Method for recycling an image-forming member

A technology of imaging components and recycling, applied in the fields of electrical recording technology using charge graphics, equipment for using electrical recording technology using charge graphics, and electrical recording, can solve problems such as difficult to obtain performance elastic body parts, and achieve recovery performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

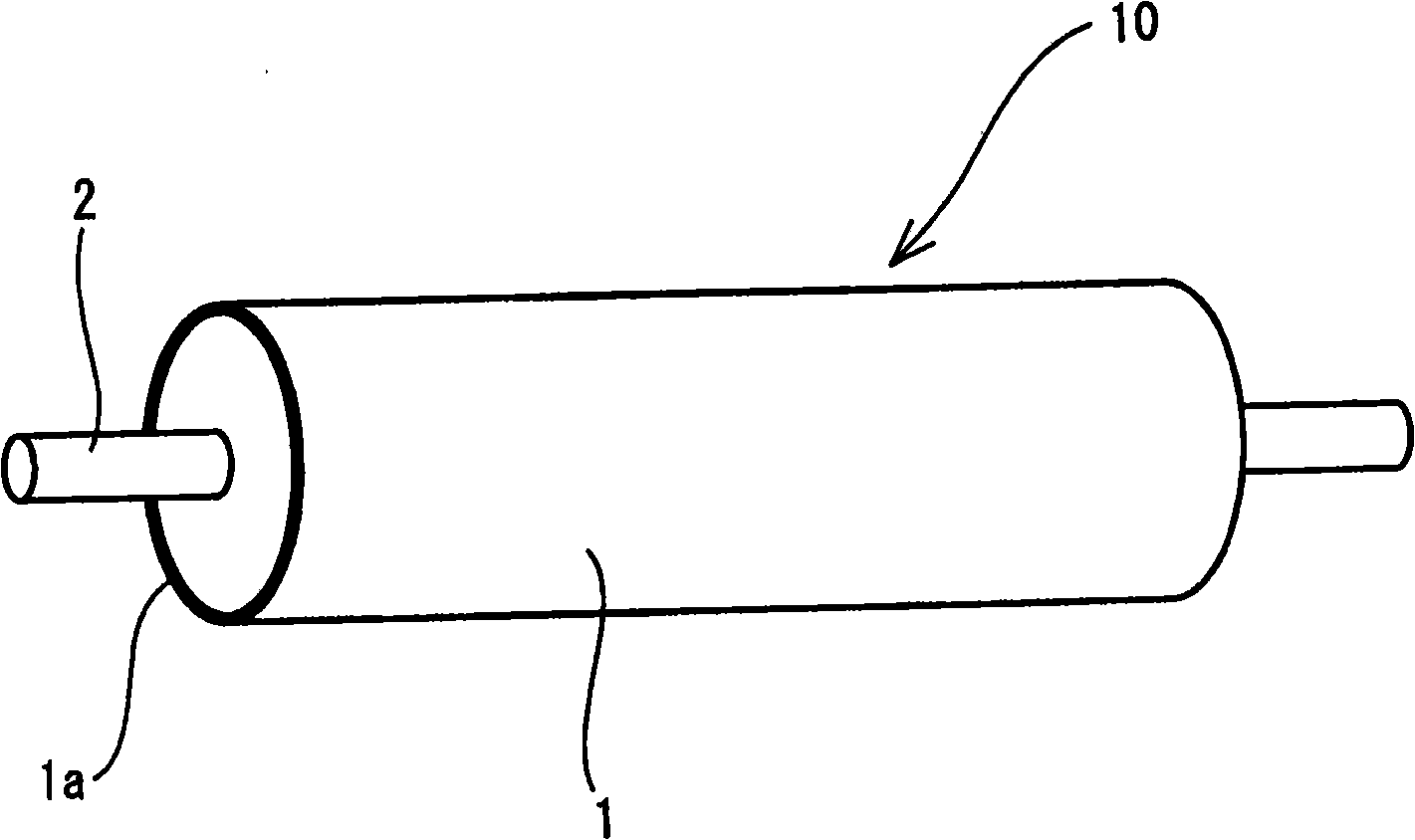

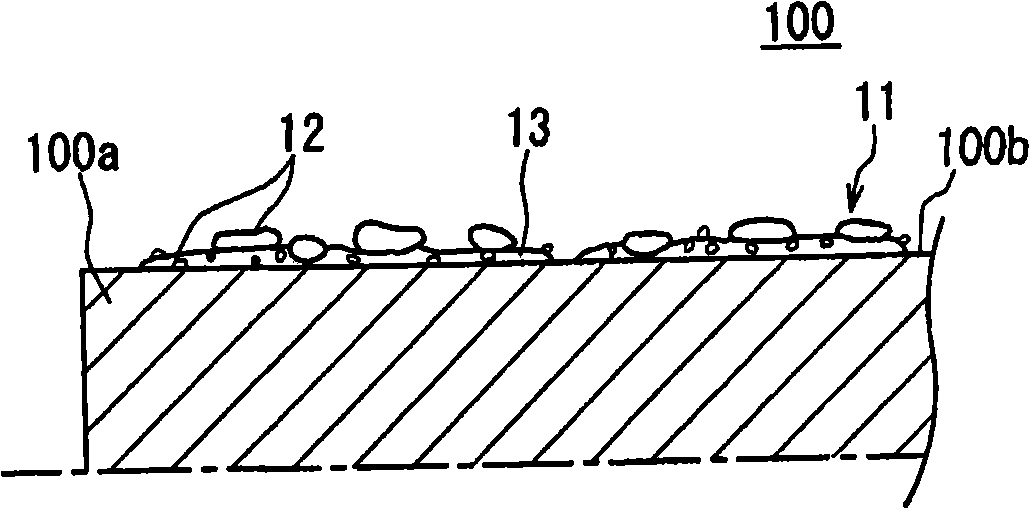

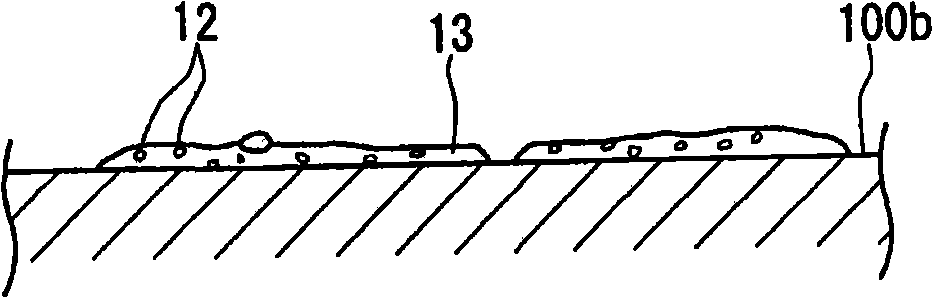

[0173] After washing the surface of the roller with dirt attached thereto with water and air-drying it, the roller was irradiated with ultraviolet rays (wavelength: 184.9 nm and 253.7 nm) at intervals of 90° along its circumferential direction by an ultraviolet irradiation lamp 5 cm apart from the roller 5 minute. The roll was rotated 4 times at 90° to irradiate its entire outer surface (360°) in one pass. The surface of the developing roller was irradiated with ultraviolet rays at intervals of 90° for 5 minutes. The total irradiation time period is then 20 minutes.

Embodiment 2

[0175] After blowing air on the surface of the developing roller on which the dirt was attached, the surface was irradiated with ultraviolet rays for the first time. The surface of the roller is then washed with water. After the surface of the roll is air-dried, its surface is irradiated with ultraviolet rays for the second time.

[0176] The conditions of the first irradiation and the second irradiation of ultraviolet rays and the conditions of washing the surface of the roller with water were similar to those used in Example 1.

Embodiment 3

[0178] After air was blown on the surface of the roller with dirt attached thereto, the surface thereof was irradiated with ultraviolet rays. After washing the surface of the roller with water, it is air-dried.

[0179] The irradiation conditions of ultraviolet rays and the conditions of washing the surface of the roller with water were similar to those used in Example 1.

[0180] ·Reference example

[0181] A new rubber roller on which no dirt was attached was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com