Method and apparatus for determination of coagulant injection rate in water treatment process

A technology to determine the method and coagulant, applied in the direction of flocculation/sedimentation water/sewage treatment, separation method, chemical instrument and method, etc., can solve difficult beaker test, delayed feedback of coagulant injection rate, geographical aspects, and time are not universal sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

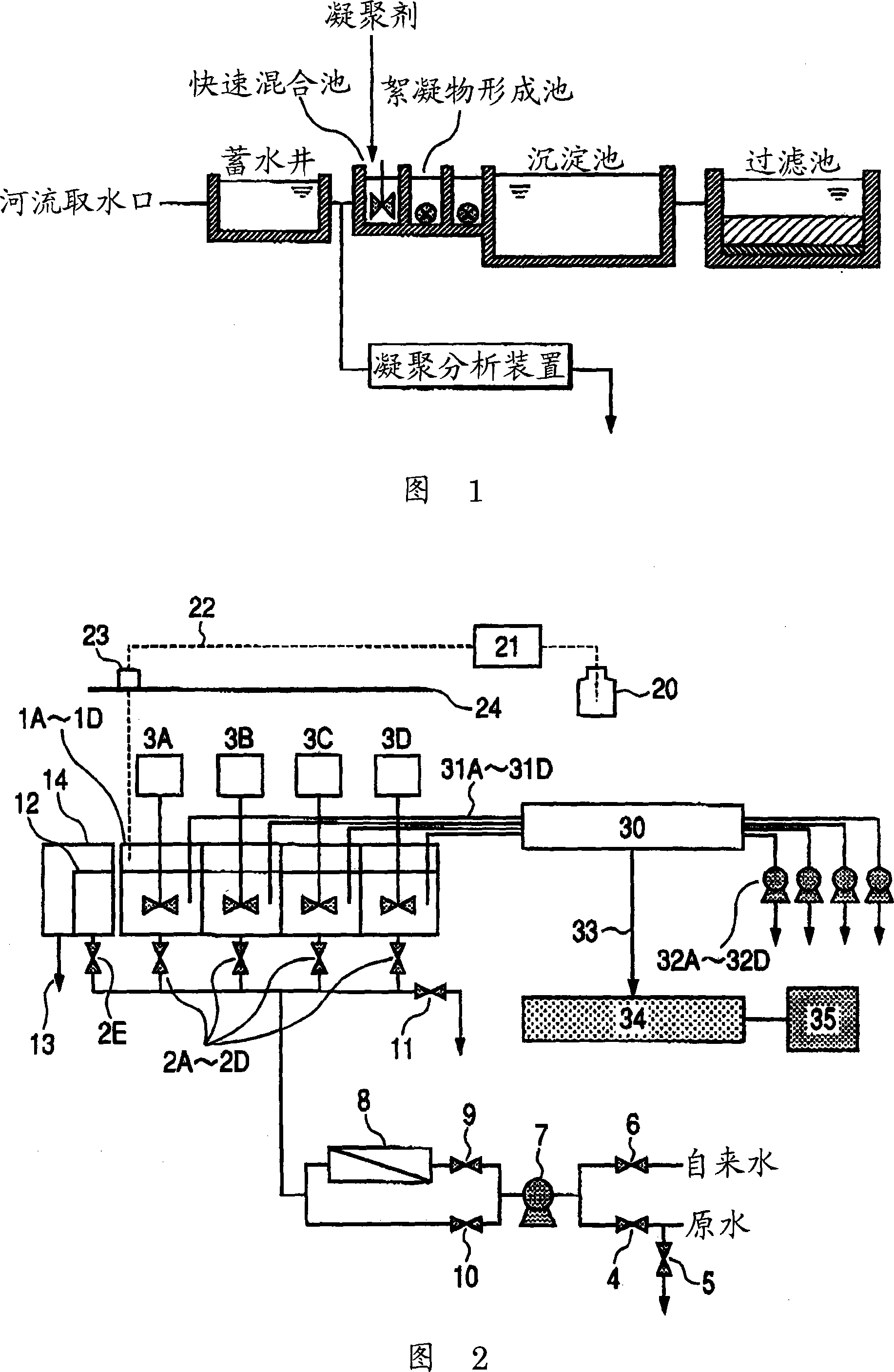

[0072] As above figure 1 As shown, the coagulation analysis device of the present invention is installed on the piping that divides the raw water from the storage well during the water purification treatment. The above water purification treatment has the following functions: the raw water taken from the river is sent to the storage well, and the In the rapid mixing tank, the injected coagulant is stirred rapidly, in the floc formation tank, the aggregates formed in the rapid mixing tank grow into flocs, in the sedimentation tank, the flocs are settled, and in the filter tank, the upper part is filtered Clarify the water. Depending on the situation, the coagulation analysis device may be connected to the raw water piping used to send water to the water quality laboratory for beaker tests and raw water quality inspections.

[0073] Here, the present invention is characterized in that an appropriate coagulant injection rate determined based on the aggregation start time measur...

Embodiment 2

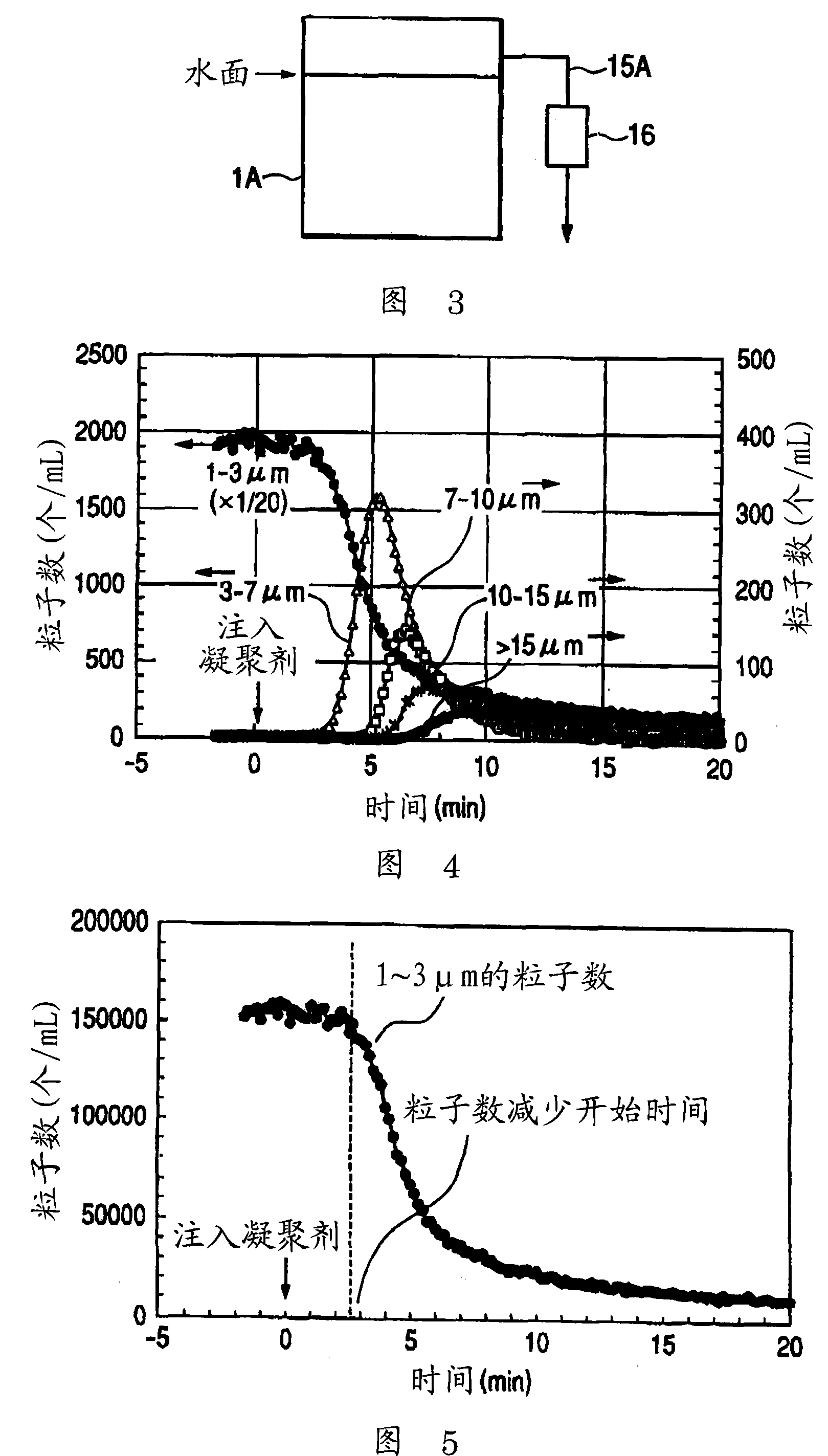

[0095] Next, based on Figures 9 to 12 , Embodiment 2 will be described. Figure 9 The coagulation analysis device of the present invention shown is composed of a test water tank 1 for holding a predetermined amount of raw water, a water supply and drainage valve 2, 2E, an agitator 3, a raw water inlet valve 4, a raw water discarding valve 5, a tap water inlet valve 6, Water supply pump 7, filter 8, filter inlet valve 9, raw water supply valve 10, drain valve 11, water level adjustment tank 14 connected to piping 13 for discharging water overflowing to overflow pipe 17, coagulant 20, Coagulant injection part 21, coagulant injection pipe 22, detector 36 for measuring the average particle size and average particle number of flocs, water intake pipe 31, water intake pump 32, for analyzing and controlling the electrical signal 33 from the detector The program device 34 of the equipment, the POD 35 for displaying the measurement results and the setting conditions of the input devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com