Centrifugal blower with backward inclined blade wheel

A backward vane and vane wheel technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. Saving energy is not economical and other issues, to achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

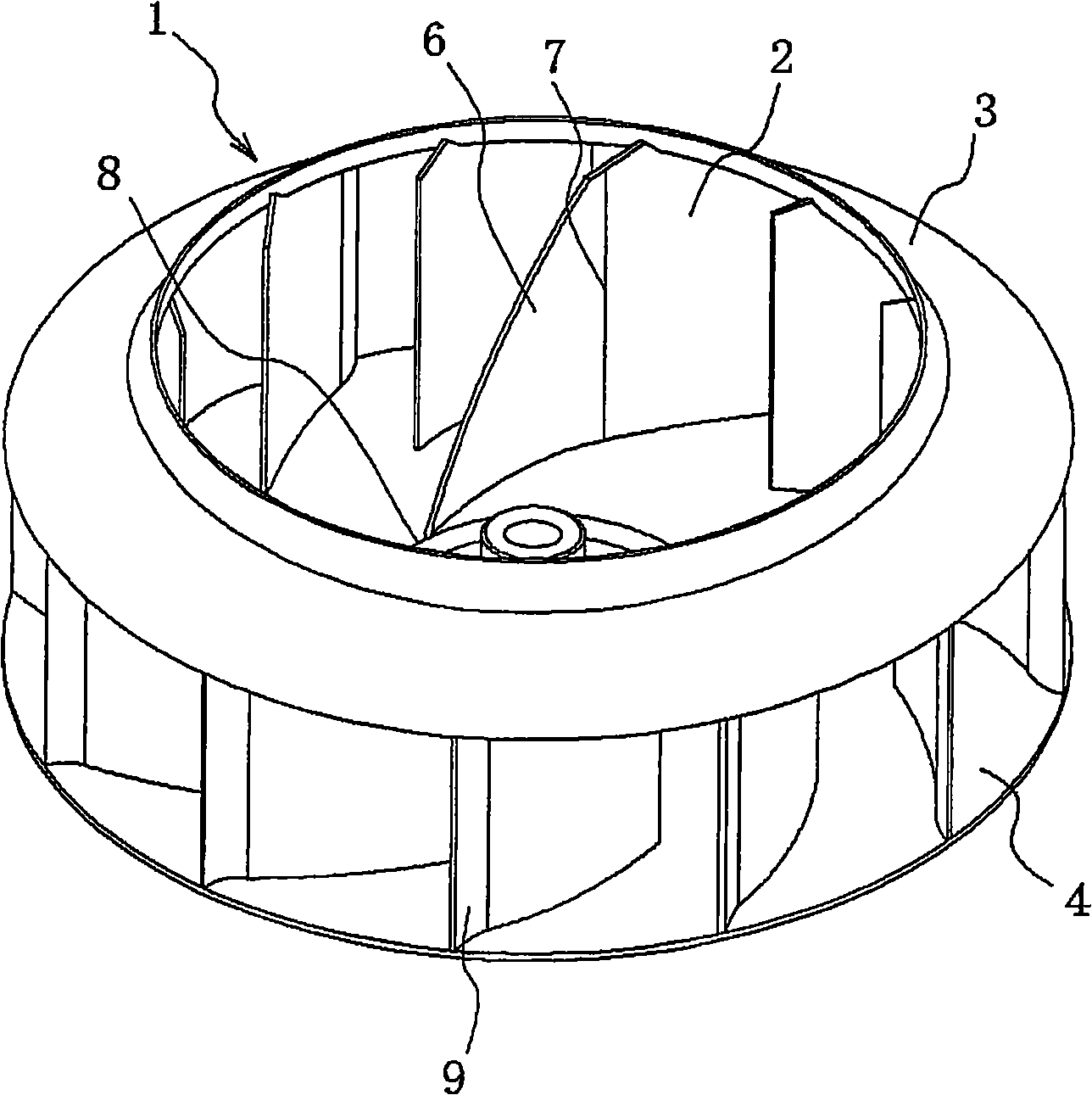

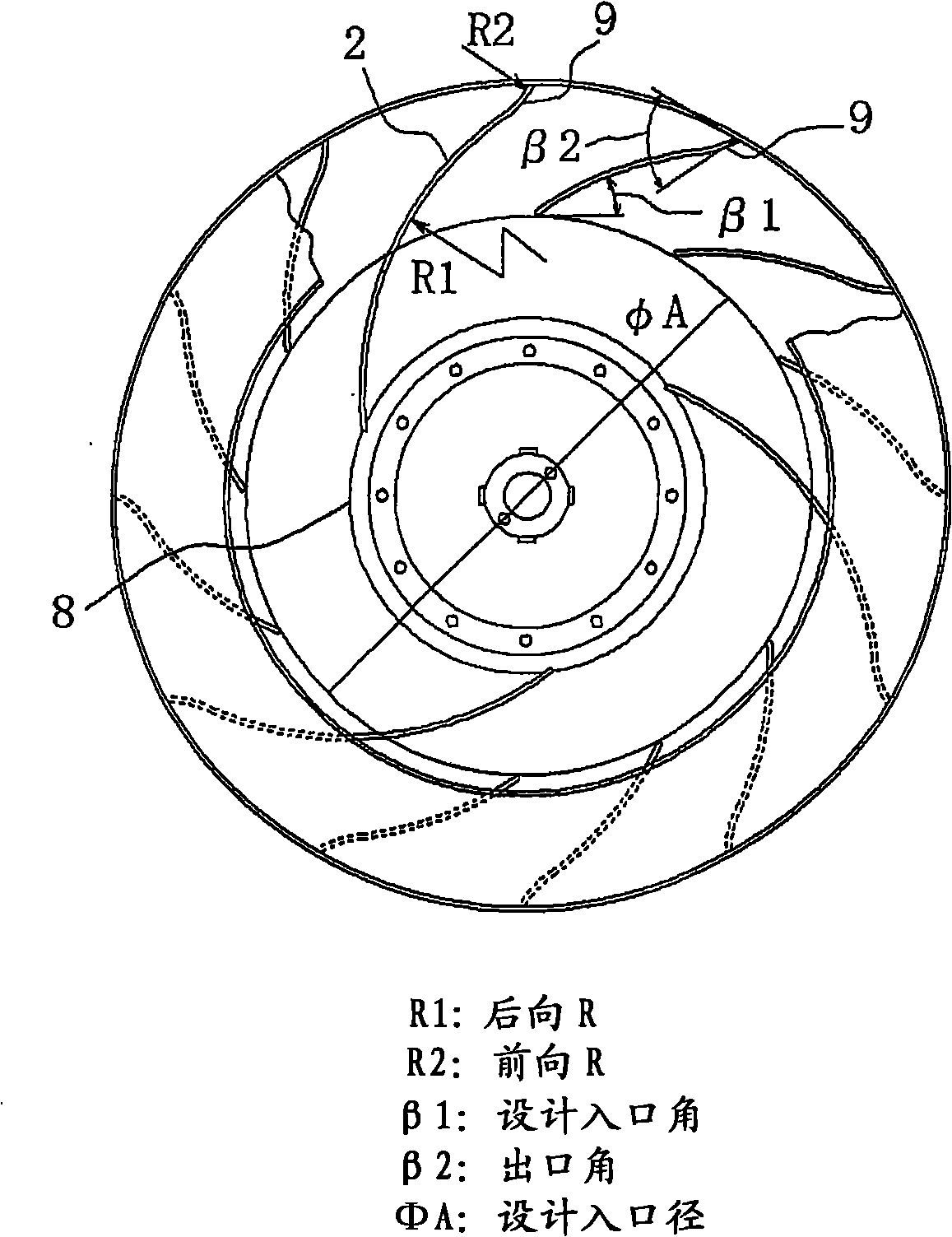

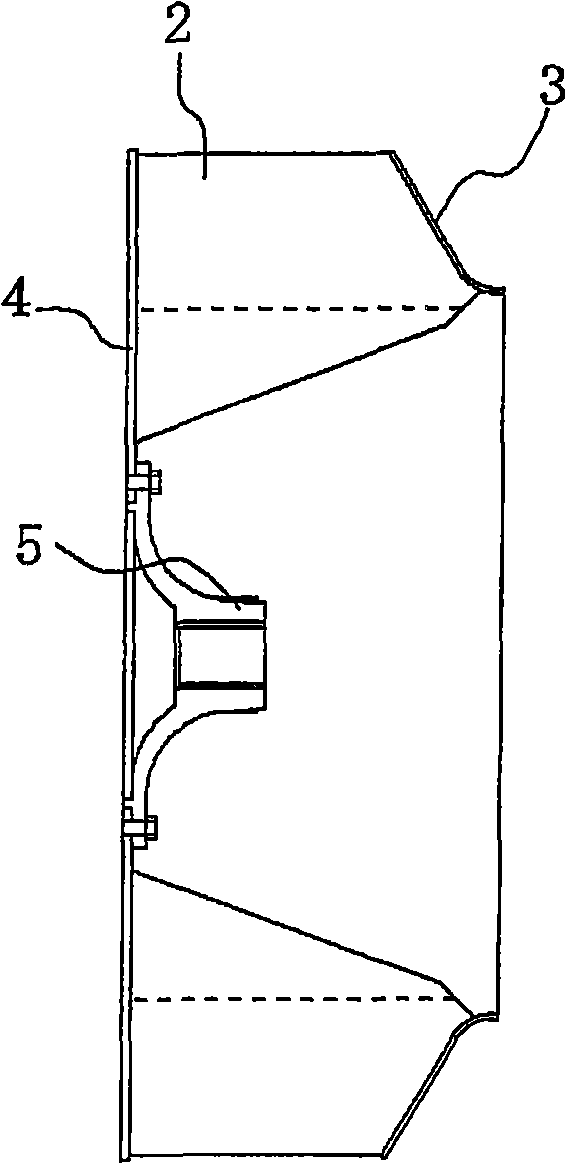

[0020] Fig. 1 shows a schematic diagram of an embodiment of the blade wheel of the centrifugal blower of the present invention, Fig. 2 is a plan view, and Fig. 3 is a cross-sectional view. The backward vane wheel 1 is composed of a vane plate 2, a shroud 3, an impeller disk 4, and an impeller shaft 5 forming vane pieces. The blade plate 2 is arranged at equal intervals around the circumference between the shroud 3 of the blade wheel 1 and the impeller disk 4, and every three of the blade plates 2 group, the slightly triangular extension 6 is formed from the blade The front edge portion 7 of the plate 2 is curved forward in a streamline shape along the direction of rotation, and is provided so that the front end portion reaches the inner edge portion 8 of the blade wheel 1.

[0021] The shape of the curved portion of the blade plate 2 having the extension 6 is shown in FIG. 2 as being curved backward (curvature R1) with respect to the rotation direction of the blade wheel. The blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com