Yarn reeling machine

A yarn coiling machine and frame technology, which is applied in the field of yarn coiling machines, can solve problems such as easy shaking of the contact roller, uneven contact pressure of the package, and easy shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

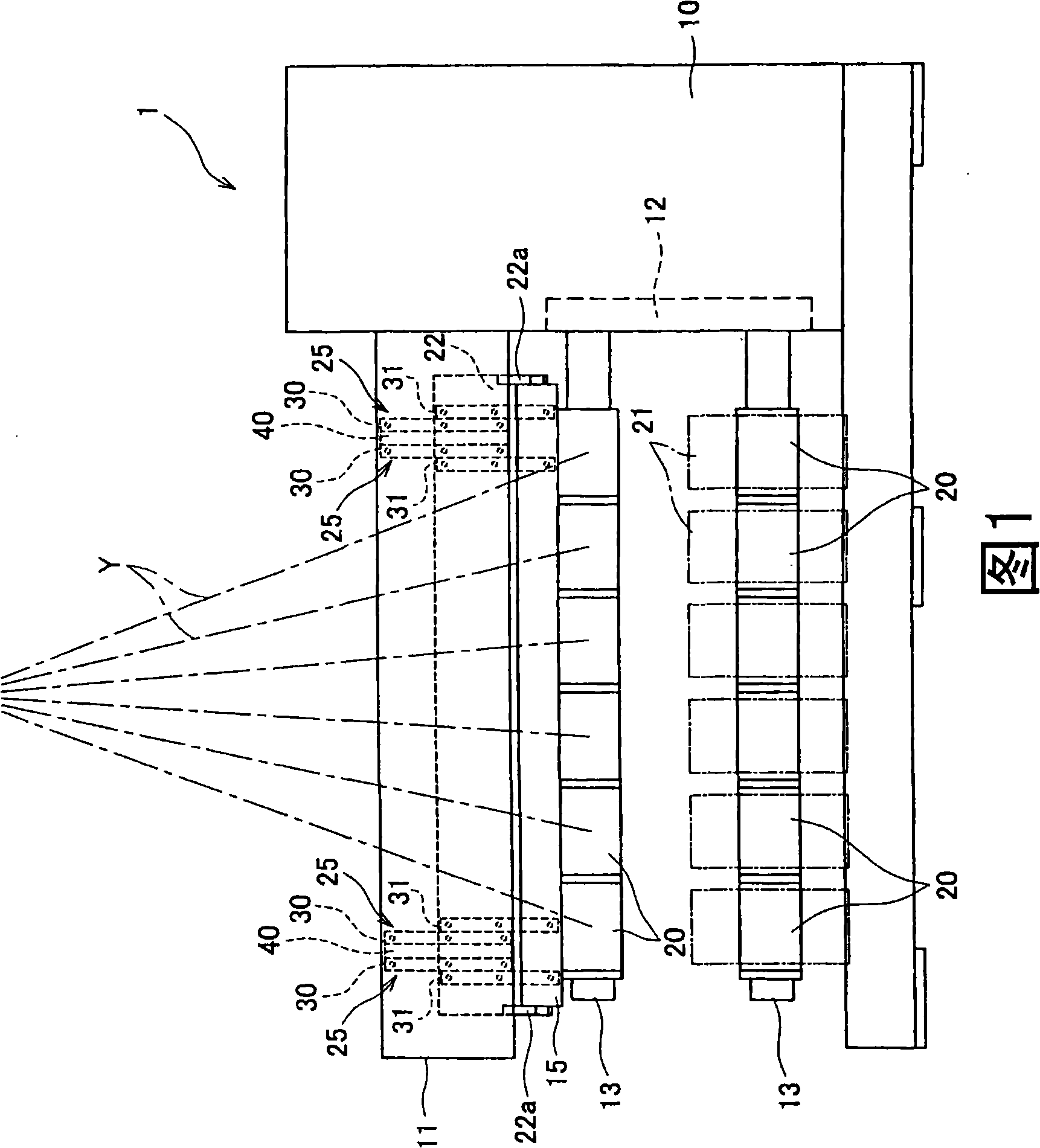

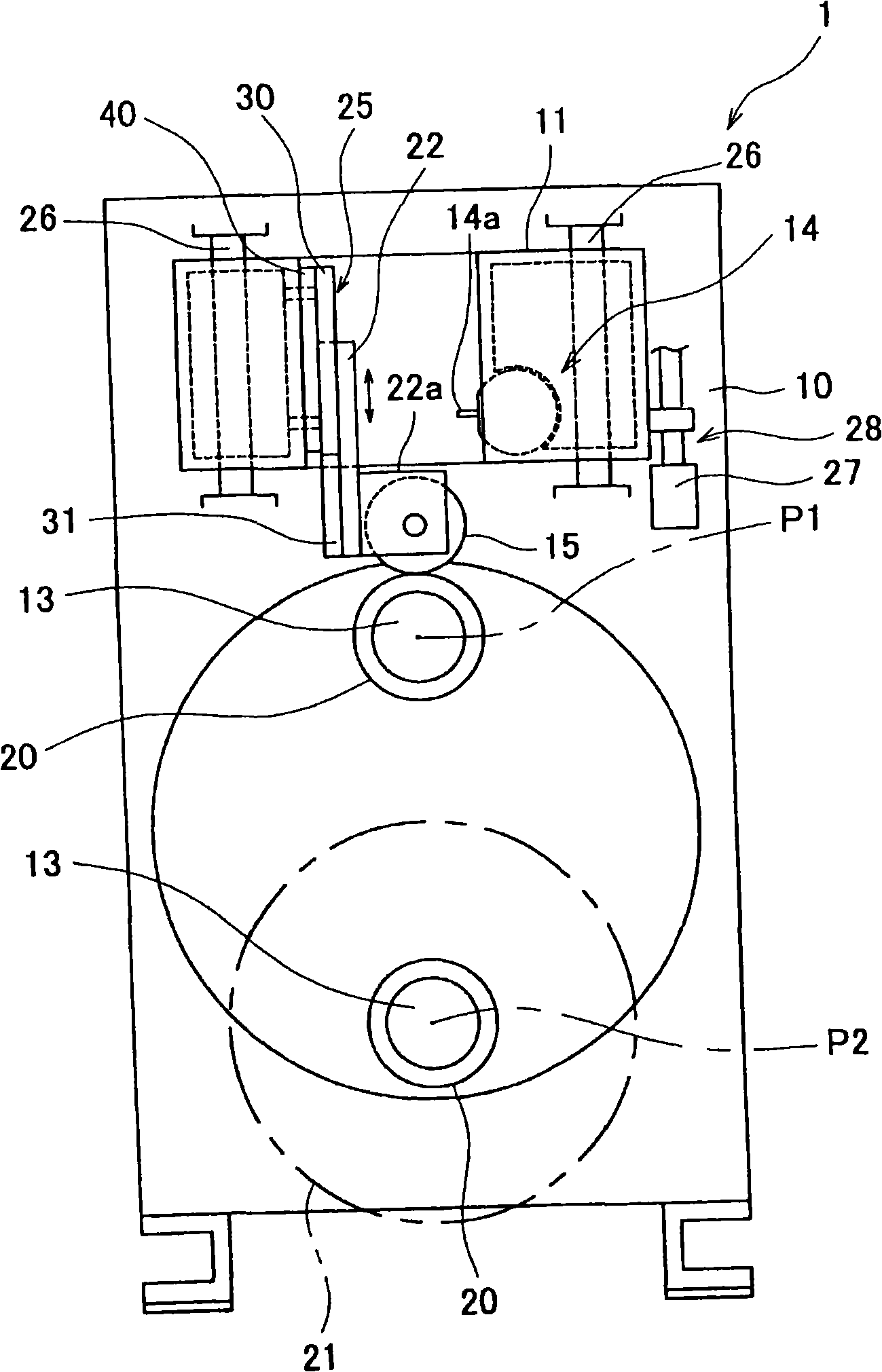

[0018] Embodiments of the present invention will be described. As shown in FIG. 1 , a plurality of (six in this embodiment) yarns Y are continuously supplied to the yarn winding machine 1 from a spinning machine not shown in the figure. The yarn winding machine 1 is configured to wind a plurality of yarns Y supplied from a spinning machine around a plurality of bobbins 20 to form a plurality of packages 21 .

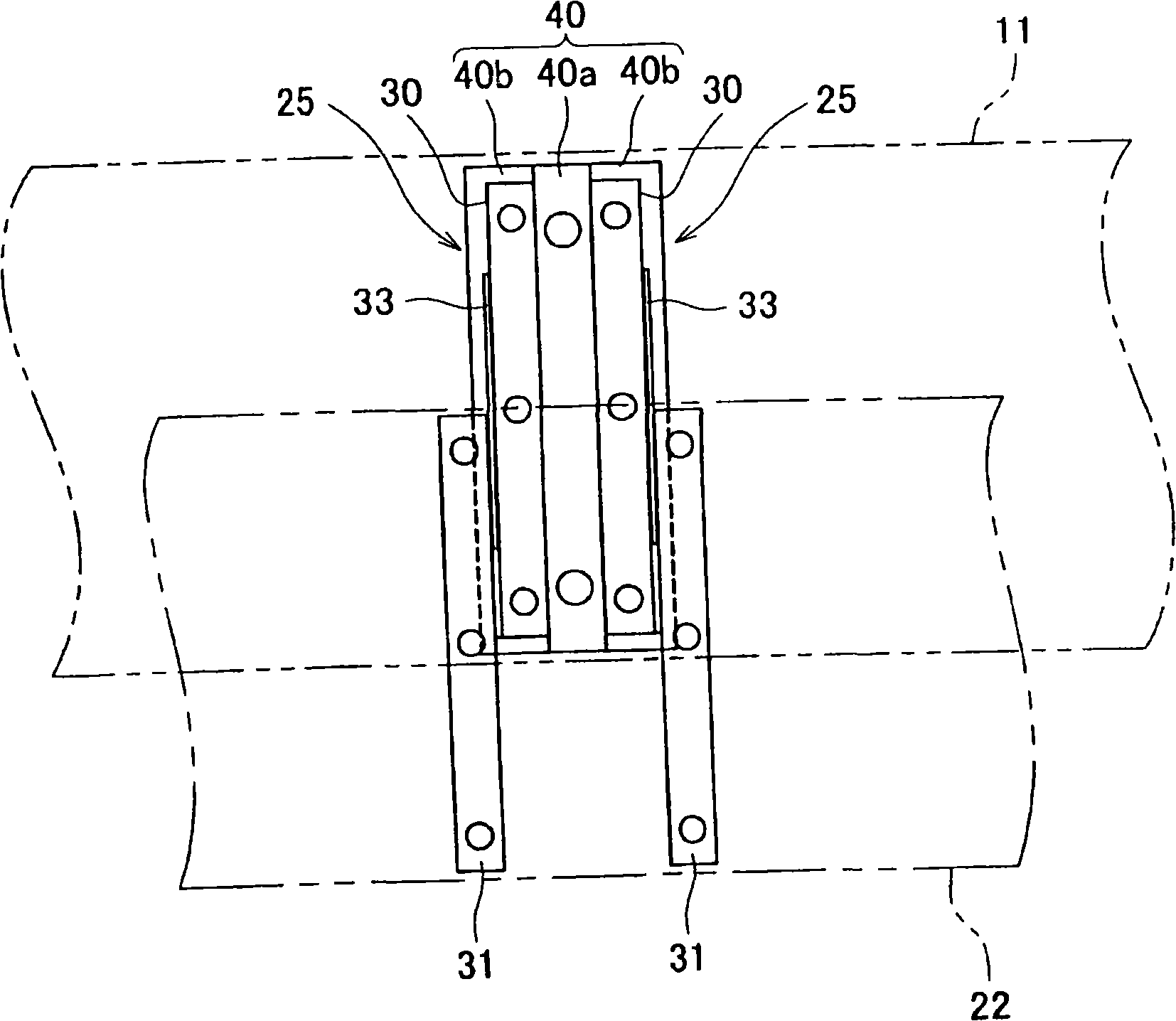

[0019] Figure 1 and figure 2 As shown, the yarn winding machine 1 includes a main frame 10, a lifting frame 11, a disc-shaped turntable 12, two bobbin holders 13, a traverse device 14, a touch roller 15, and the like. The lifting frame 11 is provided on the main body frame 10 so as to be movable (liftable) in the vertical direction. The turntable 12 is rotatably provided on the main frame 10 . The bobbin rack 13 is supported on the main body frame 10 through the turntable 12, and a plurality of bobbin tubes 20 are mounted thereon. The traversing device 14 is a device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com