Breathing machine and its low differential pressure type flow quantity detection mechanism

A flow detection and differential pressure technology, applied in the field of low differential pressure flow detection mechanisms, can solve the problems of narrow range, influence of measurement performance, and high installation conditions, to achieve accurate measurement, reduce breathing work, and reduce expiratory resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. In the drawings, the same components are denoted by the same reference numerals.

[0017] The technical scheme adopted in the present invention:

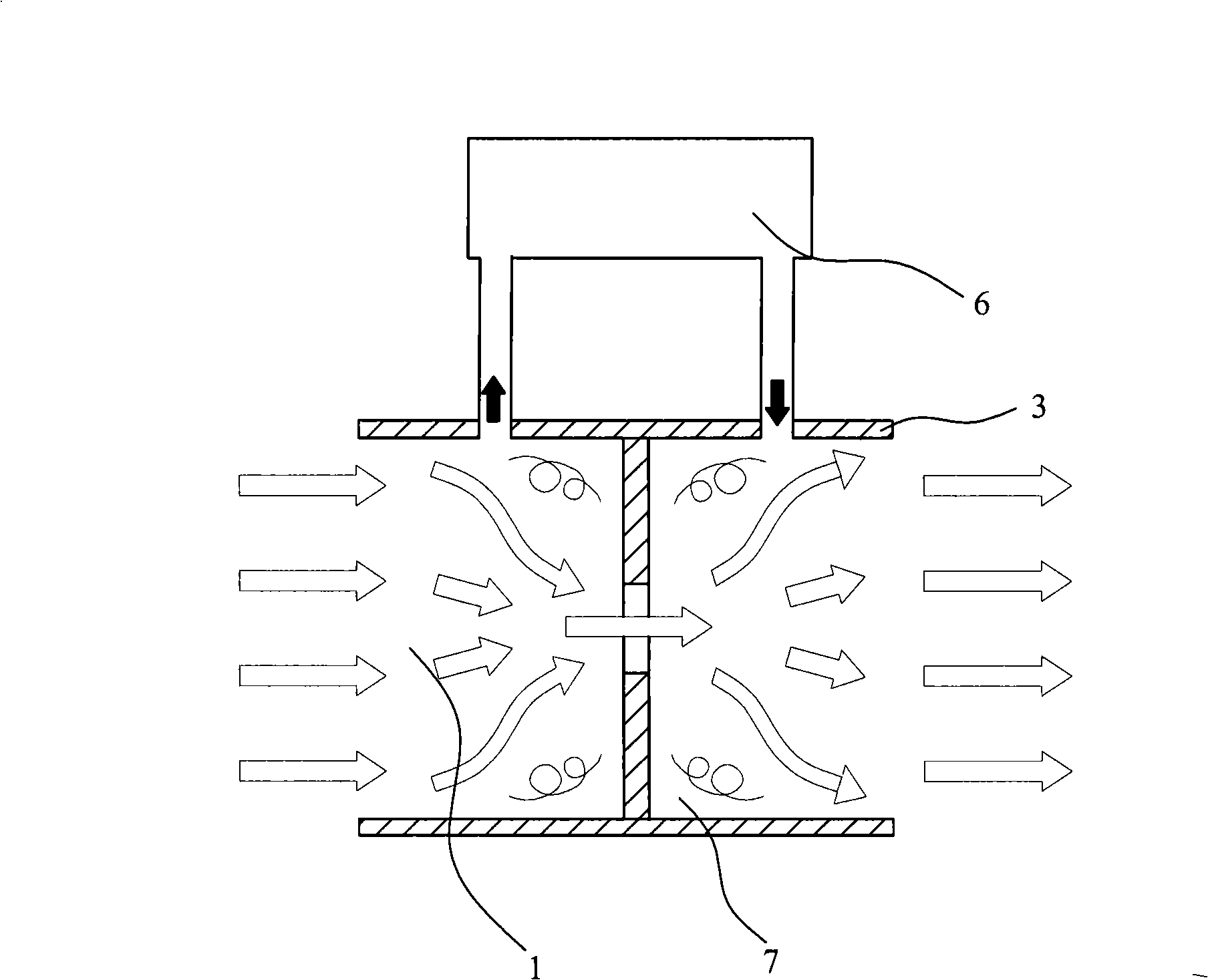

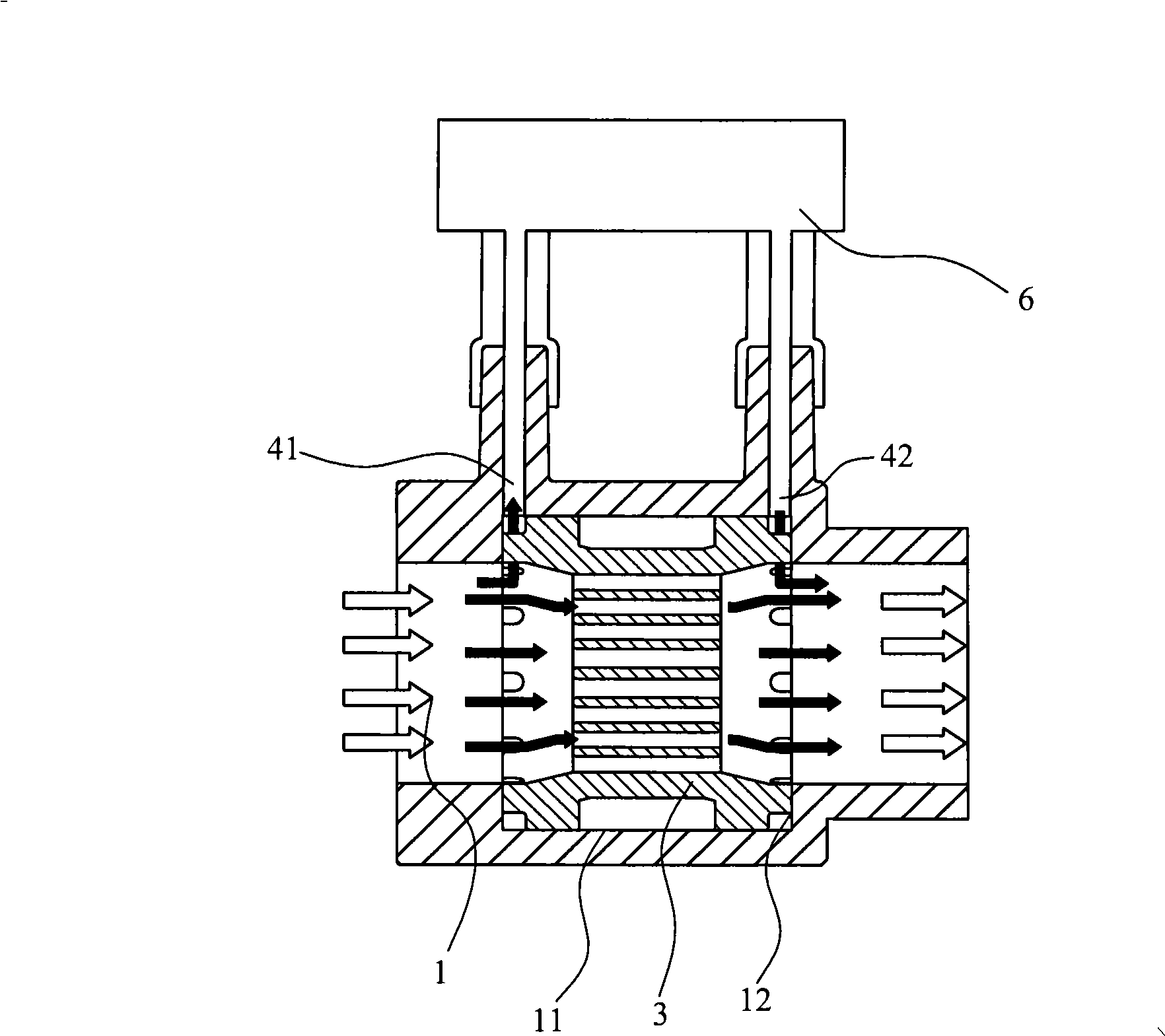

[0018] Such as figure 2 As shown, a specially designed independent throttling device 3 is placed in a section of the circular main gas path 1. The throttling device 3 is composed of several rings nested together. The main gas path 1 includes two sampling ports 41 and 42, the sampling port is respectively connected to the inlet and outlet of the metering device 6 that adopts a high-sensitivity mass flow sensor. The main air circuit 1 also includes a limiting end surface 12 , the throttling device 3 is installed in cooperation with the limiting end 12 , and the sampling ports 41 and 42 are just above the two ends of the throttling device 3 .

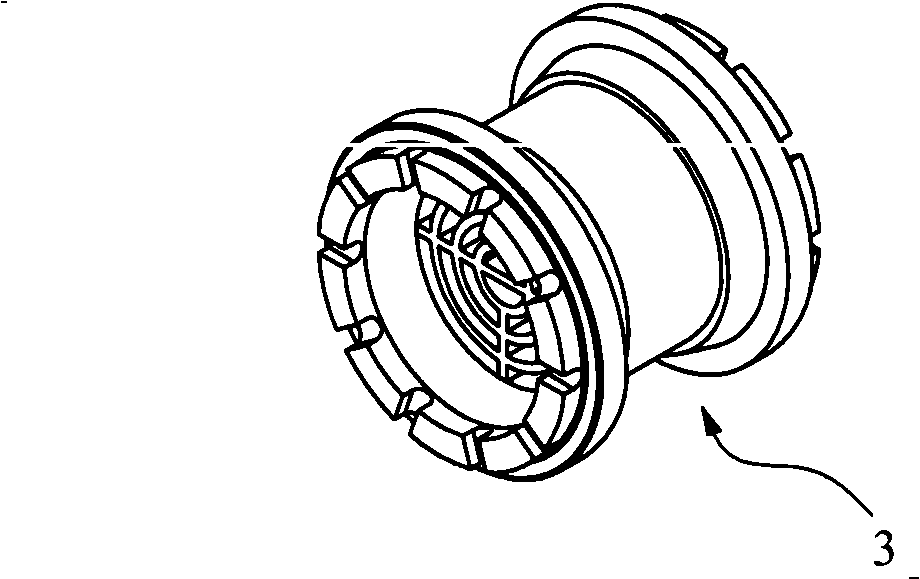

[0019] What Fig. 3 shows is described special throttling device 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com