Split type chain sprocket splicing structure

A split-type, sprocket technology, used in belts/chains/gears, portable lifting devices, components with teeth, etc., can solve the problems of weakened chain shaft strength, cumbersome installation, short service life, etc., to achieve stable performance, Easy installation and disassembly, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

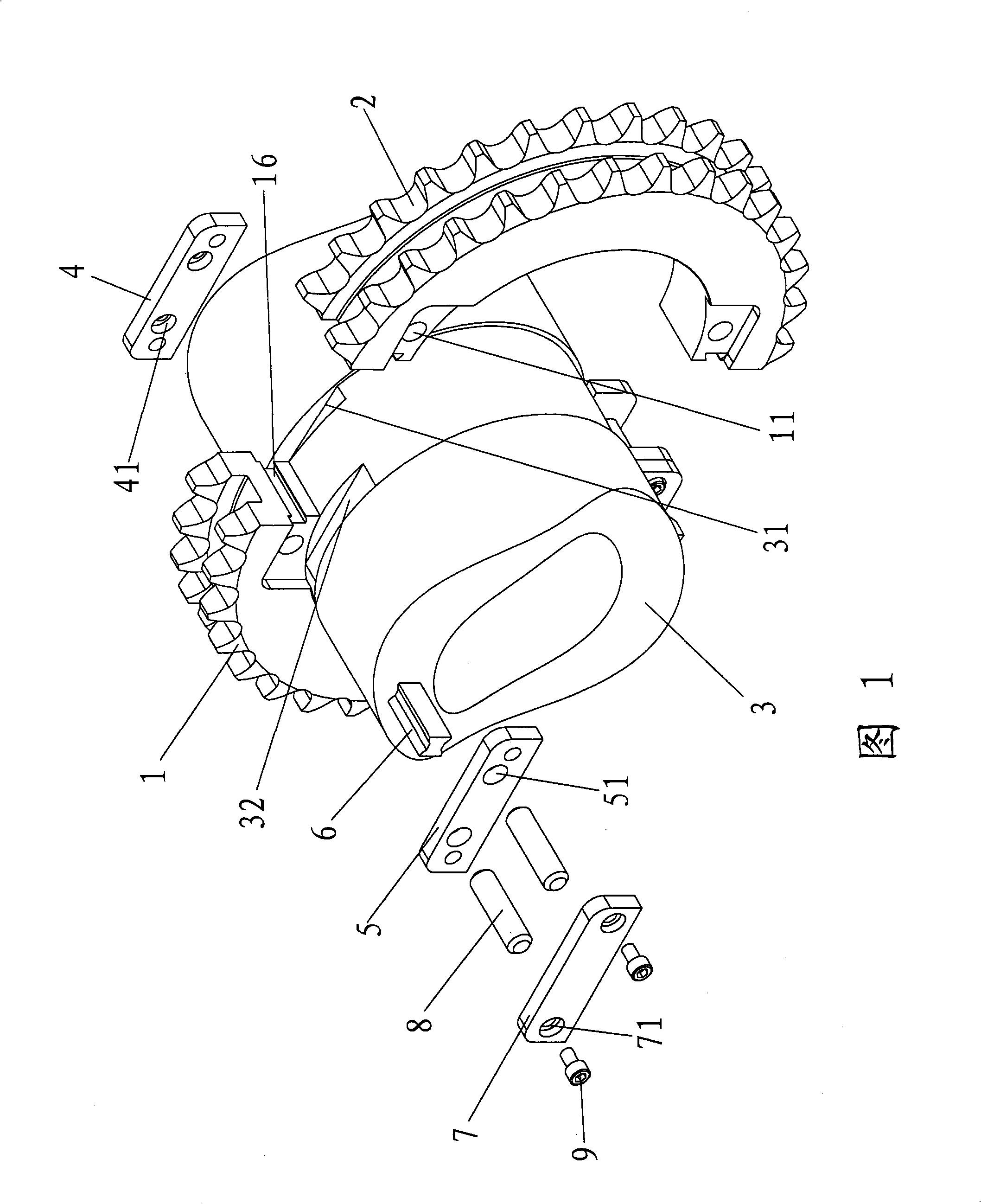

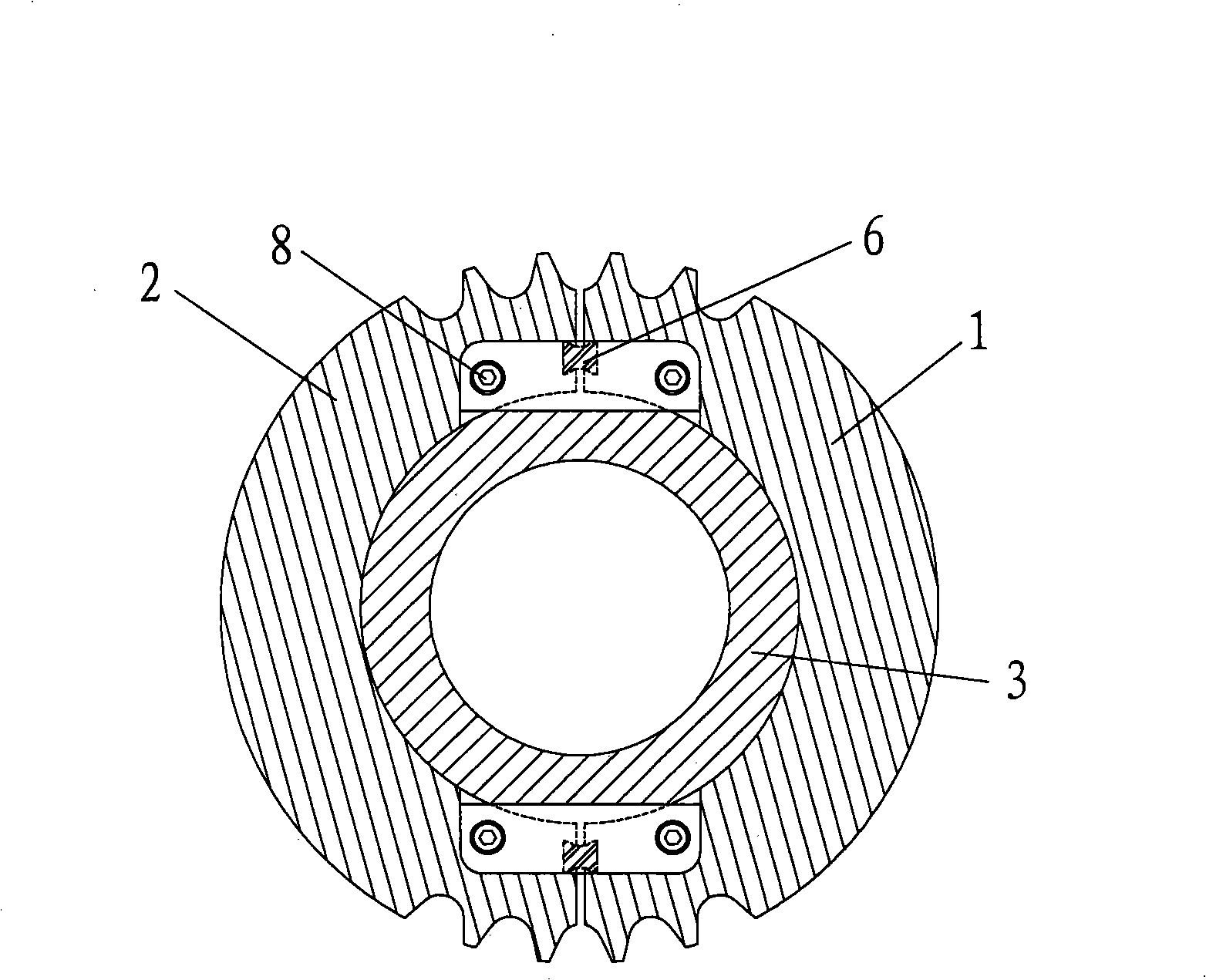

[0020] Referring to Fig. 1, a splicing splicing structure of a split type sprocket includes a sprocket and a sprocket 3 used in conjunction with the sprocket. The sprocket includes two spliced half-wheels 1 and 2, wherein half-wheel 1 The fastening connection structures for fixedly connecting the sprocket wheel and the chain shaft 3 are respectively provided at the two splicing places between the half wheel 2 and the half wheel 2. As shown in Figure 1, there is a fastening connection structure at the upper and lower joints.

[0021] The fastening connection structure includes: a first groove 31 and a second groove 32 are respectively provided on both sides of the chain shaft 3 where the two half-wheels are spliced along the circumferential direction, and the first groove 31 is clamped in the first groove 31. A pressing plate 4, a second pressing plate 5 clamped in the second groove 32, the first pressing plate 4, the two half-wheels 1 or 2 and the second pressing plate 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com