Method for manufacturing pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire treads/tread patterns, tires, etc., can solve problems such as deterioration, time-consuming, large steps, etc., to prevent deterioration, prevent molding defects, reduce effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

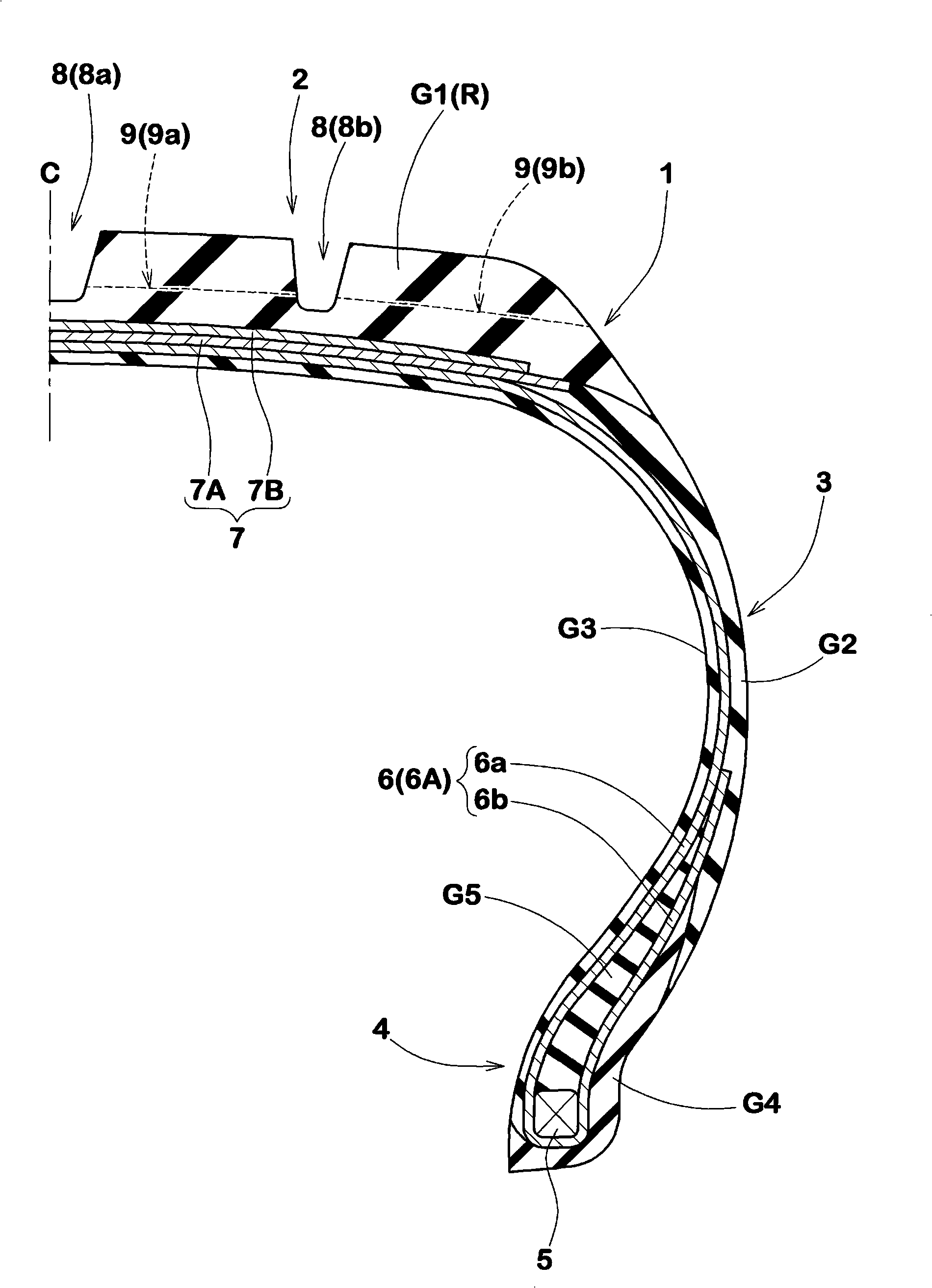

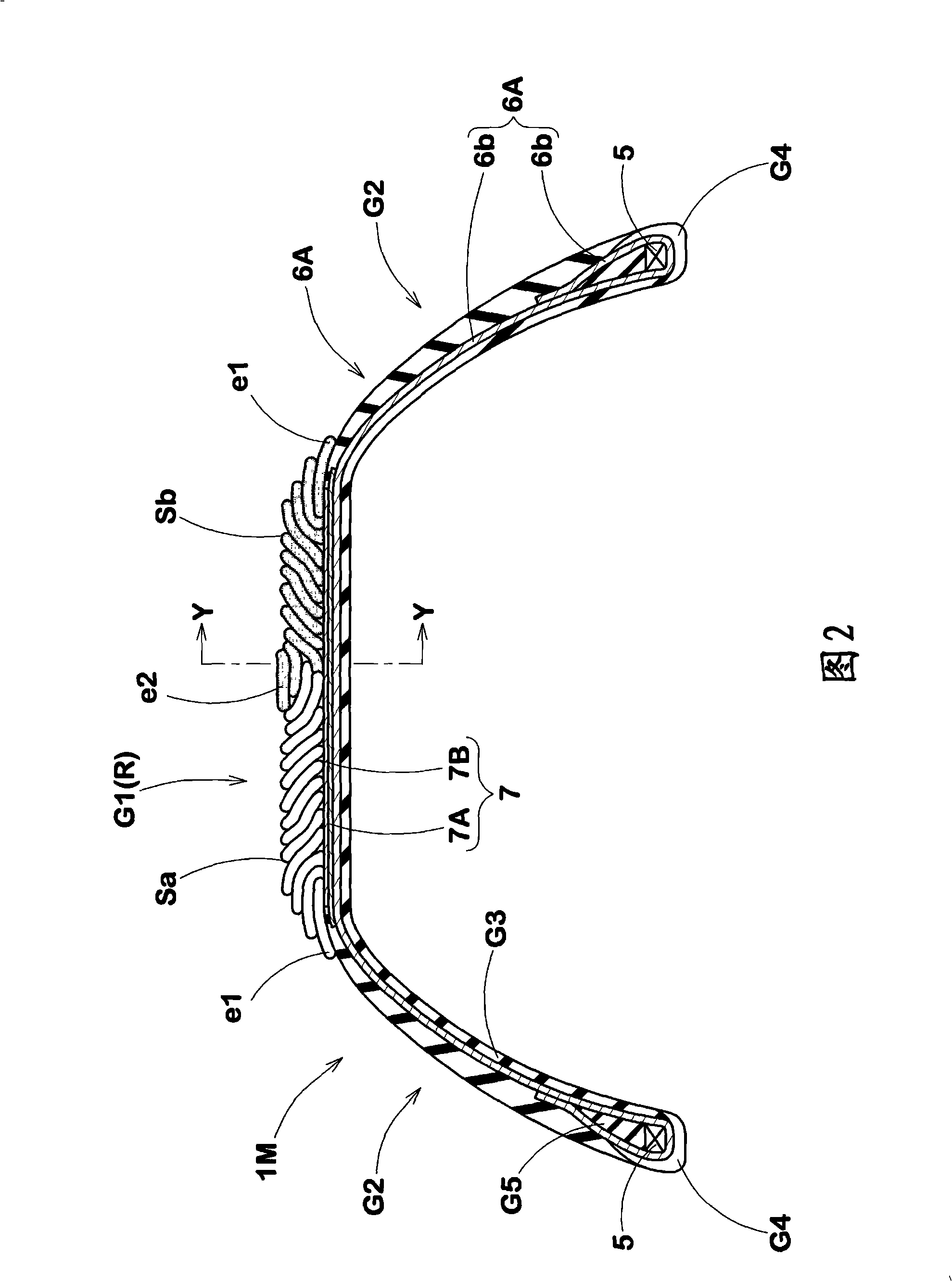

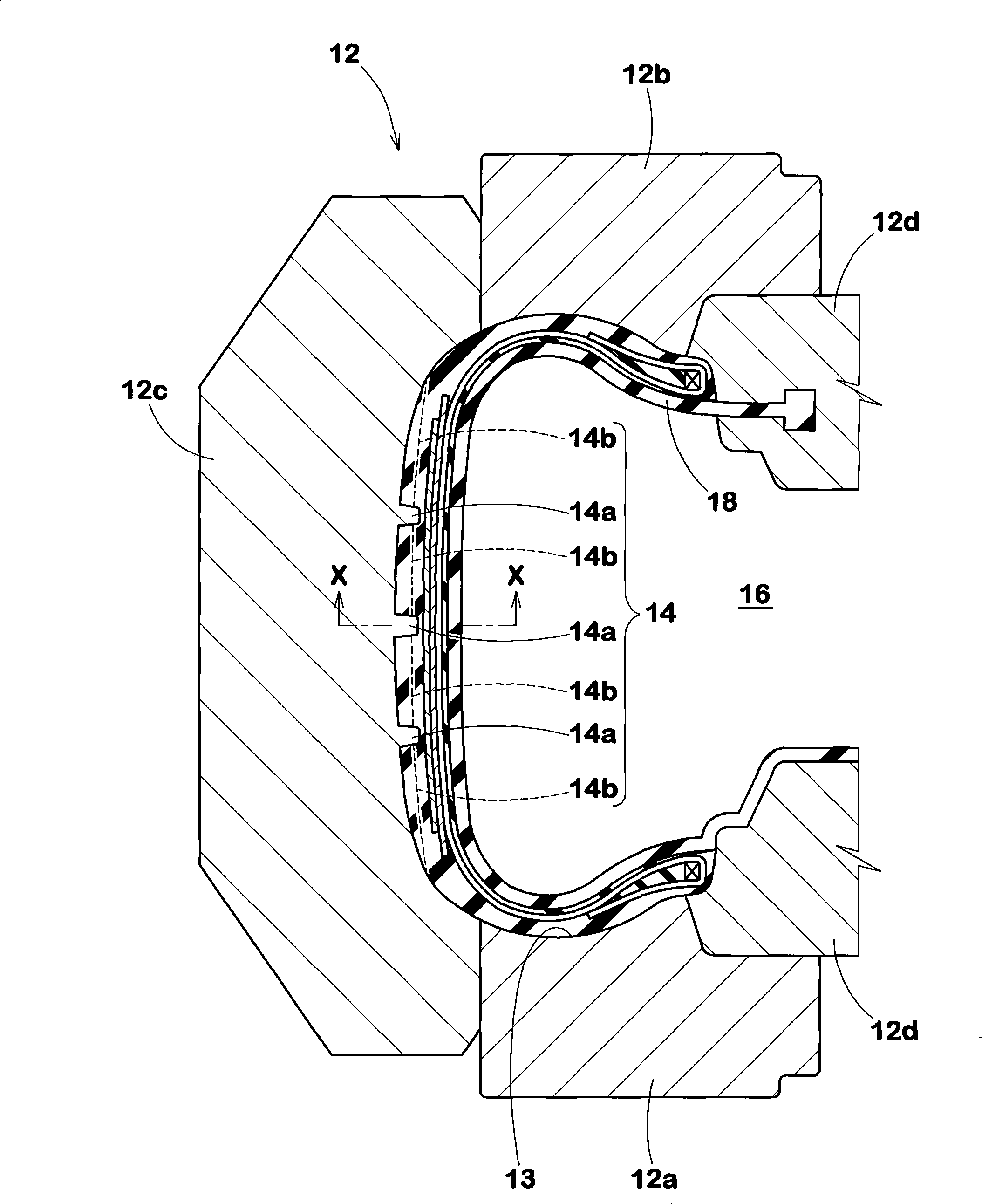

[0018] In the drawings, a pneumatic tire 1 according to the present invention includes: a tread portion 2; a pair of axially spaced bead portions 4 each having a bead core 5 therein; a pair of sidewall portions 3, which extends between the tread edge and the bead portion 4; the toroidal carcass 6, which extends between the bead portions 4 through the tread portion 2 and the sidewall portion 3; the belt layer 7, which sets In the tread portion 2, radially outside the carcass 6; and as figure 1 A number of different rubber parts G shown in.

[0019] The carcass 6 is composed of at least one ply 6A having cords arranged in a radial form at an angle ranging from 70 to 90 degrees with respect to the equator C of the tire, the carcass 6 passing between the bead portions 4 through the tread portions 2 and The sidewall portion 3 extends and turns up around the bead core 5 in each bead portion 4 from the axially inner side to the axially outer side of the tire, thereby forming a pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com