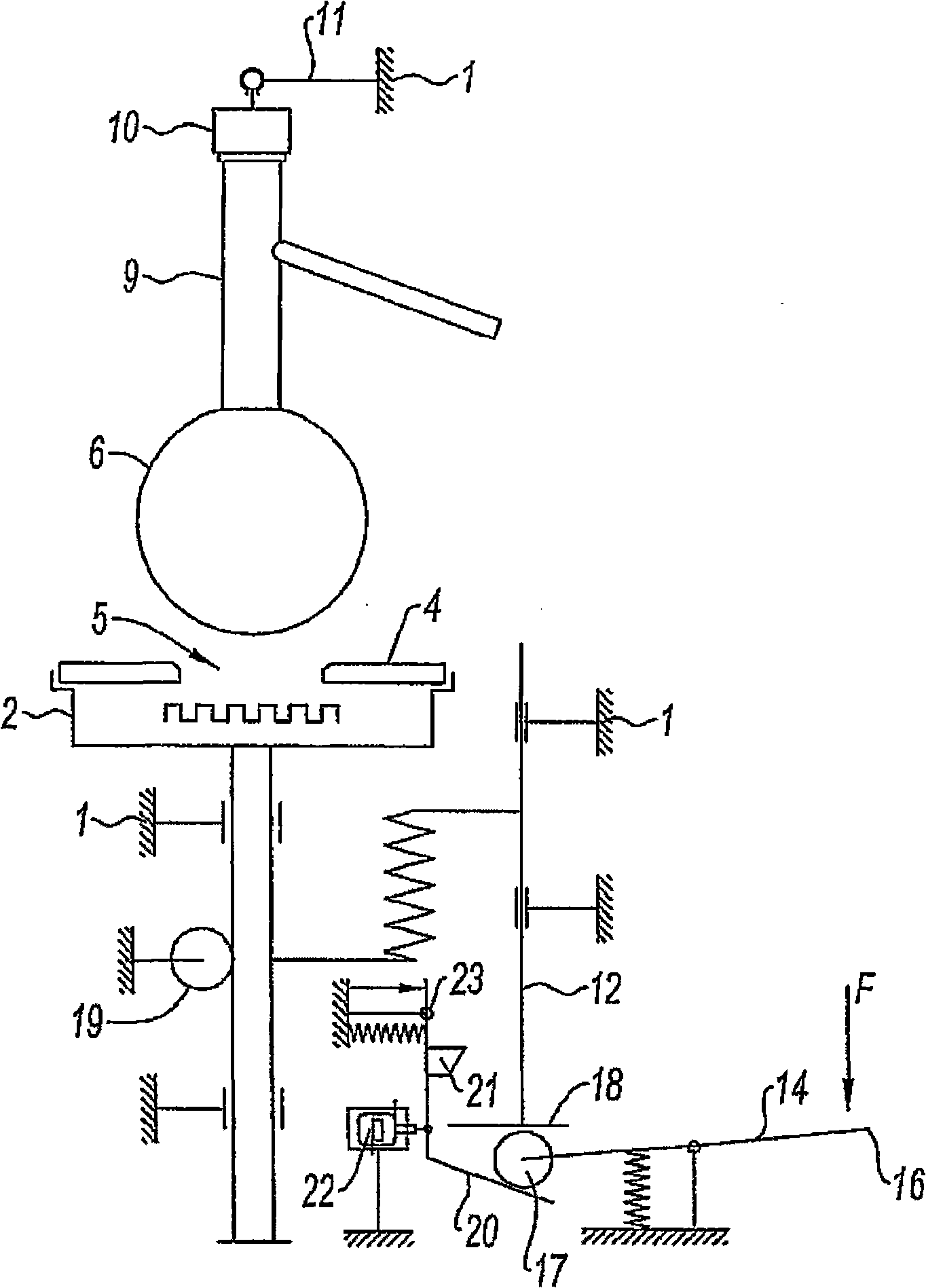

[0043] Such as figure 1 As shown, the device for heating a spherical distillation flask according to the present invention includes: a frame 1 on which a heating wall 2 is installed, and the heating wall 2 includes a heating component 3 .

[0044] The heating wall 2 is closed at its upper part by an insulating plate 4 provided with a central opening 5 for the bottom of said spherical distillation flask 6 .

[0045] The heating wall 2 is vertically movable between its two positions relative to the frame 1 of the distillation apparatus: i.e. figure 1 The high position (or operating position) shown in, in this position, insulation plate 4 keeps supporting this spherical distillation flask 6; And, figure 2 The low position (or stop position) shown in .

[0046] In order to facilitate the movement between the above two positions, the heating wall 2 is provided with a transfer column 7 at its lower part, which cooperates with the guide device 8 connected to the equipment frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com