Material high-temperature creep life predication method

A high-temperature creep and life-span technology, which is applied in the direction of analyzing materials, measuring devices, and special data processing applications, to achieve the effects of convenient creep design, reducing the amount of high-temperature tests, and realizing stepless expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 , High temperature creep life accelerated test

[0059] 1.1. Short-term stress relaxation test

[0060] The test is a uniaxial tensile stress relaxation test at 600°C. The test piece is a forged bar with a standard structure and size of 100mm in length and 10mm in diameter. The test time is set according to the design terminal stress of 160MPa and is determined naturally after the test. The test parameters are shown in Table 1 below.

[0061] Table 1. Stress relaxation test parameters of Cr10NiMoW2VNbN alloy

[0062] Initial stress MPa 300 325 350 375 400 450 Test time h 27 45 71 106 152 211

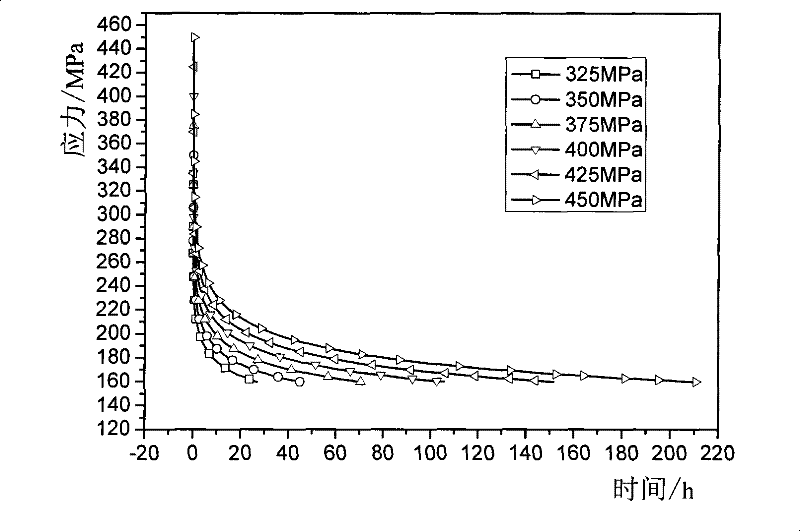

[0063] Obtain the time-stress curve according to the result of table 1, the result is as follows figure 1 shown.

[0064] 1.2. Construction of relaxation rate-stress curve

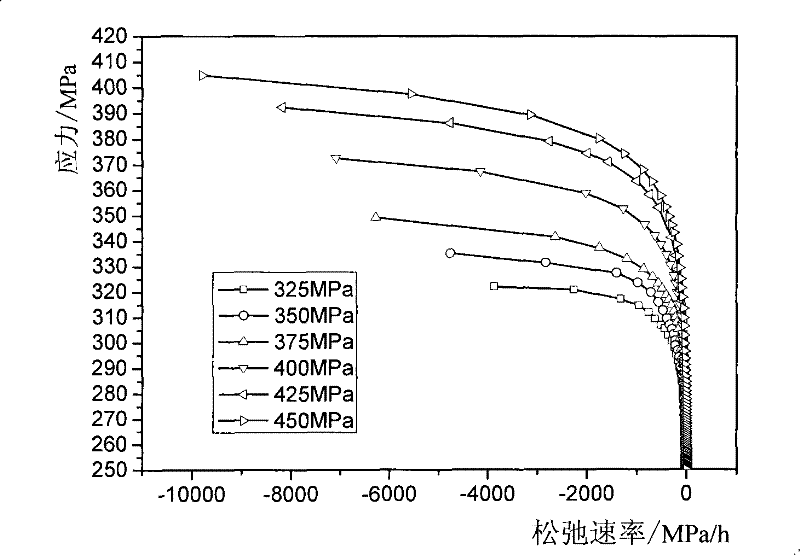

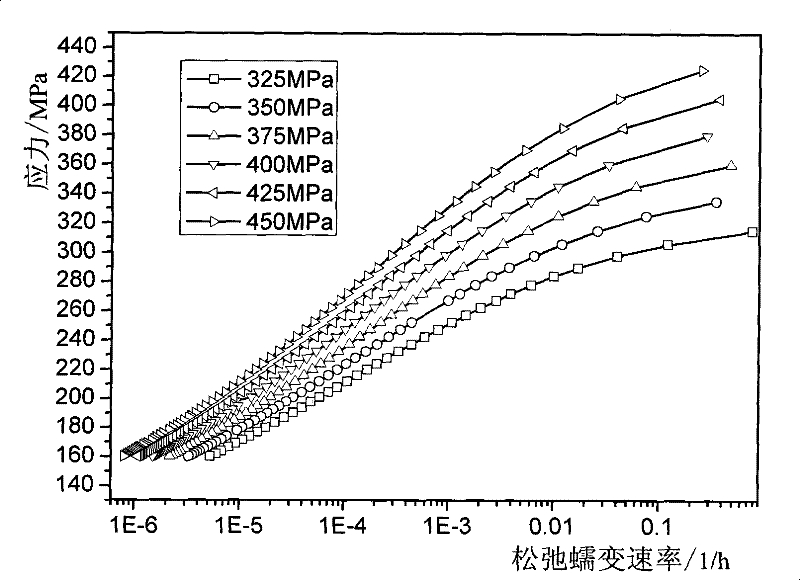

[0065] right figure 1 Numerically differentiating the relaxation curve shown, we get figure 2 The relaxation rate-stress...

Embodiment 2

[0082] Example 2 , Creep test verification

[0083] In order to verify the reliability of the above method, the actual creep data and the conversion results of the short-term relaxation test were plotted together in the Figure 4 , for a comparison. Creep test data are taken from literature Yao H T, Shen S F, Xuan F Z, et al. Experimental Investigations on Mechanical Properties of a High Cr Ferritic Steel for USC Steam turbineRotor[A], Challenges of Power Engineering and Environment[C].Proceedings of the international conference on power engineering 2007. October 23-27, 2007, Hangzhou China, p: 1066-1070.

[0084] From Figure 4 It can be seen that the conversion results are in good agreement with the actual creep data; in addition, the converted material constant K=6.34×10 -33 , n=11.238 and the corresponding material constant 6.67×10 obtained according to the creep test data -33 , 11.18 are very close, so the accelerated creep test method is reliable and can be used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com