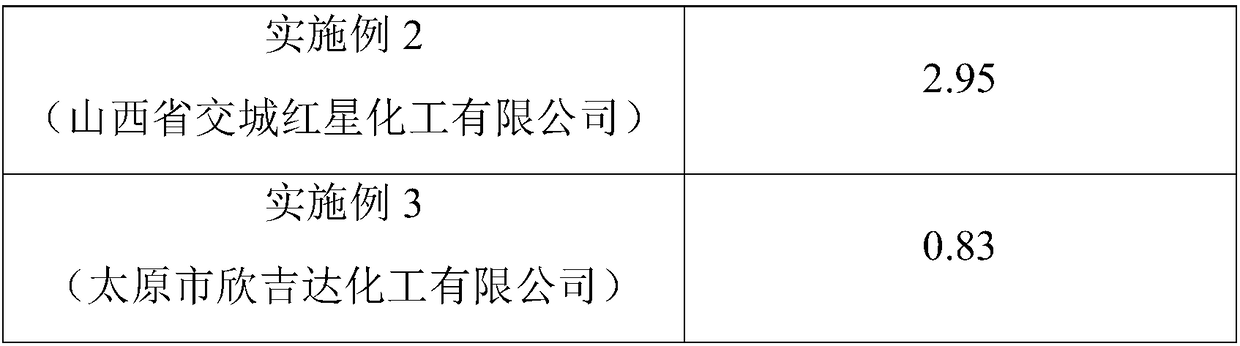

Patents

Literature

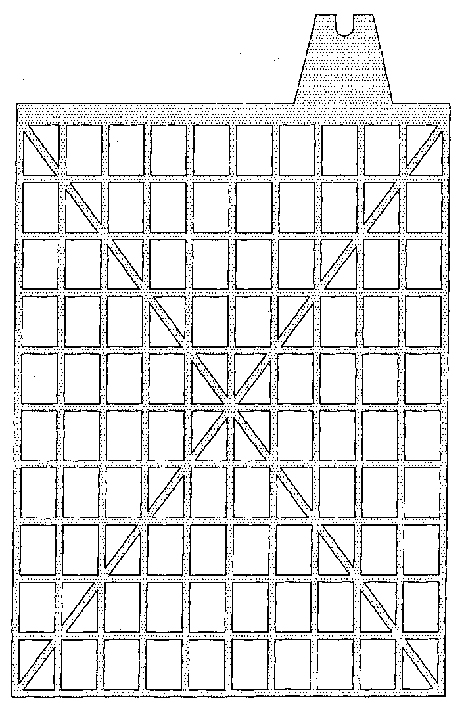

46results about How to "Change surface state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical granulation processing method for quartz surface

A method for chemically and roughly treating a quartz surface overcomes the defects of the prior art in which the treatment to the quartz surface easily leads to damage and influences the size accuracy of the quartz product. The method is as below: at a normal temperature and a normal pressure, immersing a quartz product into a container filled with a treating fluid so as to undergo reaction after the surface of the quartz product is polished, taking out the quartz product after two-hour reaction, and immersing the quartz product into the treating fluid again so as to repeat the preceding reaction till the roughness Ra of the surface of the quartz product is equal to 1.5 micrometers to 4.5 micrometers after attachments on the surface of the quartz product is eliminated with deionized water. The treatment process has reasonable design, involves simple devices and is easy to be operated, and the obtained quartz product has uniform surface roughness which is free from the influence of the shape. During the participation in the CVD reaction, the crazing and the shedding of a deposited film on the quartz surface is effectively reduced so as to reduce the possibility of pollution to the reaction cavity, to remarkably improve the finished product rate and the production efficiency, and then further to prolong the service life of the quartz product, save time, reduce consumption and reduce production cost.

Owner:SHENYANG HANKE SEMICON MATERIALS

Method for raising efficiency of battery prepared from dye sensitized TiO2 Nano crystal

InactiveCN1540772AChange surface stateIncrease the ratio of chemical bonding adsorptionLight-sensitive devicesFinal product manufactureChemical adsorptionOpto electronic

TiO2 Nano grains with size less than and equal to 2nm are formed on surface of TiO2 Nano grain with size larger than 10 nm through chemical deposition method, thus surface state of TiO2 Nano grain is changed. Number of unsaturated titanium atoms is much more than number of TiO2 Nano grain with large size. The said changed surface state of TiO2 Nano grain possesses better characteristic of chemical adsorption so as to increase proportion of chemical adsorption of dye molecule on surface of Nano crystal. Result is to raise opto-electronic conversion efficiency of battery of TiO2 Nano crystal.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for performing surface modification treatment to carbon fiber through electrochemical polymerization and carbon fiber composite material

The invention provides a method for performing surface modification treatment to carbon fiber through electrochemical polymerization. The method comprises the following steps: with the carbon fiber asan anode and a graphite plate as a cathode, adding graphene oxide and a polymeric monomer, which is selected from diacetone acrylamide, acrylic acid and phenol, into an electrolyte solution, performing an electrochemical polymerization reaction on the surface of the carbon fiber under the action of current, then taking out the carbon fiber, washing, and then drying. By the method, with the graphene oxide as a bonding point between the monomer and the carbon fiber, monomer polymerization is performed on the surface of the carbon fiber to form a three-dimensional grid structure so as to changethe surface state of the carbon fiber, so that when the carbon fiber and resin and other substrates are compounded to prepare the carbon fiber composite material, the anchoring points between the carbon fiber and the substrate can be increased, adhesion between the carbon fiber and the substrate is improved and the mechanical properties of the composite material are enhanced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

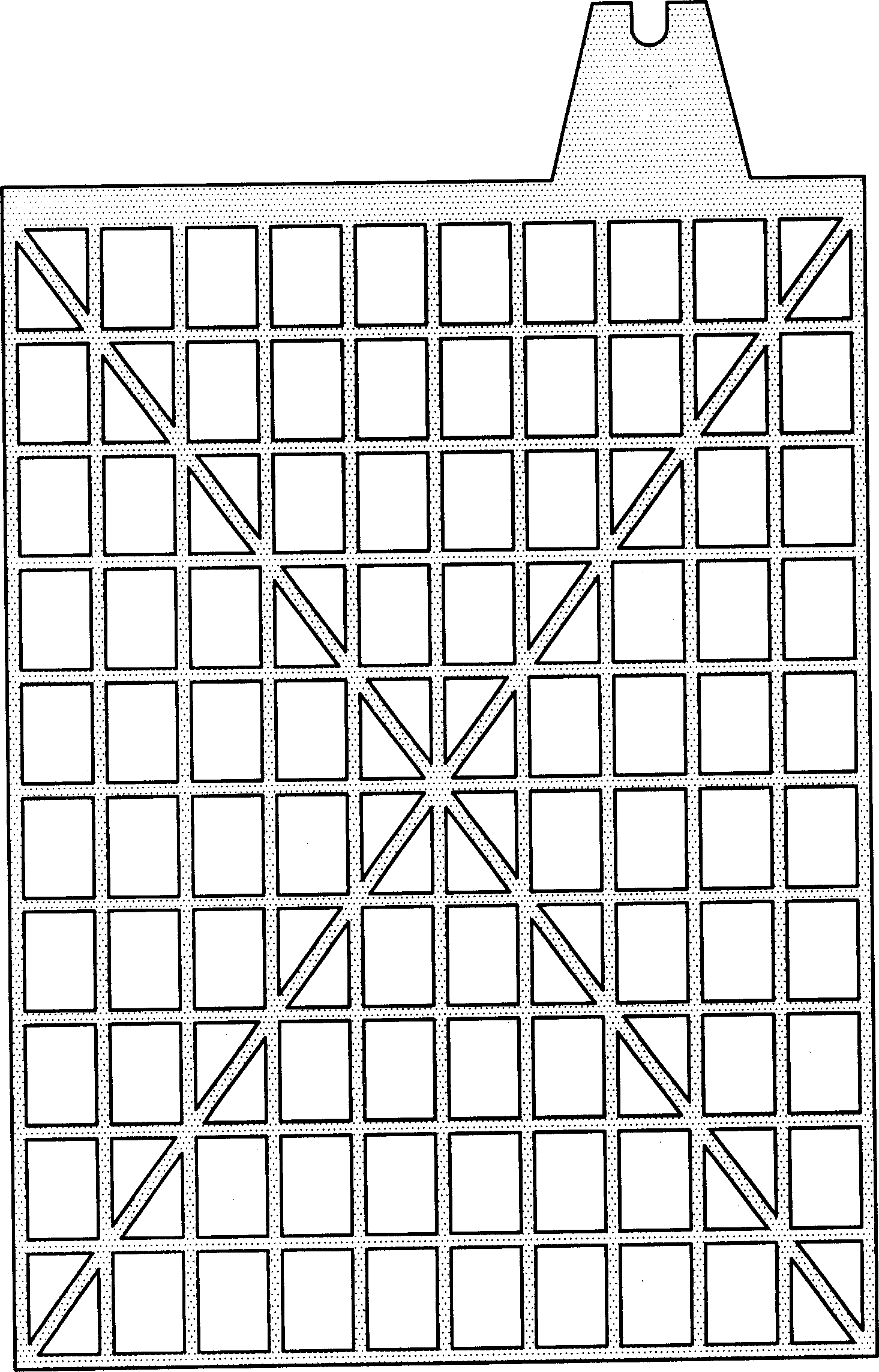

Nano carbon tube composite high-energy accumualtor-separator gate

The invention relates to the slab lattice of high-energy accumulator made of the composite nanometer carbon tube. The ingredient of the slab lattice includes nanometer carbon tube, carbon fiber and silicon nitride. With the said ingredient being mixed and with 107 floor glue being added and mixed evently, die stamping the said mixed material obtains the roughts. The agglutinated slab lattices areobtained by heat drying, agglutinating the roughs then cooling down the roughs slowly. Lead plaster in 3 days screen mesh is coated on the slab lattice. After 20-25 hours, the slab lattice can be used to assemble the accumulator.

Owner:乌日根

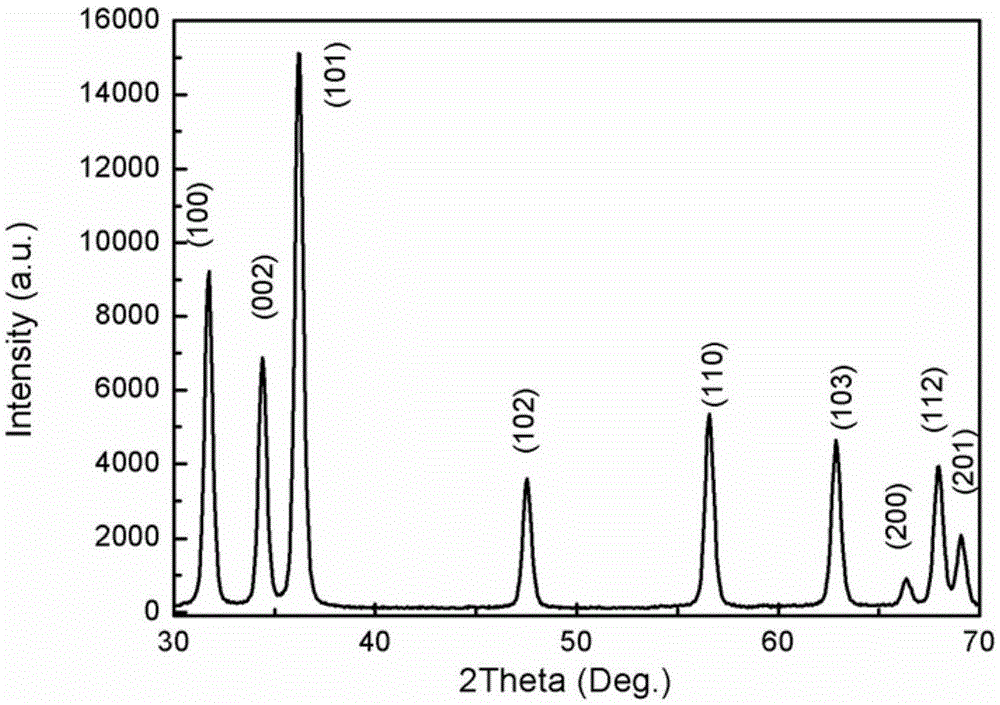

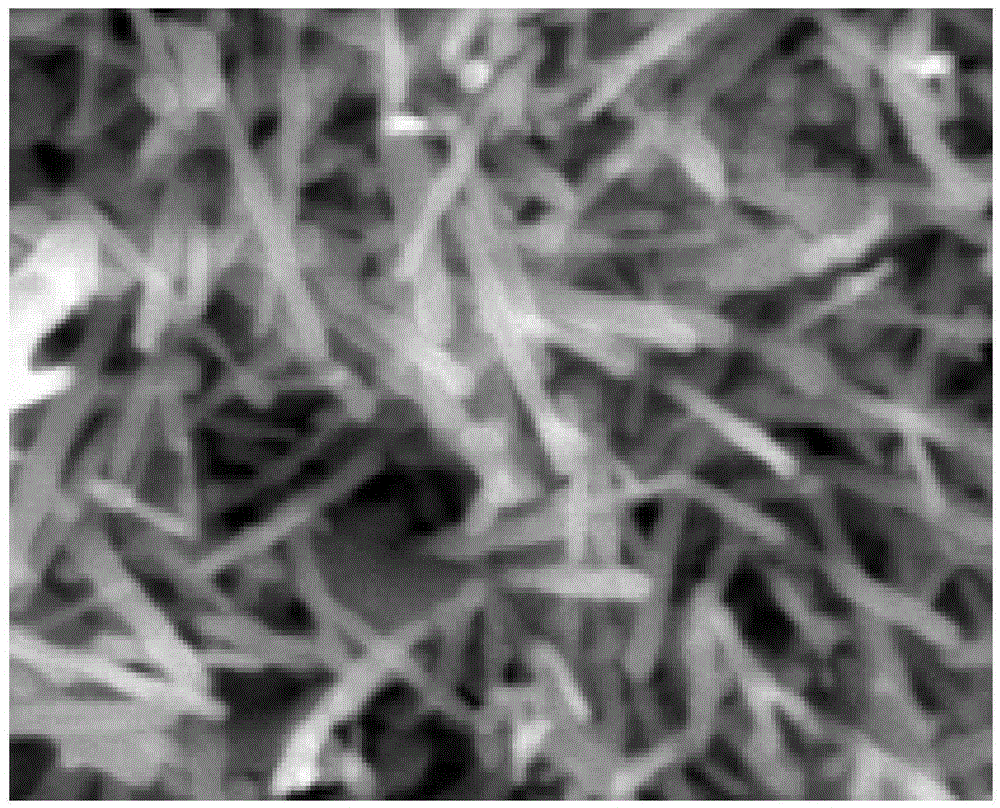

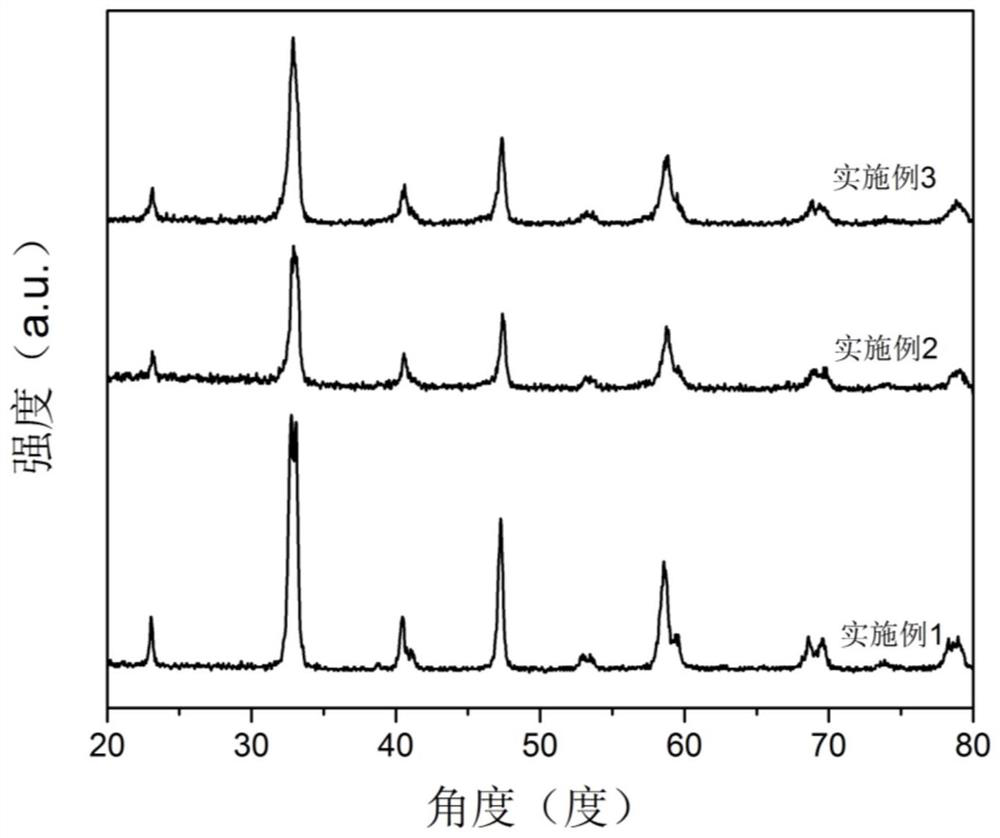

Method for preparing cobalt-doped zinc oxide nanorods through sol-gel

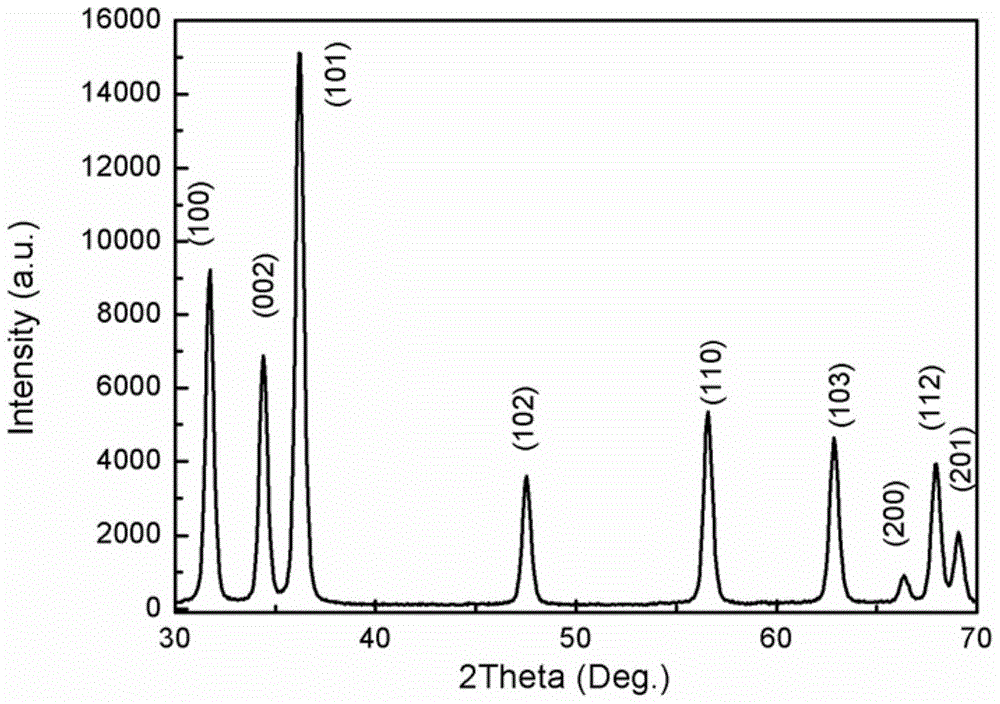

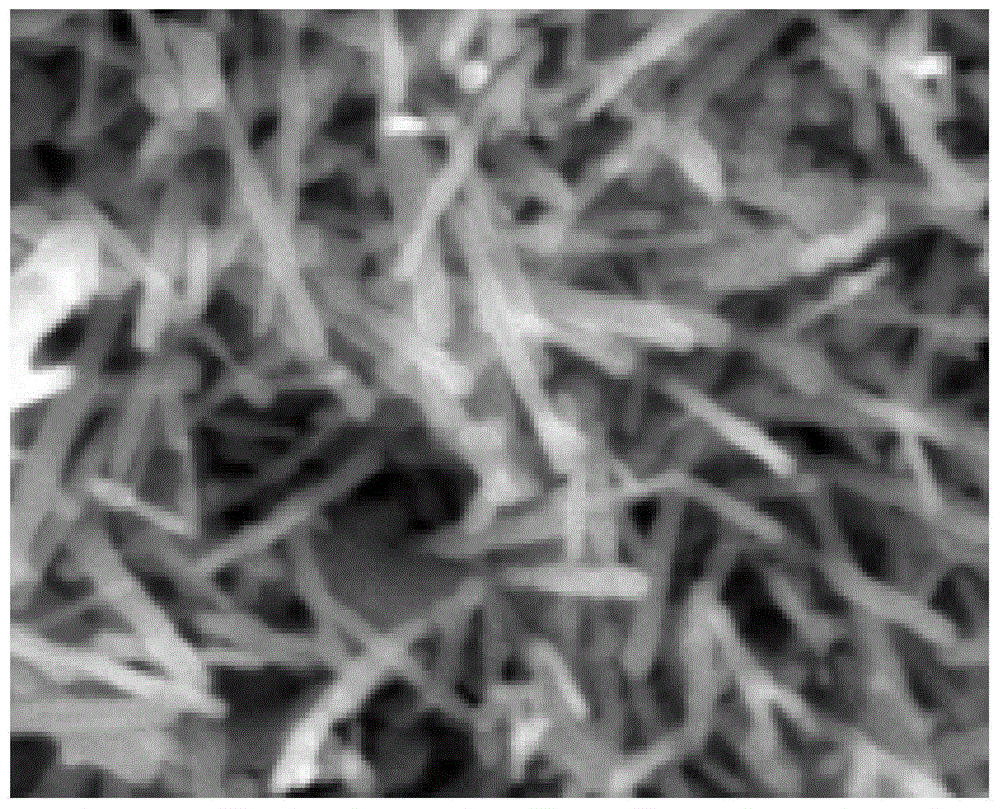

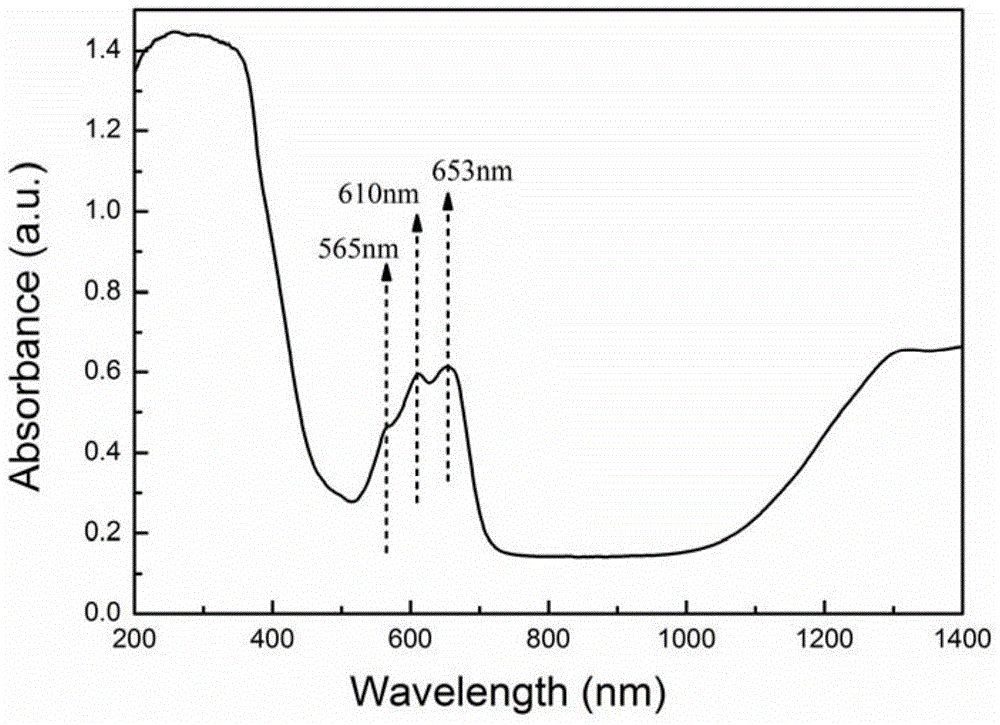

ActiveCN105314672ASimple processLow reaction temperatureMaterial nanotechnologyZinc oxides/hydroxidesAir atmosphereZinc Acetate Dihydrate

The invention discloses a method for preparing cobalt-doped zinc oxide nanorods through sol-gel. The method comprises the steps of dissolving dihydrate zinc acetate and tetrahydrate cobaltous acetate into ethylene glycol monomethyl ether according to the stoichiometric ratio of Zn<1-x>Co<x>O, stirring the mixture uniformly, and obtaining a mixed solution; dropwise adding ethanolamine to the mixed solution, conducting a reaction under the condition that the mixture is stirred at the temperature of 60-80 DEG C, cooling the mixture naturally to the room temperature after the reaction is ended, and obtaining clear cobalt-doped zinc oxide precursor sol; drying the clear cobalt-doped zinc oxide precursor sol, obtaining dried gel, then making the dried gel be subjected to a heat treatment process in the air atmosphere, and obtaining the clear cobalt-doped zinc oxide nanorods. According to the method, the cobalt-doped zinc oxide nanorods are prepared through a multicomponent uniform reaction sol-gel method, and the method has the advantages that the process is simple, the reaction temperature is low, the cost is low, the test process is easy to control, the product crystallinity degree is high, and the crystalline phase is pure, and the obtained clear cobalt-doped zinc oxide nanorods have ferromagnetism at the room temperature.

Owner:XIAN TECHNOLOGICAL UNIV

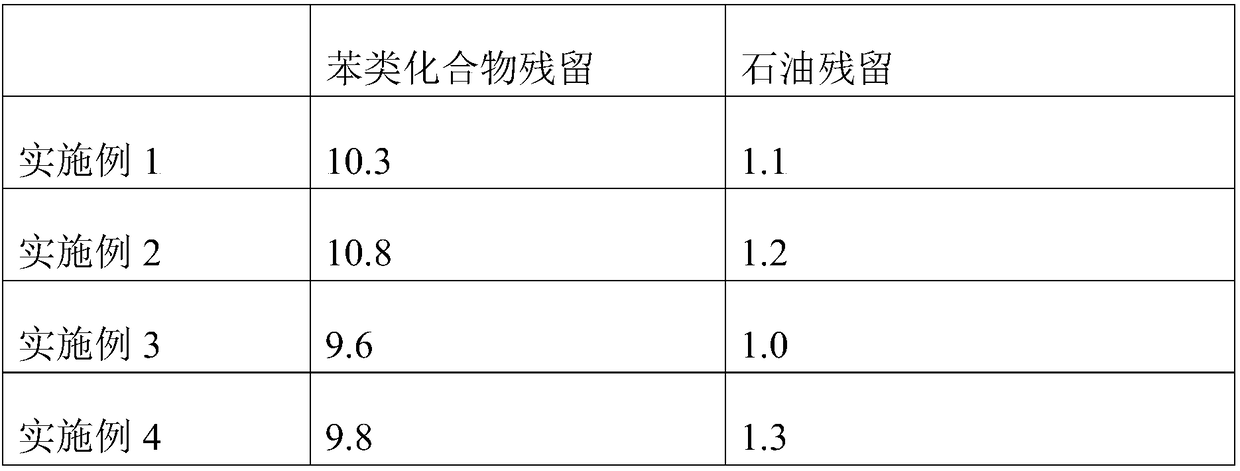

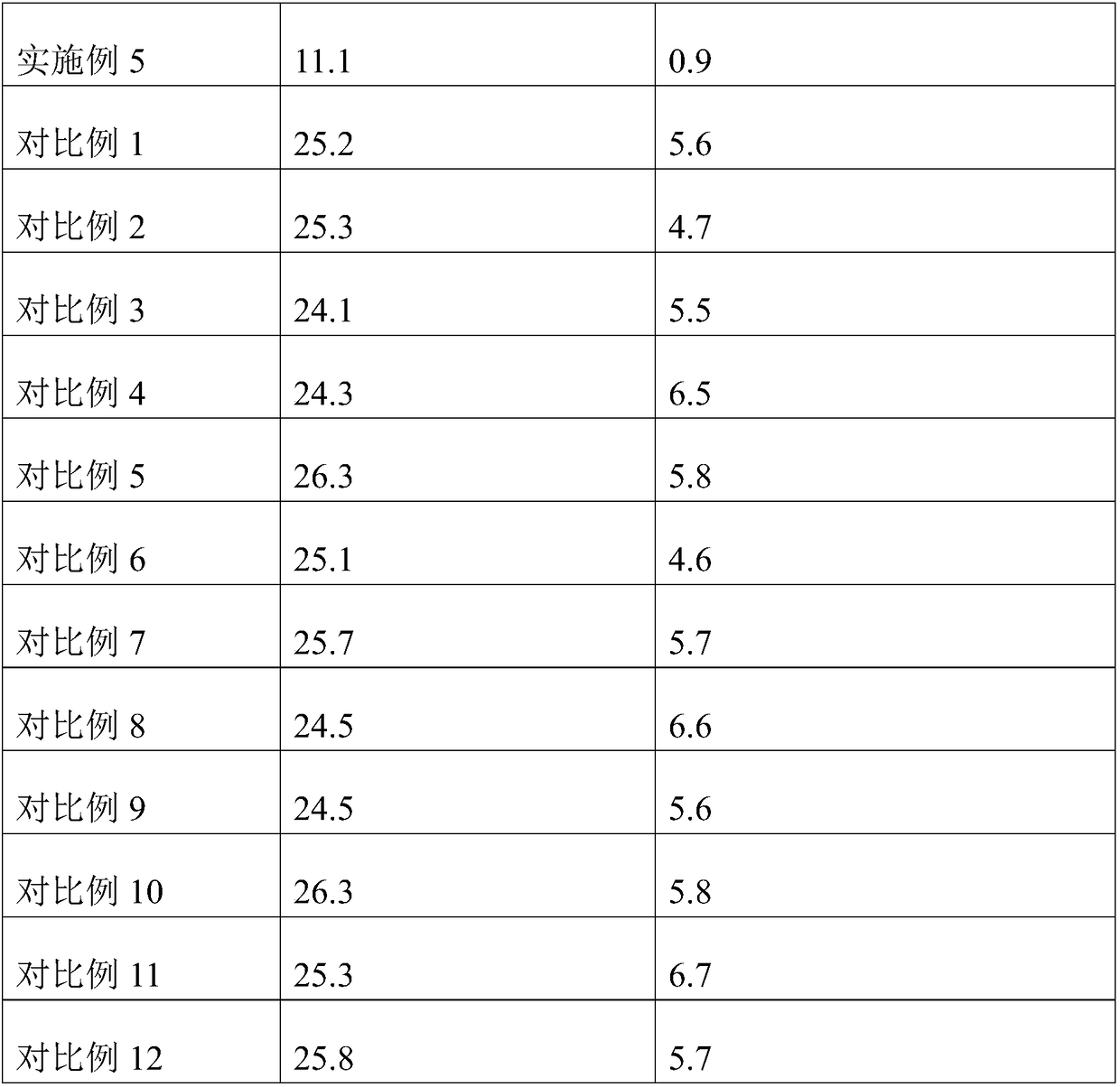

Compound coated slow-release fertilizer for garden planting and method for preparing compound coated slow-release fertilizer

InactiveCN106365795AExcellent fertilizer slow releaseImprove waterproof performanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSodium hydroxideHydrogen peroxide

The invention discloses a compound coated slow-release fertilizer for garden planting. The compound coated slow-release fertilizer comprises kernel fertilizers, inner-layer coating materials and outer-layer coating materials. The inner-layer coating materials wrap the surfaces of the kernel fertilizers, and the outer-layer coating materials wrap the surfaces of the inner-layer coating materials; urea, diammonium phosphate, potassium sulfate and grass carbon are mixed with one another to obtain the kernel fertilizers; a process for preparing the inner-layer coating materials include uniformly mixing corn starch and water with each other to obtain first mixtures, adding hydrogen peroxide and sodium hydroxide solution A into the first mixtures to obtain second mixtures, heating the second mixtures, then preserving heat of the second mixtures, adding sodium bisulfite solution into the second mixtures to obtain third mixtures, cooling the third mixtures, adding epichlorohydrin into the third mixtures to obtain fourth mixtures, dropwise adding sodium hydroxide solution B into the fourth mixtures to obtain fifth mixtures, carrying out constant-temperature reaction on the fifth mixtures and cooling reaction products until the temperatures of the reaction products reach the room temperature to obtain the inner-layer coating materials. The invention further discloses a method for preparing the compound coated slow-release fertilizer for garden planting. The compound coated slow-release fertilizer and the method have the advantages that the slow-release fertilizer prepared by the aid of the method is excellent in fertilizer efficiency slow-release and waterproof property, free of biological toxicity, good in film-forming ability and high in cohesiveness, and growth of garden crops can be promoted.

Owner:天长市天兴园林绿化工程有限公司

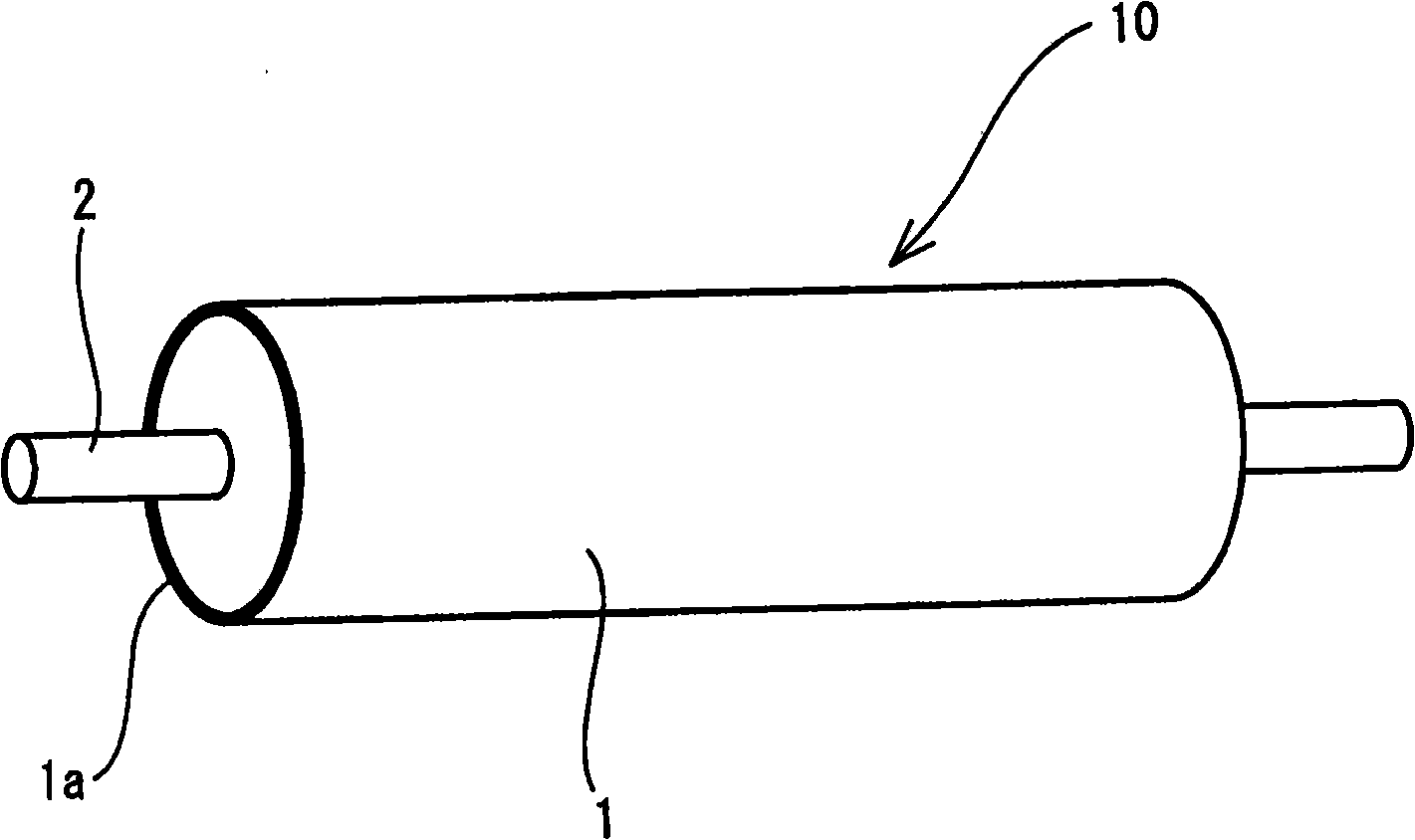

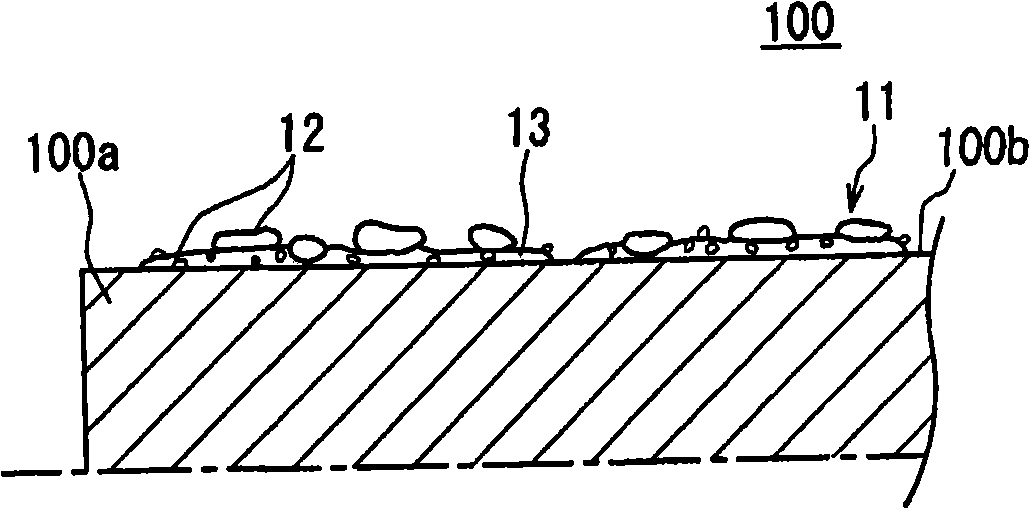

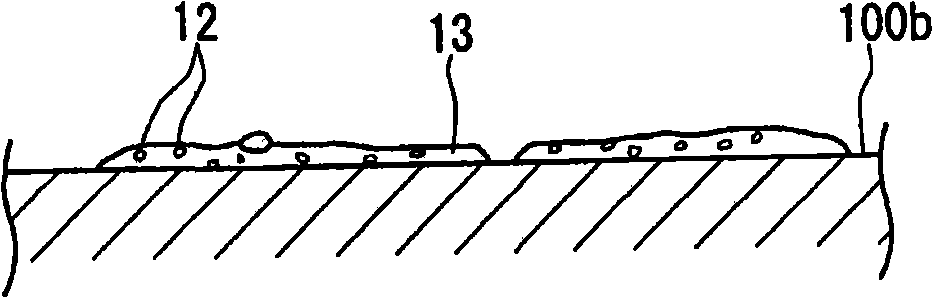

Method for recycling an image-forming member

InactiveCN101315535ANo change in dimensional accuracyDoes not change contact stateElectrographic process apparatusElastomerUltraviolet

The present invention provides a method for recycling a spent image-forming member mounted inside an image-forming apparatus to reuse the image-forming member. In the method, the image-forming member is made of an elastomer before the image-forming member is recycled; and when a recycling work is performed, a surface of the image-forming member is not abraded, but irradiated with ultraviolet rays or ozone at least once to decompose or / and deteriorate a deposit which has attached to the surface thereof in a use thereof so that the deposit is removed from the surface thereof.

Owner:SUMITOMO RUBBER IND LTD

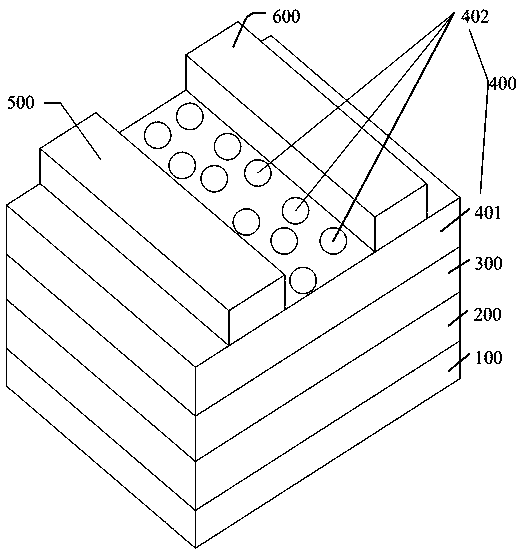

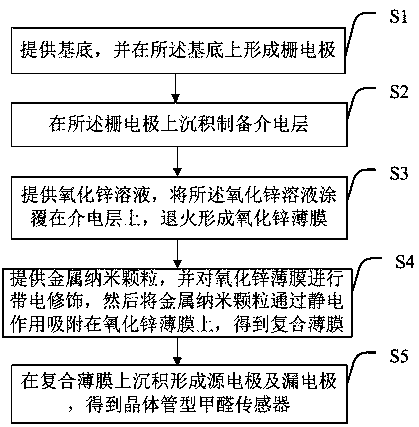

Transistor type formaldehyde sensor and manufacturing method thereof

ActiveCN109030564AChanging the carrier concentrationFix stability issuesMaterial analysis by electric/magnetic meansComposite filmOptoelectronics

The invention discloses a transistor type formaldehyde sensor and a manufacturing method thereof. The transistor type formaldehyde sensor comprises a substrate, a gate electrode arranged on the substrate, a dielectric layer arranged on the gate electrode, a composite film arranged on the dielectric layer, a source electrode and a drain electrode arranged on the composite film, wherein the composite film is a zinc oxide film onto which the metal nanoparticles are adsorbed. The transistor type formaldehyde sensor provided by the invention has specific selectivity for formaldehyde and strong anti-interference performance, and solves the problem that the stability and selectivity of the formaldehyde sensor are poor in the prior art.

Owner:SHENZHEN UNIV

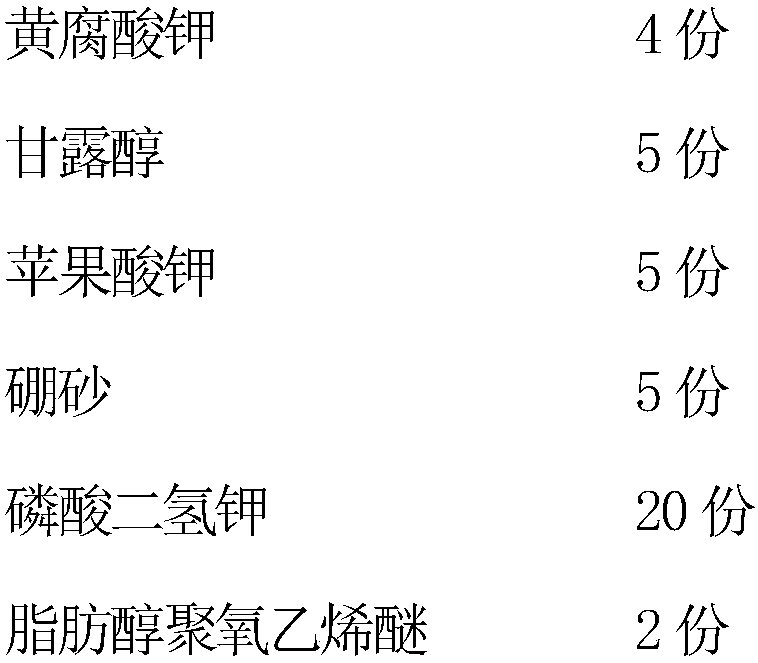

Humic acid fertilizer composition and application thereof, and humic acid soluble fertilizer and application thereof

InactiveCN109574767AImprove anti-flocculation abilityIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPlant rootsVitamin C

The invention discloses a humic acid fertilizer composition and application thereof, and a humic acid soluble fertilizer and application thereof. The humic acid fertilizer composition comprises, by weight, 4-10 parts of potassium fulvic acid, 0.4-20 parts of sugar alcohol and 4-12 parts of organic potassium acid. The technical threshold of application of the humic acid fertilizer is reduced, fertilization mode is simplified, and safety and convenience in agricultural production are both guaranteed. With synergistic effect of the humic acid fertilizer composition, growth of plant roots is improved, content of vitamin C and soluble sugar is increased, yield and quality of plants are both increased, and yield increasing effect keeps stable.

Owner:SICHUAN GUOGUANG AGROCHEM

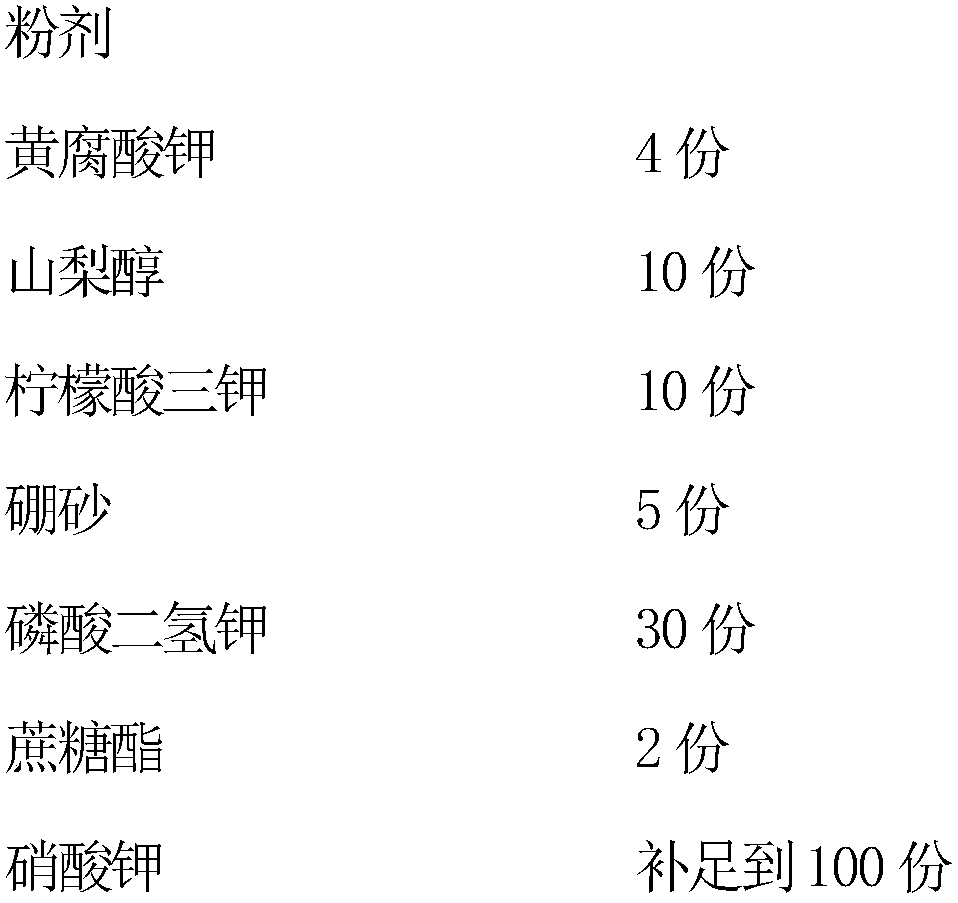

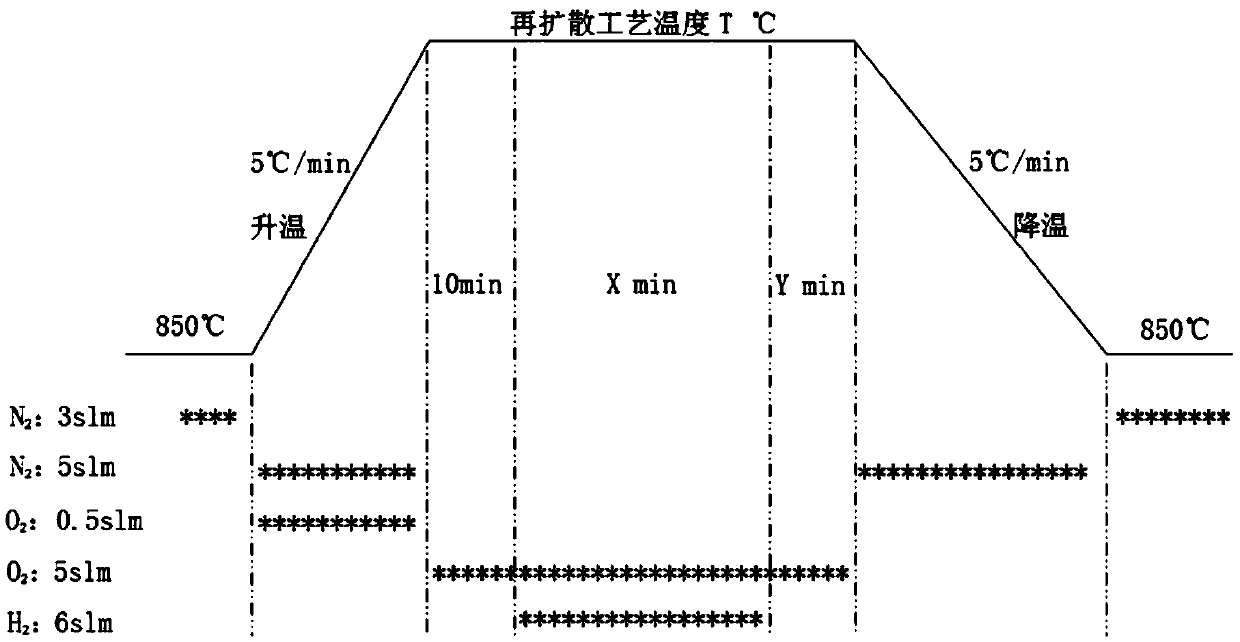

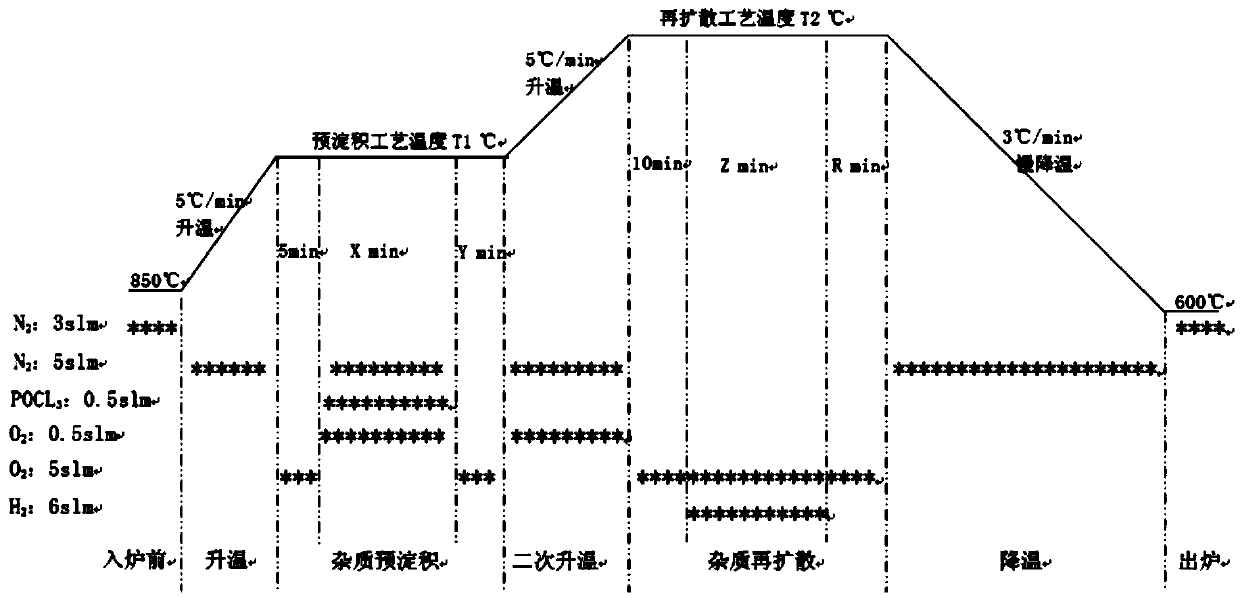

Impurity diffusion process in semiconductor device preparation process

ActiveCN109671620AImprove the contamination problemPlay an annealing effectFinal product manufactureSemiconductor/solid-state device manufacturingImpurity diffusionDevice material

The invention discloses an impurity diffusion process in a semiconductor device preparation process, and belongs to the technical field of semiconductor device manufacturing. The process first performs an impurity pre-deposition process, and then a diffusion furnace is heated to a re-diffusion temperature T2 at a rate of 5 DEG C / min under a mixed atmosphere of nitrogen and oxygen; the impurities are re-diffused, and finally the diffusion furnace is placed under a nitrogen atmosphere of 5 slm to be cooled to below 600 DEG C at a rate of 3 DEG C / min, and a silicon wafer is taken put and then naturally cooled. The impurity pre-deposition and diffusion process in the furnace are completed at one time to avoid the influence of repeated lifting and lowering temperature on product parameters andperformance and shorten a large amount of process time.

Owner:NO 47 INST OF CHINA ELECTRONICS TECH GRP

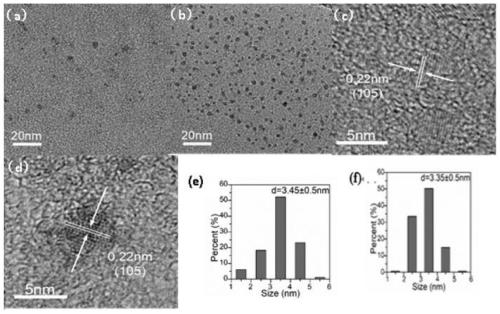

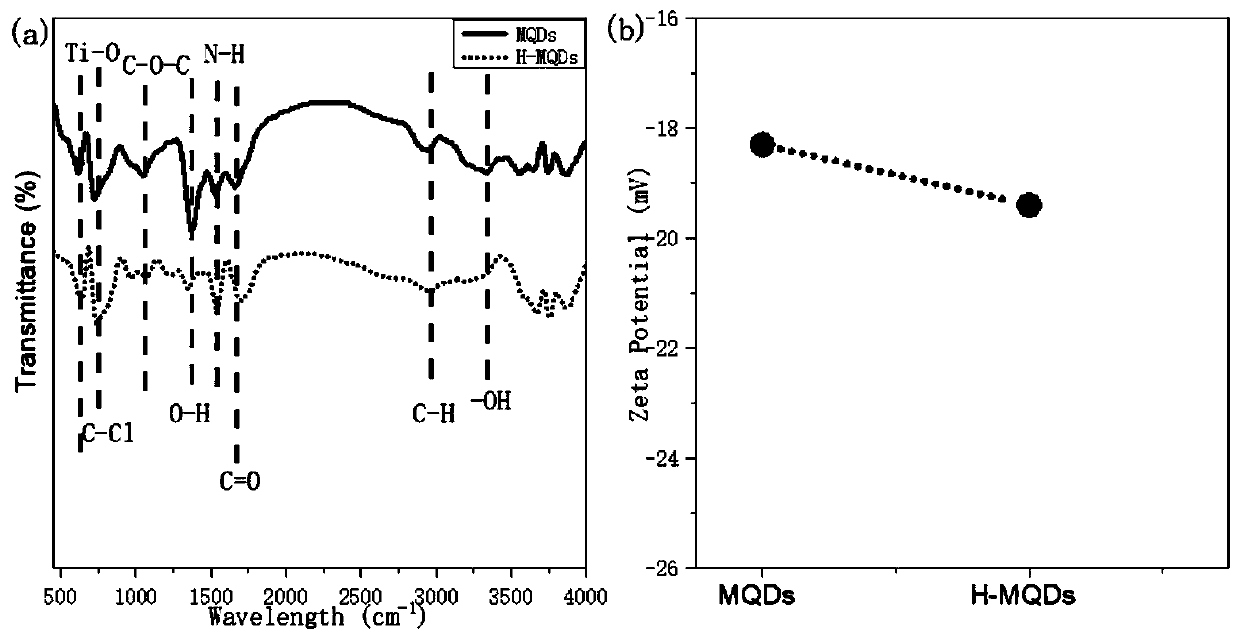

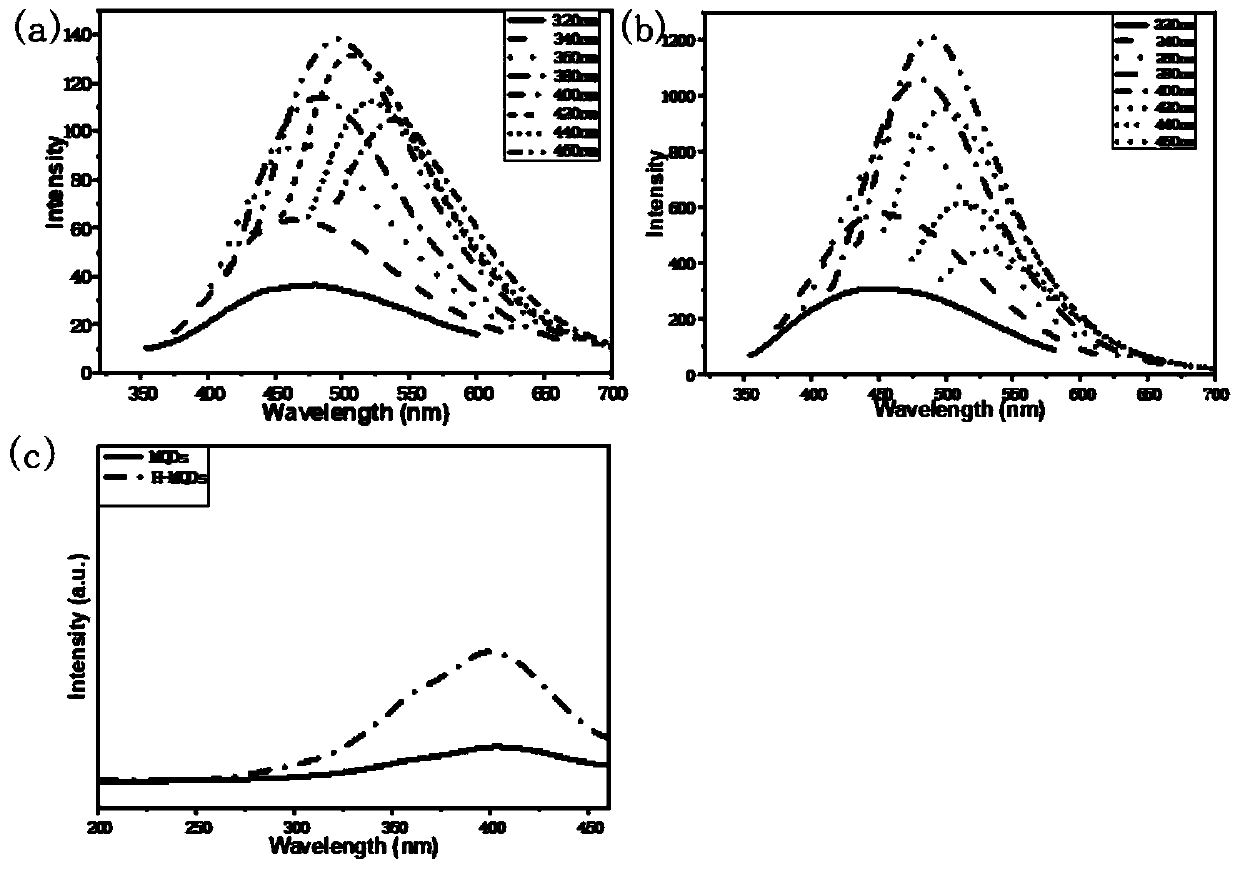

Method for enhancing fluorescence of MXene quantum dots

ActiveCN111187619AThe enhancement method is simpleGood effectNanoopticsLuminescent compositionsChemical physicsPhotoluminescence

The invention relates to the field of fluorescence enhancement application, in particular to a method for enhancing fluorescence of MXene quantum dots. The method comprises the following specific steps: firstly, adding H2O2 with the volume fraction of 30% into an MQDs solution with the concentration of 0.1 mg / mL; carrying out ultrasonic treatment on the MQDs solution for 4-6 minutes to uniformly mix the MQDs solution, and naming the mixed solution as H-MQDs. Quantum dots (MQDs) derived from a two-dimensional MXene material not only reserve excellent conductivity, temperature and chemical stability of an original MXene layered material, but also show good water solubility and photoluminescence performance, so that the MQDs have great application potential in the fields of biological imagingand the like. The MQDs can be prepared by hydrothermal and alkali reflux methods, and no matter which method is used for preparing the MQDs, hydrogen peroxide (H2O2) treatment can be used for changing the surface state of the MQDs, so that the fluorescence emission capacity of the MQDs is improved.

Owner:UNIV OF SCI & TECH BEIJING

Antistatic plastic composite material for electric power fitting and preparation method of antistatic plastic composite material

The invention discloses an antistatic plastic composite material for an electric power fitting. The antistatic plastic composite material is prepared from the following raw materials in parts by weight: 100 parts of junked and abandoned nylon 66 plastic, 2.5 to 2.8 parts of polybutadiene epoxy resin, 23 to 27 parts of glass fiber, 9 to 10 parts of aluminum nitride, 1.7 to 1.9 parts of nano calcium carbonate, 6 to 8 parts of dimethyl formamide, 2.6 to 2.9 parts of triethylene glycol diisooctoate, 7 to 9 parts of silane coupling agent KH560, 11 to 13 parts of sericite powder, 1.4 to 1.7 parts of secondary-alkyl sulfonate and 4 to 6 parts of polyethylene wax. Nylon is modified into a matrix through the epoxy resin; the modified glass fiber is used as a reinforcing material; the nano calcium carbonate is added into the material after being subjected to graft modification treatment through the dimethyl formamide; afterwards, the composite material prepared by matching with other effective components is used for better solving the problems of magnetic hysteresis loss and eddy current loss, avoids electric energy loss, and has the advantages of being antistatic, resistant to wear and high in mechanical strength, and the like.

Owner:马鞍山市华能电力线路器材有限责任公司

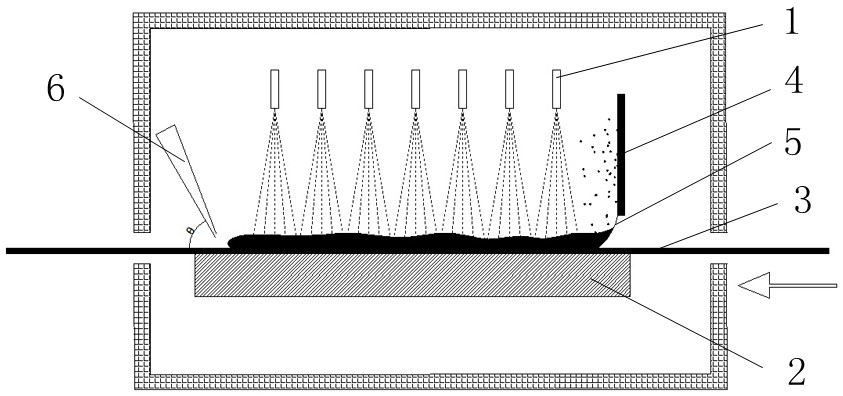

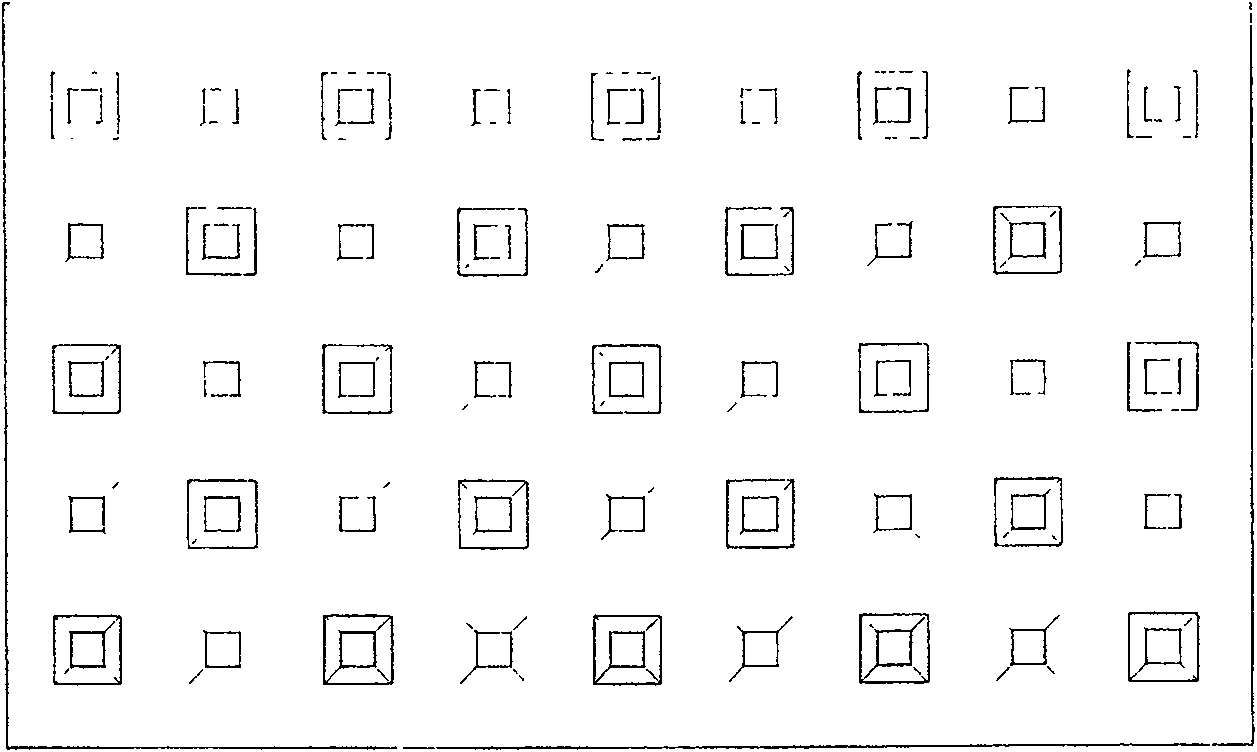

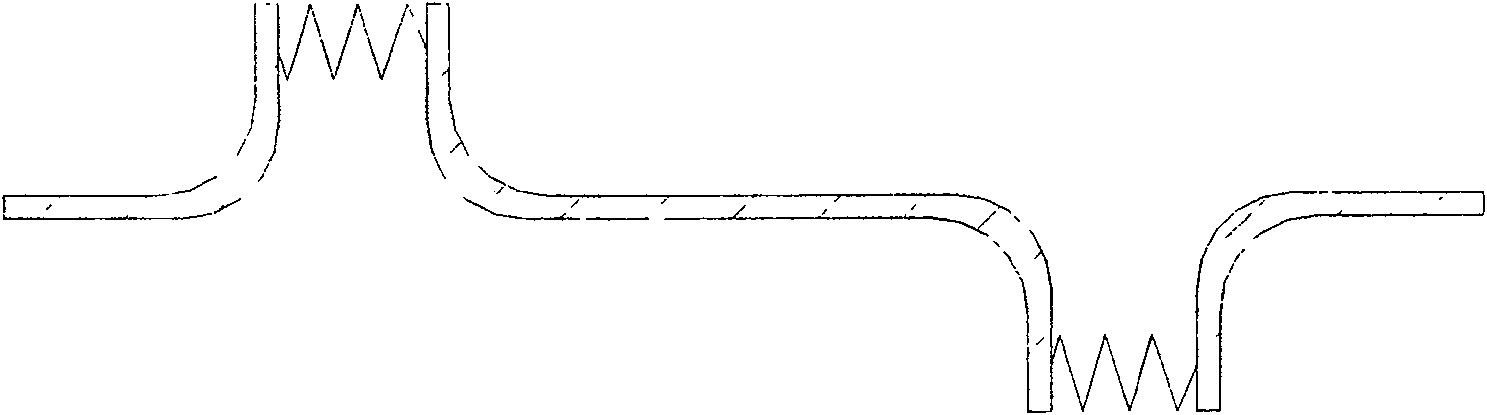

Etching device for fine circuit

PendingCN112530841APrevent take outAvoid wastingSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention relates to an etching device for a fine circuit and belongs to the technical field of circuit board manufacturing. The etching device comprises an etching spraying disc and a bearing plate, wherein the bearing plate bears a product below the product, the etching spraying disc is arranged above the product, the etching spraying disc is composed of multiple rows of etching nozzles, thenozzles of the etching spraying disc continuously spray etching liquid to the product below at a certain pressure for etching, and a baffle is arranged above the front end of the product in the advancing direction; the baffle plate is arranged at the front end of the etching spray disc, the bottom of the baffle plate is provided with a spoiler, the baffle plate prevents spray liquid medicine fromsplashing to a pretreatment surface of a product, and the spoiler prevents the liquid medicine from flowing back to the pretreatment surface of the product. The etching device is advantaged in that the etching liquid can be effectively prevented from being contacted with the pretreatment surface of the product too early due to sputtering and backflow, and a surface state of the product is changed, so etching precision of a circuit is ensured; the influence of the pool effect on the line precision can be effectively reduced or reduced, and the waste of the etching liquid and the pollution to the liquid medicine of the next treatment tank are avoided.

Owner:LEADER TECH ELECTRONICS SHENZHEN INC

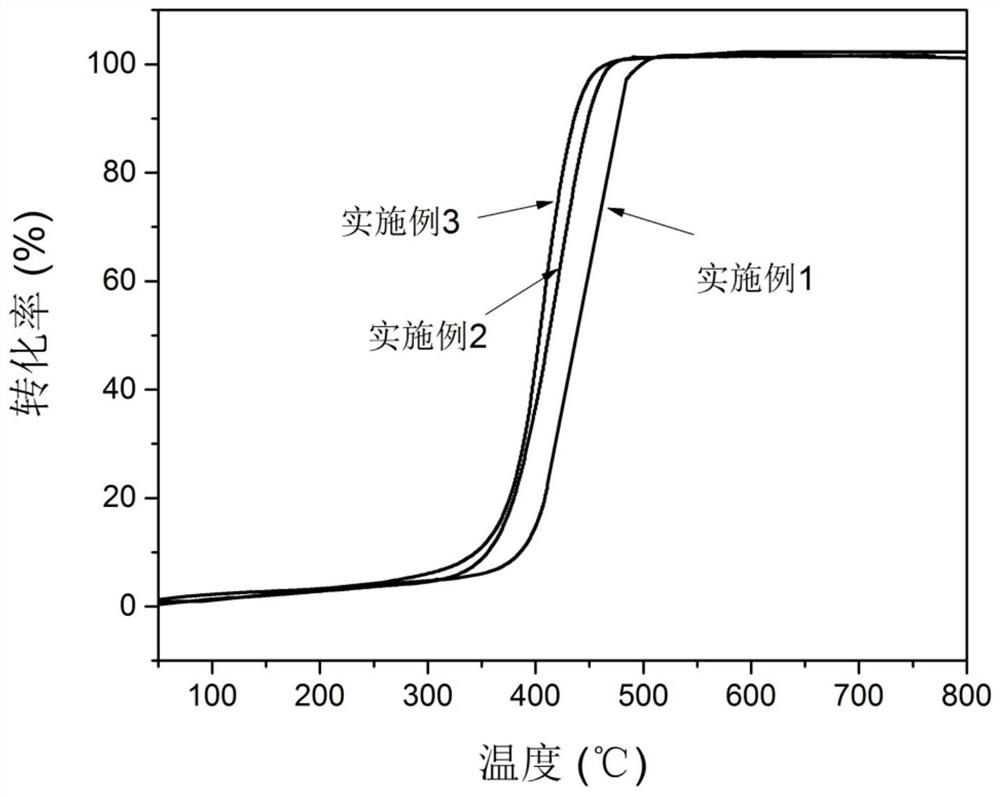

Surface-modified perovskite catalyst as well as preparation method and application thereof

PendingCN111686755AChange surface stateGuaranteed supplyHuman health protectionExhaust apparatusPtru catalystPhysical chemistry

The invention discloses a surface modified perovskite catalyst as well as a preparation method and application thereof, wherein hydrogen peroxide is used for treating the prepared perovskite catalyst,so that the surface modified perovskite catalyst is obtained. The initial perovskite catalyst is prepared through a sol-gel process, wherein the preparation method has the advantages that the operation is simple and convenient and is short in time, and then hydrogen peroxide is directly used for carrying out surface oxidation modification on the initial perovskite catalyst, so that the surface state of the perovskite catalyst is changed, and the surface area and the stability are improved. The catalyst is applied to the field of diesel engine tail gas purification treatment, emission of sootparticles can be effectively reduced, and therefore the purpose of reducing the air pollution degree is achieved.

Owner:TIANJIN UNIV

Thin film for solar cell backplane and preparation method of thin film

InactiveCN107383798AImprove stabilityImprove adhesionPhotovoltaic energy generationSemiconductor devicesPolytetramethylene terephthalateSolar cell

The invention discloses a thin film for a solar cell backplane, and belongs to the technical field of solar cell backplanes. The thin film comprises the following raw materials in parts by weight: 11-13 parts of polyethylene-1,4-buthylene adipate glycol, 18-22 parts of fluorine-containing resin, 8-10 parts of polybutylene terephthalate resin, 4-6 parts of polyetheretherketone, 4-6 parts of silicon dioxide, 3-5 parts of titanium dioxide, 3-5 parts of decabromodiphenyl ethane, 7-9 parts of acetyl tributyl citrate, 0.1-0.3 part of a UV absorbent, 0.5-1.5 parts of a coupling agent and 1-3 parts of a surfactant. The invention also discloses a preparation method of the thin film for the solar cell backplane. The thin film provided by the invention has advantages of simple preparation, good adhesion ability, relatively excellent high-temperature resistance and long service life.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

Impact-resistant plastic electric power fitting composite material and making method thereof

The invention discloses an impact-resistant plastic electric power fitting composite material. The composite material is made from, by weight, 100 parts of waste nylon 66 plastic, 2.1-2.4 parts of o-cresol formaldehyde epoxy resin, 20-21 parts of glass fibers, 1.1-1.4 parts of nanometer magnesium oxide, 18-20 parts of carbon black, 6-8 parts of a silane coupling agent KH550, 3-5 parts of chlorinated paraffin, 6-8 parts of a polyurethane emulsion and 4-6 parts of wheat straw fiber micro-powder. Nylon is modified with the epoxy resin to form a matrix, modified glass fibers are adopted as a reinforcement material, the nanometer magnesium oxide grafted and modified with the polyurethane emulsion is added to a material, and other effective components are adopted to prepare the composite material, so the composite material has the advantages of solving of hysteresis loss and eddy current loss, no electric energy loss, high impact resistance, high mechanical strength and long ageing resistance.

Owner:马鞍山市华能电力线路器材有限责任公司

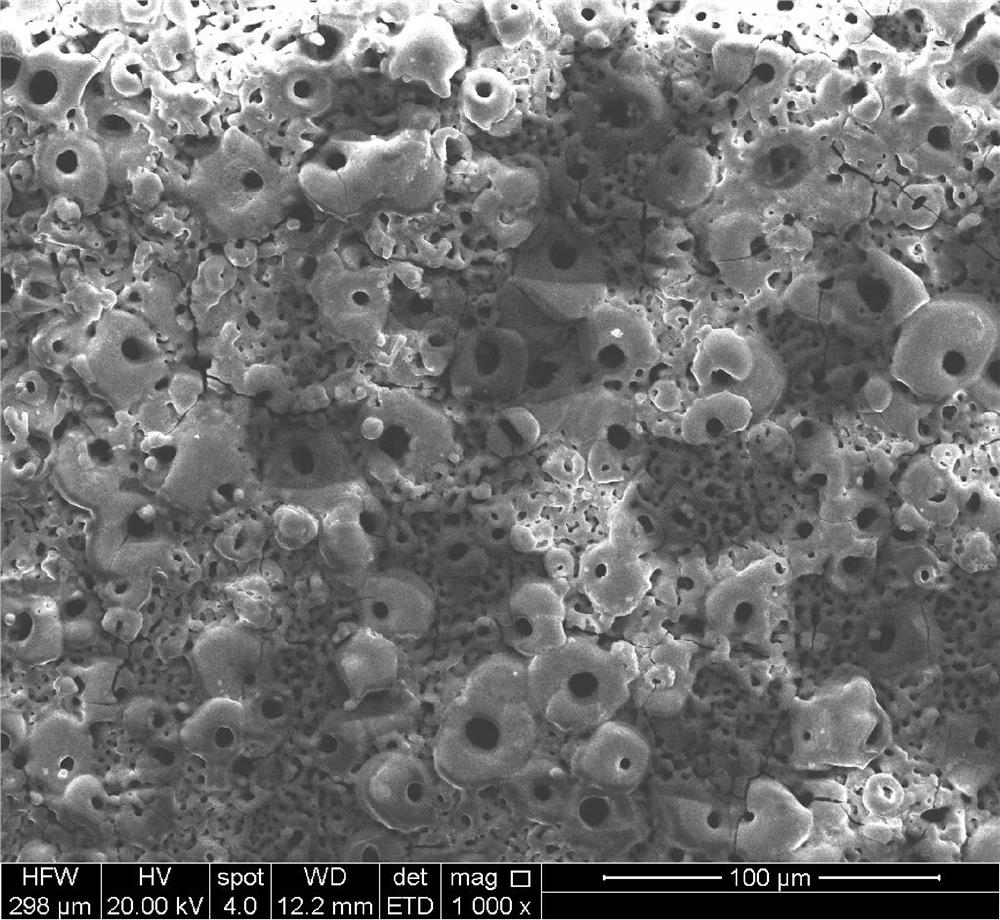

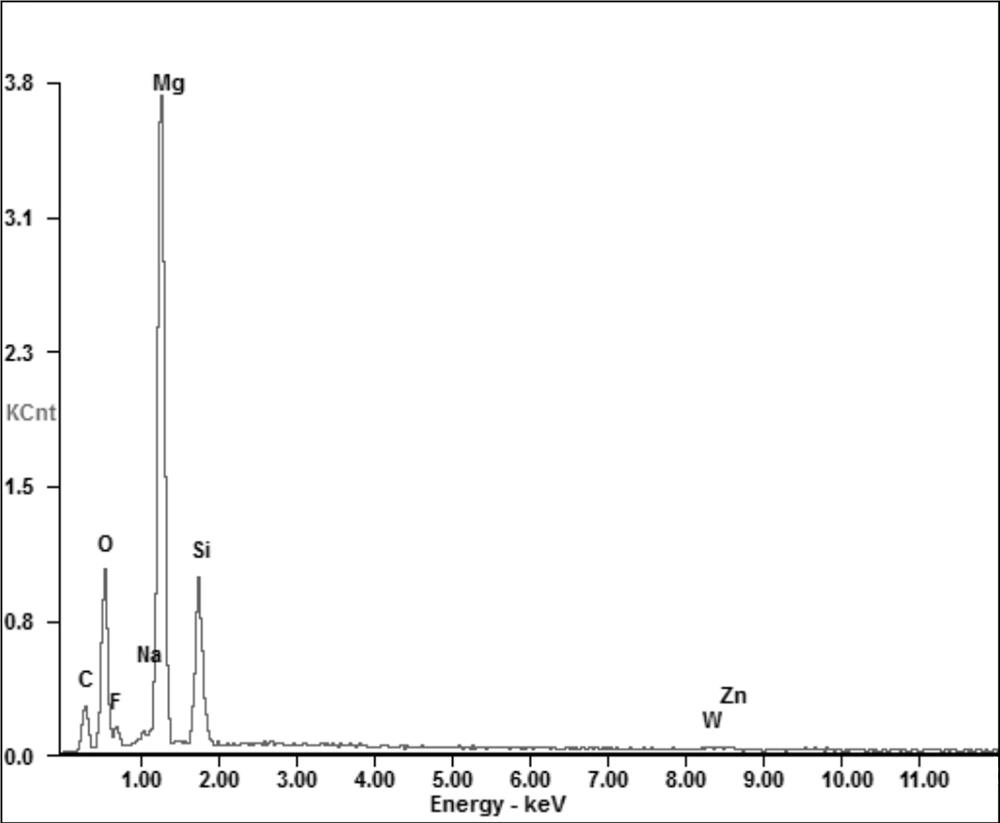

Preparation method of electrolytic solution and black coating for micro-arc oxidation of magnesium alloy surface

ActiveCN112342591BImprove adsorption capacityFacilitated DiffusionAnodisationMicro arc oxidationMg alloys

The invention discloses a preparation method of an electrolytic solution for micro-arc oxidation on the surface of a magnesium alloy and a black coating. The electrolytic solution includes a main film-forming agent, an auxiliary film-forming agent, a main coloring salt, a complexing agent and deionized water; the main coloring salt is metal copper salt; the complexing agent is composed of polycondensed phosphate, organic phosphonate and tartrate; and in the electrolyte solution, the content of the main film-forming agent is 5~50 g / L; the content of the auxiliary film-forming agent is 1~ 30 g / L; the content of the main coloring salt is 1~20 g / L; the content of various complexing agents can be compounded at 1~20 g / L. The electrolyte solution is not easy to produce precipitation in the micro-arc oxidation process, has high stability, and has a long service life; the electrical parameters can also be adjusted in a wide range, and extreme discharge is not easy to occur, and the film forming efficiency is high; and the electrolyte solution is used The prepared black coating has high blackness, slight color difference, low surface roughness, high hardness, good corrosion resistance, strong adhesion, is not easy to decolorize, and has excellent thermal control performance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Production method of multilayer printed circuit board

InactiveCN111263536AIncrease productivityStrong and goodInsulating layers/substrates workingConductive material chemical/electrolytical removalMechanical engineeringPrinted circuit board

The invention discloses a production method of a multilayer printed circuit board. The method specifically comprises the steps of S1, preparing an inner-layer board; S2, carrying out surface treatmenton the inner-layer board; S3, preparing a prepreg; S4, superposing the inner-layer board and the prepreg through a laminating machine, and then laminating the inner-layer board and the prepreg; S5, conducting drilling and copper deposition, enabling the laminated circuit board to be sequentially subjected to the procedures of drilling, deburring, photoresist residue removal, chemical copper deposition and electroplating, and communicating the upper inner-layer board and the lower inner-layer board; S6, preparing an outer-layer board; S7, carrying out wet ink character printing by adopting full-automatic equipment; and S8, carrying out size, surface defect and electrical property detection on the printed circuit board product, and packaging the qualified product. According to the invention, the inner-layer board is produced by a subtracting method, the outer-layer board is produced by an addition method, the two methods are combined, the production efficiency can be greatly improved, and by improving and optimizing the reagent formula of the prepreg and the surface structure of the inner-layer board, the physical performance of the prepreg is improved, the strength of the multilayer circuit board is improved, and looseness is avoided.

Owner:SHENZHEN TONGCHUANGXIN ELECTRONICS

Preparation method of etched anodic oxidation aluminum plate

The invention discloses a preparation method of an etched anodic oxidation aluminum plate. The preparation method comprises the steps of acid etching polishing treatment or alkali etching matte treatment, anodic oxidation, cleaning, coloring, water washing, hole sealing and the like. According to the preparation method, anodic oxidation treatment is carried out on an aluminum sheet material whichis already subjected to matte or polishing treatment to obtain a bright, clean and highly transparent oxide film layer. By means of the oxide film layer, the surface state and performance of the aluminum plate material are changed, the corrosion resistance, the film bonding capacity and the hardness of the aluminum plate material are improved, and the surface of the aluminum plate material is protected. Moreover, the transparency of the oxide film layer is high, so that etching lines of the etched aluminum plate are clear, and then eye-catching surfaces with a plurality of colors can be obtained by means of coloring, and a better decoration effect is realized. The aluminum plate treated by the surface treatment process is immune from discoloration, fading, corrosion and film layer fallingafter being used for 1-2 years, thereby being long in service life, safe and environmentally friendly.

Owner:吴金发

Pollution repairing method for water polluted by organic matters

ActiveCN108947089ANo secondary pollutionChange surface stateWater contaminantsMultistage water/sewage treatmentAluminum silicateBall mill

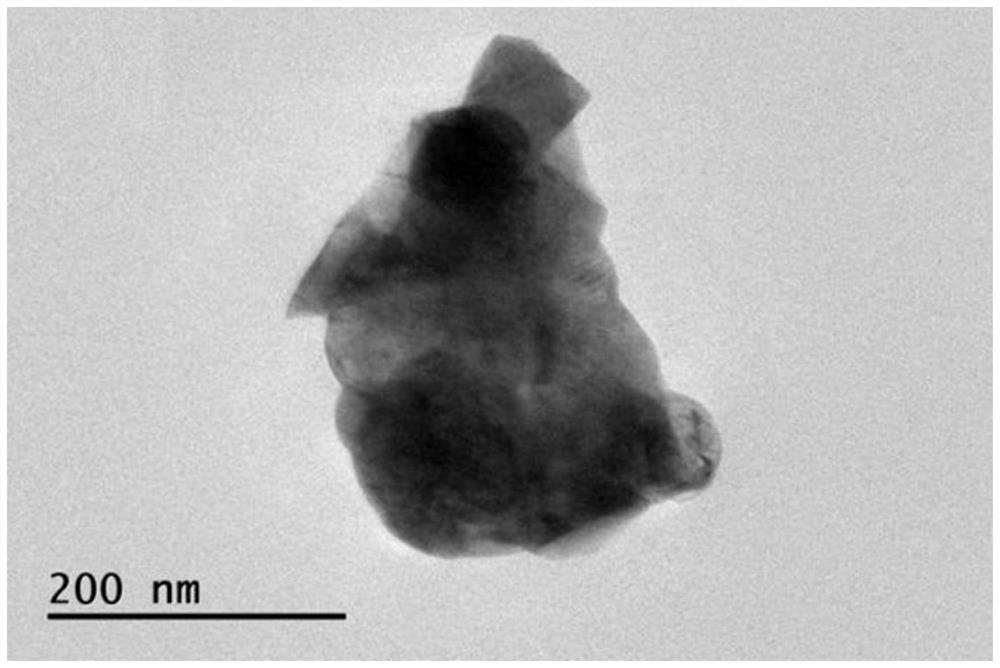

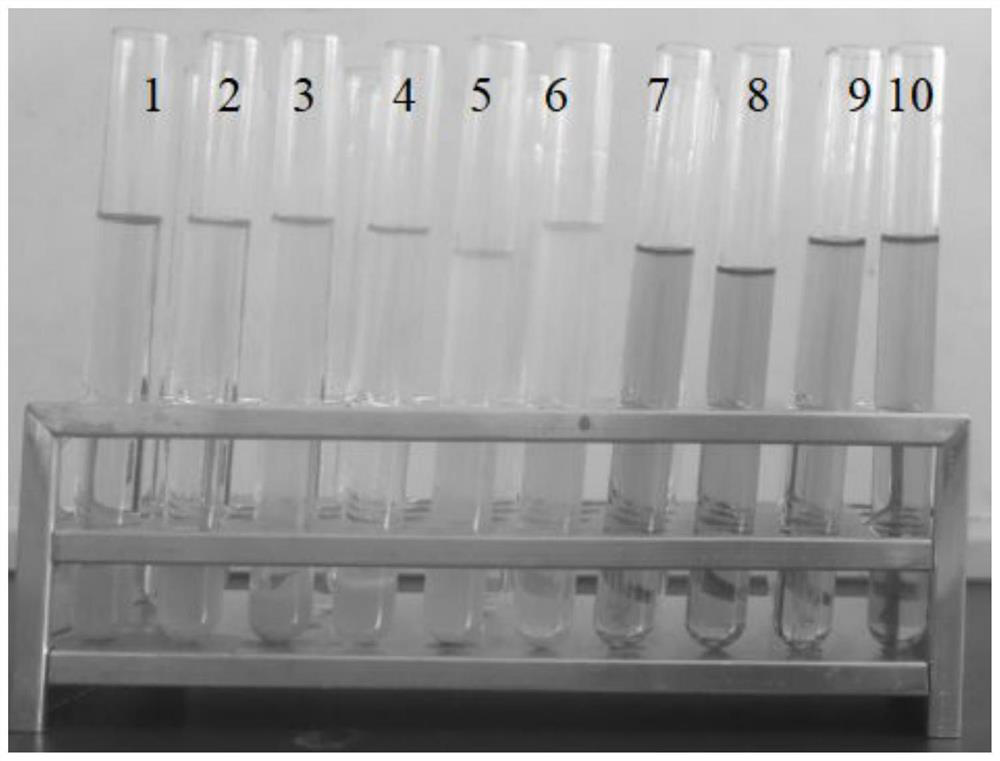

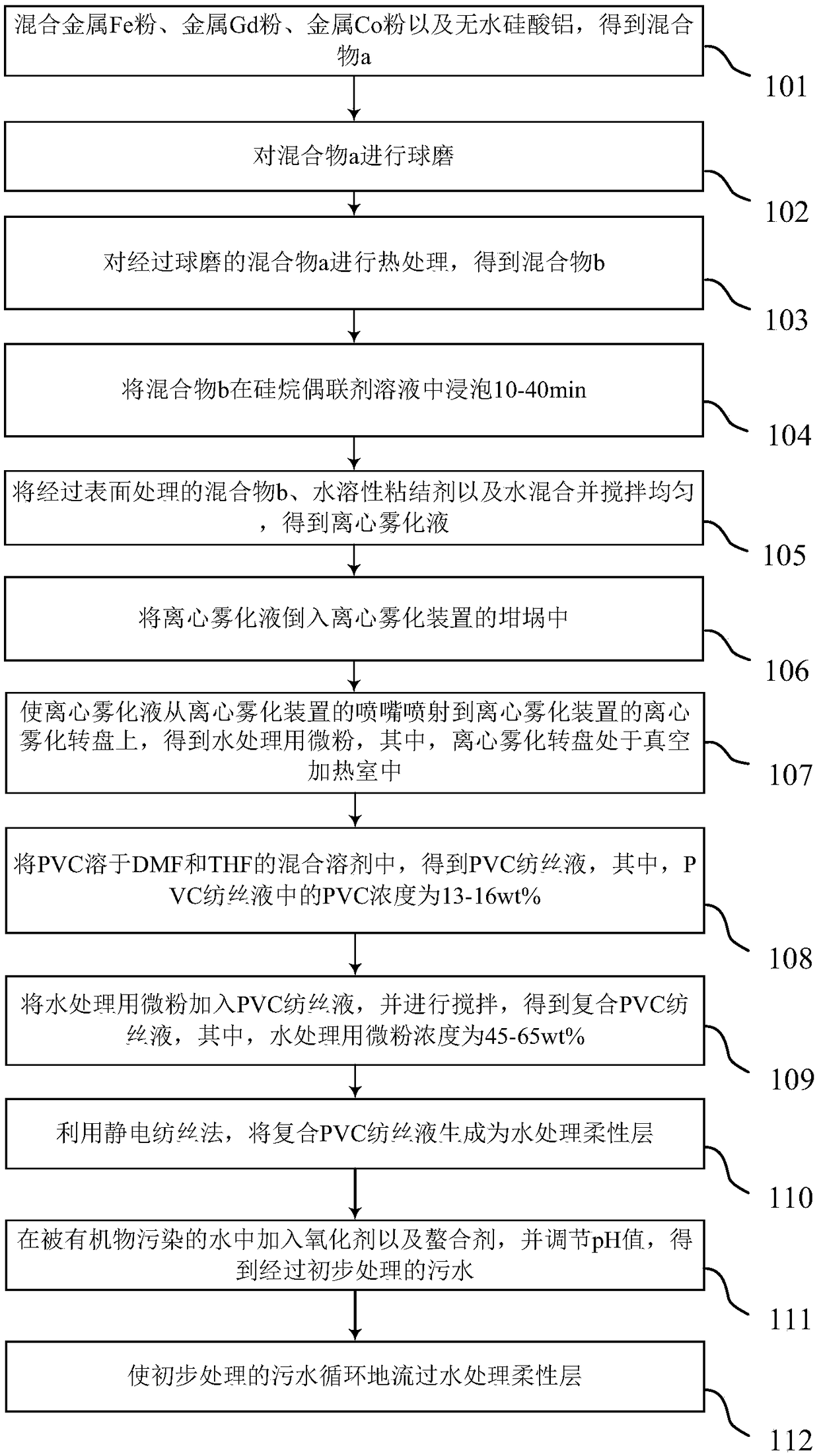

The invention provides a pollution repairing method for water polluted by organic matters. The method comprises the following steps: mixing metal Fe powder, metal Gd powder, metal Co powder and anhydrous aluminum silicate to obtain a mixture a; ball-milling the mixture a; thermally treating the ball-milled mixture a and carrying out surface treatment and centrifugal atomization to obtain micro powder for water treatment, adding the micro powder for water treatment to a PVC (Poly Vinyl Chloride) spinning solution and stirring to obtain a composite PVC spinning solution; forming the composite PVC spinning solution into a water treatment flexible layer by utilizing an electrospinning method; adding an oxidizing agent and a chelating agent to the water polluted by the organic matters and adjusting the pH (Potential of Hydrogen) value to obtain initially-treated sewage; and enabling the initially-treated sewage to circularly flow through the water treatment flexible layer. Compared with theprior art, the pollution repairing method disclosed by the invention has the advantages that the pollutant eliminating efficiency is higher and the problem of secondary pollution is hardly consideredin the water treatment process.

Owner:上海城投上境生态修复科技有限公司

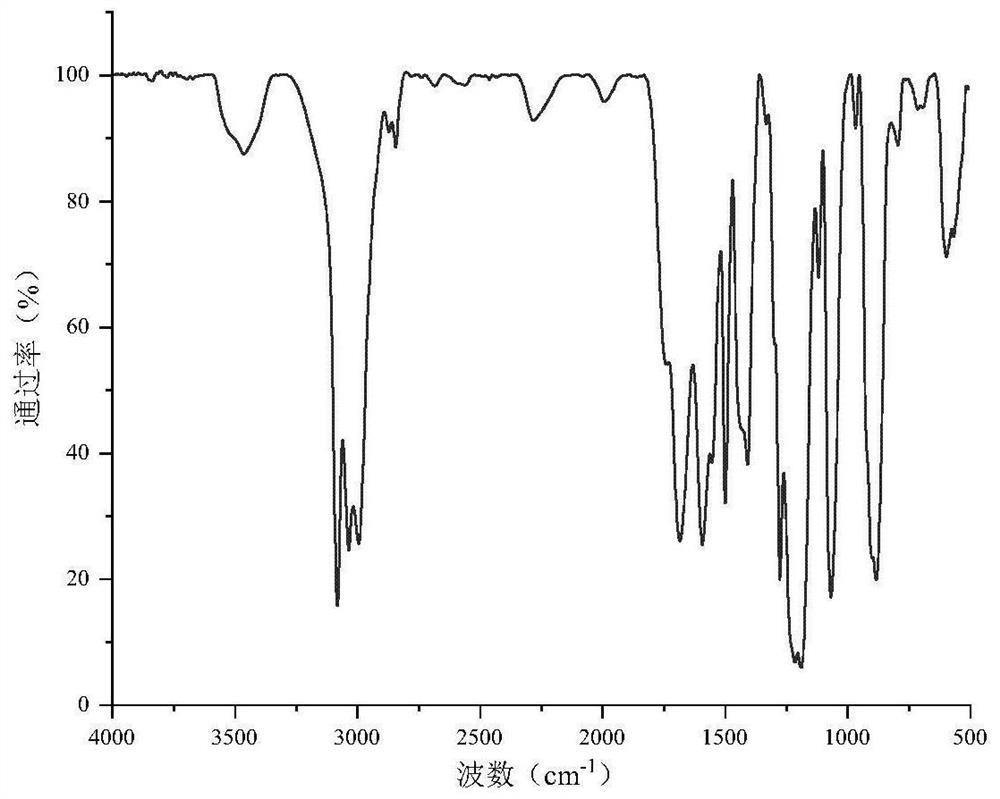

Starch type impregnating agent for alkali-free glass fibers

InactiveCN109608058AChange surface stateMeet the processing performance requirements of the subsequent processEtherBond properties

The invention discloses a starch type impregnating agent for alkali-free glass fibers. The impregnating agent is prepared from, by weight, 3-5 parts of corn starch,1-2 parts of triglyceride, 0.3-8 parts of fatty acid ester, 0.05-0.1 part of polyoxyethylene polyoxypropylene ether, 0.05-0.1 part of fatty acid polyoxyethylene amide, 0.1-1 part of a softening agent, 0.1-0.4 part of an antistatic agent, 0.3-0.6 part of modified epoxy resin, 0.05-0.12 part of a preservative and 0.0005-0.002 part of a defoaming agent. The impregnating agent improves the bonding property between yarn and matrix resinand the permeability of the resin.

Owner:LINZHOU GUANGYUAN NEW MATERIAL TECH

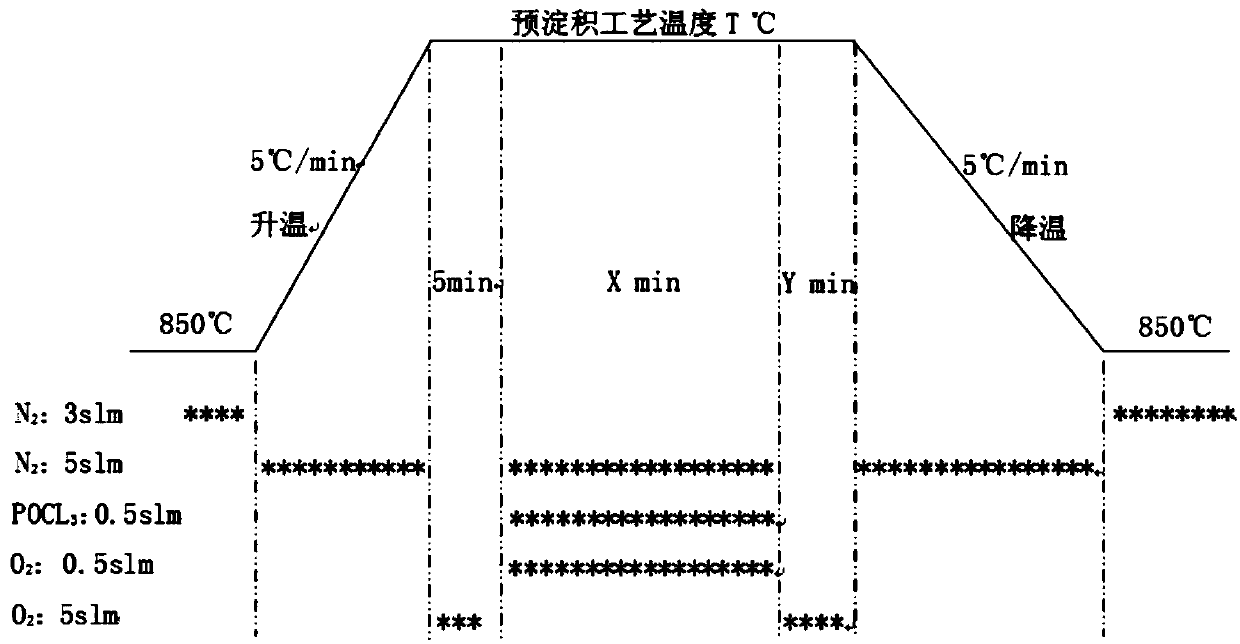

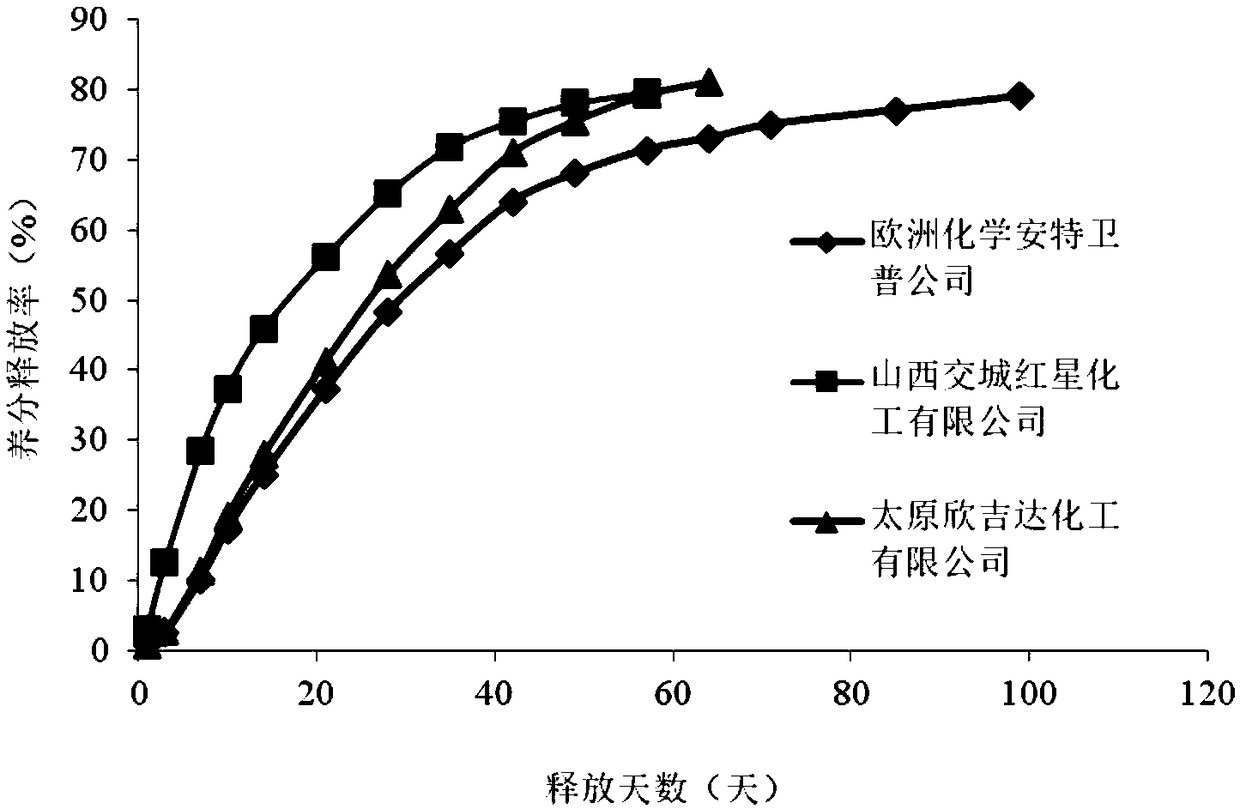

Polyurethane coated calcium ammonium nitrate and manufacturing method thereof

InactiveCN109438140AReduce intensityChange surface stateNitrate fertilisersLayered/coated fertilisersNuclear chemistryRaw material

The invention discloses a manufacturing method of polyurethane coated calcium ammonium nitrate and polyurethane coated calcium ammonium nitrate manufactured with the method. Particularly, the method comprises the following steps: placing calcium ammonium nitrate in a rotating drum for preheating; preparing a fertilizer surface treatment liquid and uniformly applying the fertilizer surface treatment liquid to the surface of preheated calcium ammonium nitrate to form a liquid film; performing programmed temperature rise; pre-mixing all the raw materials forming a polyurethane coating liquid, preheating and spraying the polyurethane coating liquid to the surface of calcium ammonium nitrate; performing rotating and cooling, and curing the polyurethane coating to obtain polyurethane coated calcium ammonium nitrate. The manufacturing method, which is provided by the technical scheme, of polyurethane coated calcium ammonium nitrate can improve surface defects and thermal stability of calciumammonium nitrate, so that obtained polyurethane coated calcium ammonium nitrate has higher integrity and lower initial dissolution rate.

Owner:上海永通生态工程股份有限公司

Chemical granulation processing method for quartz surface

A method for chemically and roughly treating a quartz surface overcomes the defects of the prior art in which the treatment to the quartz surface easily leads to damage and influences the size accuracy of the quartz product. The method is as below: at a normal temperature and a normal pressure, immersing a quartz product into a container filled with a treating fluid so as to undergo reaction after the surface of the quartz product is polished, taking out the quartz product after two-hour reaction, and immersing the quartz product into the treating fluid again so as to repeat the preceding reaction till the roughness Ra of the surface of the quartz product is equal to 1.5 micrometers to 4.5 micrometers after attachments on the surface of the quartz product is eliminated with deionized water. The treatment process has reasonable design, involves simple devices and is easy to be operated, and the obtained quartz product has uniform surface roughness which is free from the influence of the shape. During the participation in the CVD reaction, the crazing and the shedding of a deposited film on the quartz surface is effectively reduced so as to reduce the possibility of pollution to thereaction cavity, to remarkably improve the finished product rate and the production efficiency, and then further to prolong the service life of the quartz product, save time, reduce consumption and reduce production cost.

Owner:SHENYANG HANKE SEMICON MATERIALS

Manufacture method of pole of super capacitor

InactiveCN100550237CChange surface stateIncrease specific energyElectrolytic capacitorsElectrode carriers/collectorsMetal stripsMetal foil

This invention discloses a burr metal strip collector and its usage in a super capacitor, in which, a flexible active carbon plate is adhered on said burr metal foil with the thickness of 0.05~0.2mm and burr round hole or square hole in the gap of 0.5~2.0mm by vertical pressing or rolling to process an electrode of a super capacitor to increase the loading volume of the active carbon and alter the surface state of a collector.

Owner:SHANGHAI AOWEI TECH DEV

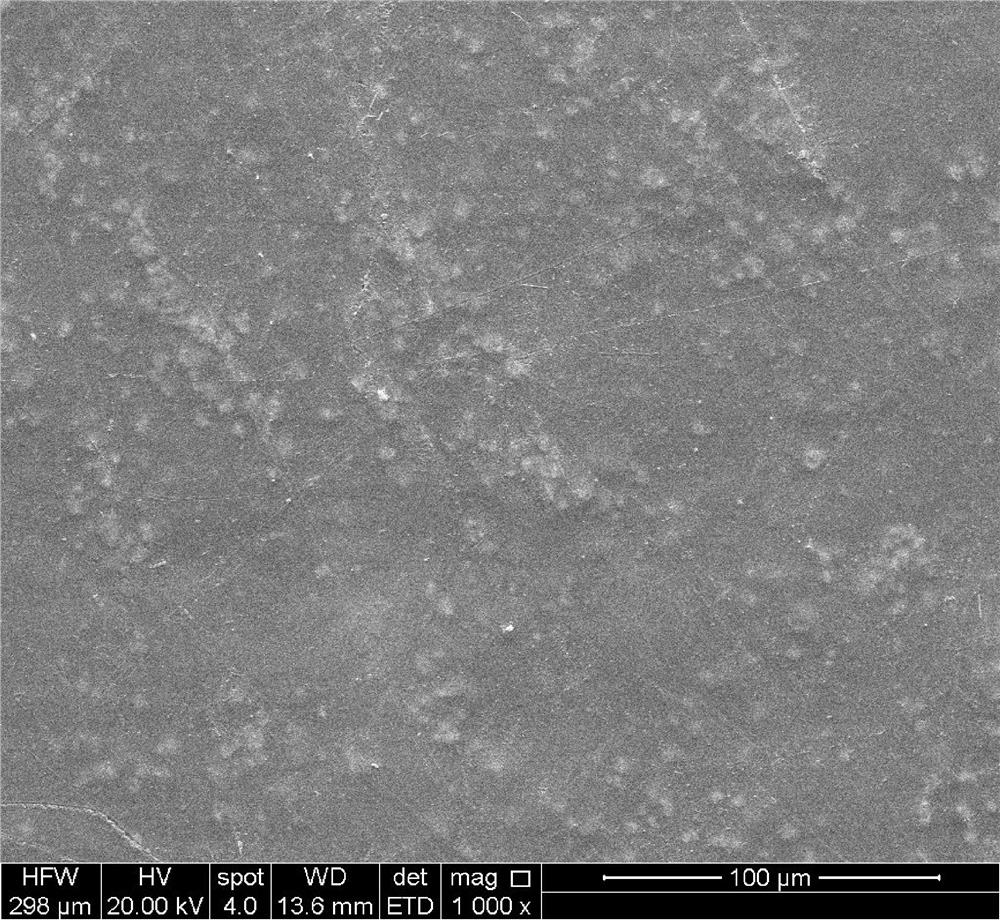

Preparation method of composite film layer on surface of rare earth magnesium alloy structural part

ActiveCN112251790AMeet assembly dimensional tolerance requirementsReduce electrophoresis voltageAnodisationElectrophoretic coatingsElectrolytic agentMicro arc oxidation

The invention discloses a preparation method of a composite film layer on the surface of a rare earth magnesium alloy structural part. The preparation method sequentially comprises the steps of oil removal, primary water washing, micro-arc oxidation, secondary water washing, electrophoresis, tertiary water washing and drying and curing. A micro-arc oxidation electrolyte is an aqueous solution containing sodium silicate, sodium fluoride, sodium hydroxide, graphene, Cu(NO3)2 and triethanolamine, electrical parameters of micro-arc oxidation are as follows: the positive current density is 5-15A / dm<2>, the negative current density is 2-3A / dm<2>, the positive duty ratio is 25-70%, the negative duty ratio is 40-50%, the positive frequency is 200-800Hz, the negative frequency is 300-500Hz, the positive and negative stages are both one stage, the micro-arc oxidation time is 10-20 min, electrophoresis liquid for electrophoresis is an aqueous solution containing acrylate, a delustering agent andcarbon black pigment, and electrical parameters of electrophoresis are as follows: the voltage is 50-80V, and the time is 10-30s; and through the coordination effect of micro-arc oxidation and electrophoresis, the composite film layer meeting the requirements of high hardness, high bonding strength and ultraviolet aging resistance at the same time can be prepared.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

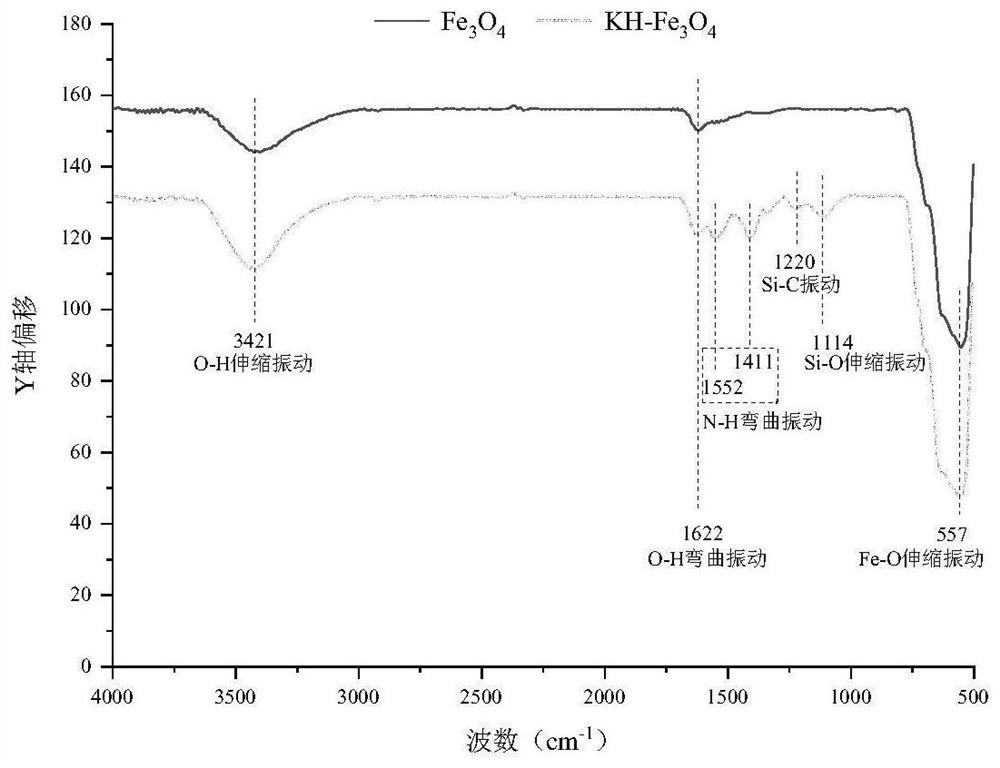

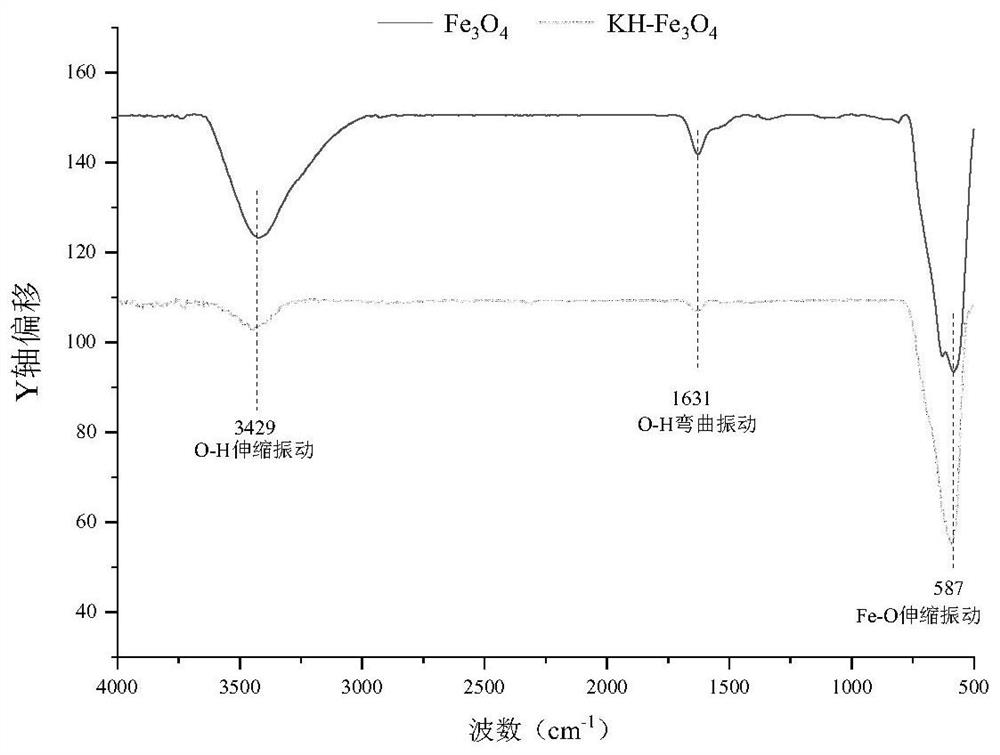

Magnetic powder activation method for magnetic asphalt, magnetic asphalt preparation method, asphalt plate pouring method and waterproof bonding layer paving method

ActiveCN113045235AReduce reunionEfficient modificationBridge structural detailsBridge erection/assemblyFiberBridge deck

The invention discloses a magnetic powder activation method for magnetic asphalt, a magnetic asphalt preparation method, an asphalt plate pouring method and a waterproof bonding layer paving method. Firstly, an ultrasonic device is adopted to achieve effective modification of a silane coupling agent in a base solution on the surface of magnetic powder so as to reduce agglomeration of magnetic powder particles in the preparation process of the magnetic asphalt, the magnetic powder with good dispersity is obtained, then the magnetic powder and the asphalt are mixed at different shearing rates and shearing time, the prepared magnetic asphalt is magnetized, and finally, fibers are embedded into a template for pouring, and the magnetic fiber asphalt plate capable of being used for paving the waterproof bonding layer of the steel bridge deck is prepared. The magnetic powder in the prepared magnetic asphalt is uniform in dispersion and free of agglomeration, the magnetic asphalt has high residual magnetism and coercive force, the bonding effect and deformation compliance between a waterproof bonding layer and a steel plate can be improved, the tensile strength of the magnetic asphalt can be improved through embedding of fibers, the service life is prolonged, and the magnetic fiber asphalt plate is simple in preparation method and low in transportation cost, and the pavement process is simple and convenient, and the method has important construction popularization significance.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +2

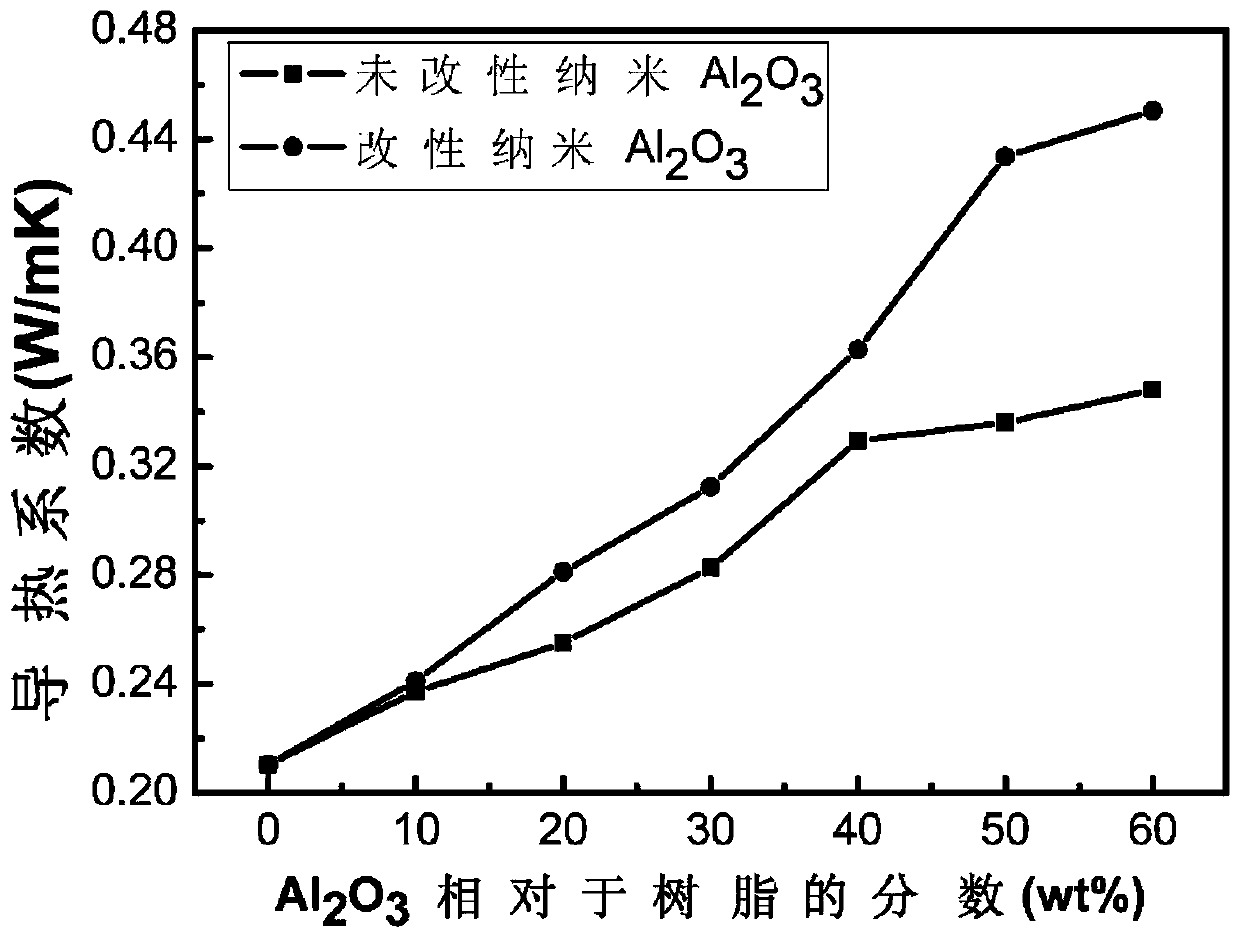

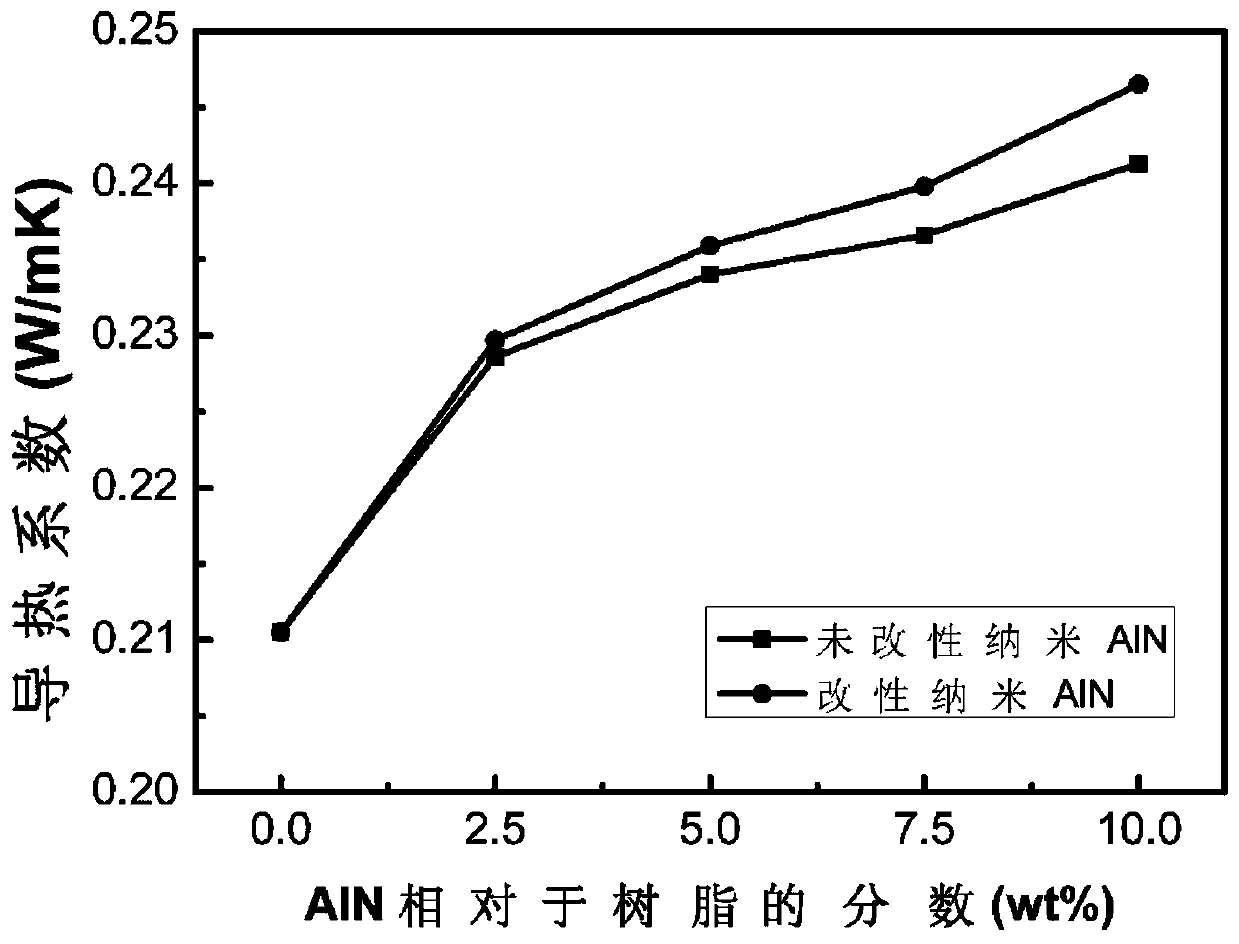

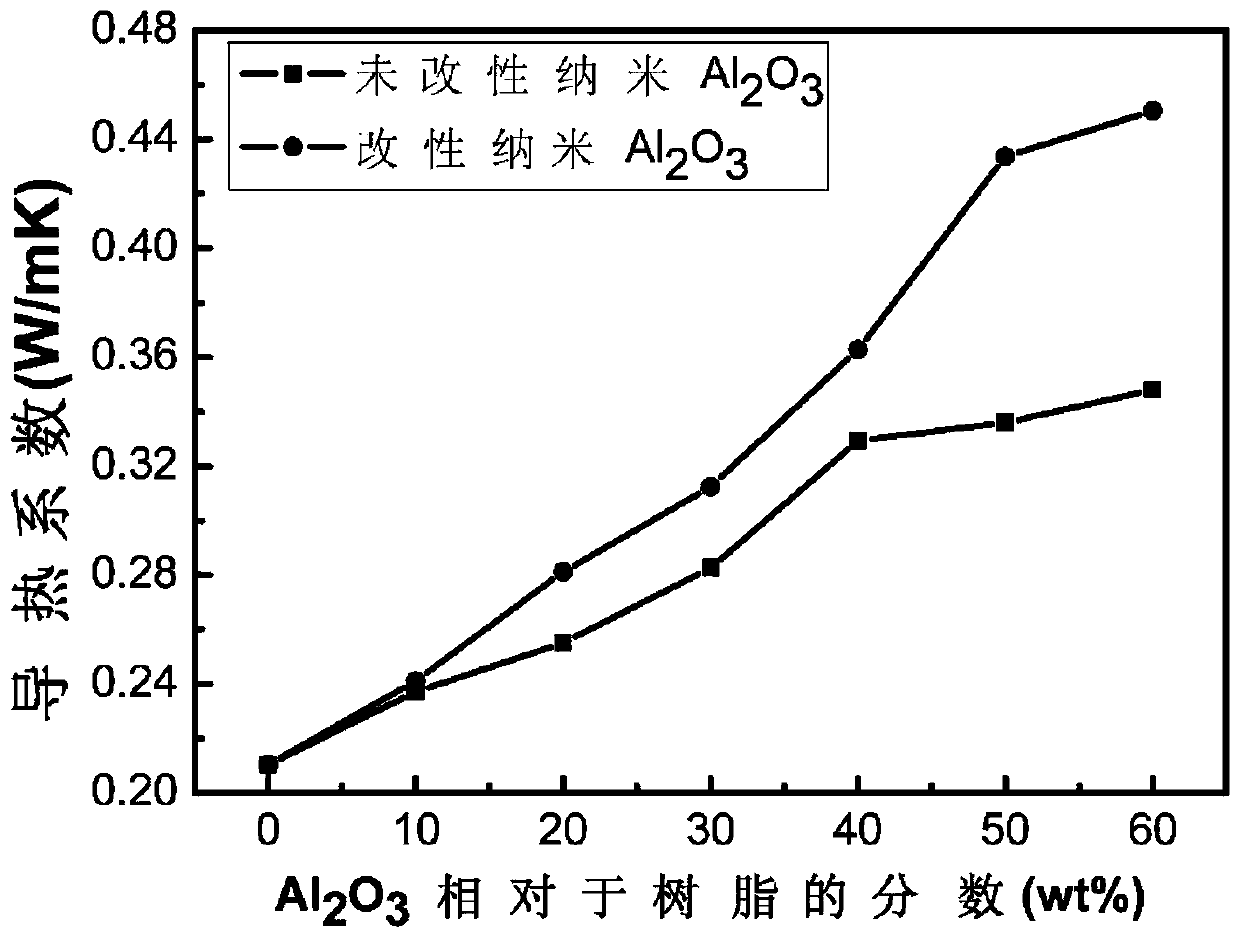

A kind of high thermal conductivity photocurable coating for optical fiber, and its preparation and application

ActiveCN107083159BImprove thermal conductivitySmall coefficient of thermal expansionCladded optical fibreAnti-corrosive paintsHeat conductingReaction temperature

The invention discloses a high-thermal-conductivity photocureable coating for an optical fiber and a preparation method and an application of the high-thermal-conductivity photocureable coating. The coating contains acrylate resin, vinyl silane coupling agent modified inorganic heat-conducting particles, an active diluent and a photoinitiator, wherein the vinyl silane coupling agent modified inorganic heat-conducting particles are 2.5wt%-60wt% of weight of the acrylate resin, the active diluent is 10wt%-50wt% of weight of the acrylate resin, and the photoinitiator is 1wt%-10wt% of weight of the acrylate resin. Compared with the prior art, by improving the type, proportion and corresponding preparation methods of substances of key constituents in the coating (including the design of integral process flow of the preparation method and the type and ratio of reaction raw materials, reaction temperature and time of each step), the problems that a coating layer formed after an existing optical fiber coating is solidified is low in heat conductivity coefficient and relatively high in thermal expansion coefficient can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

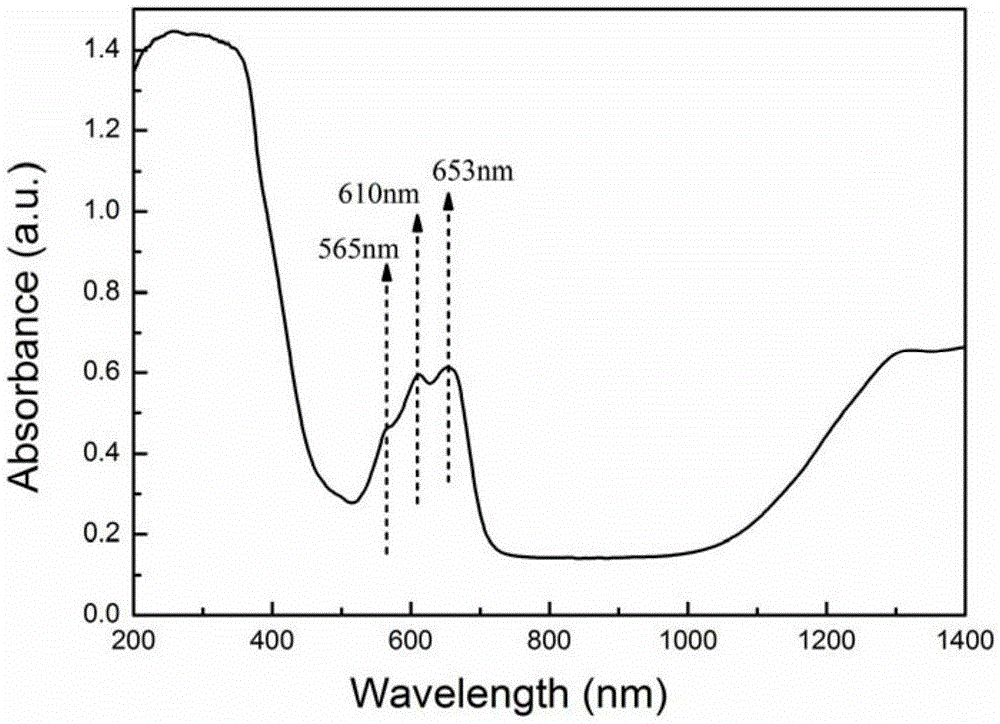

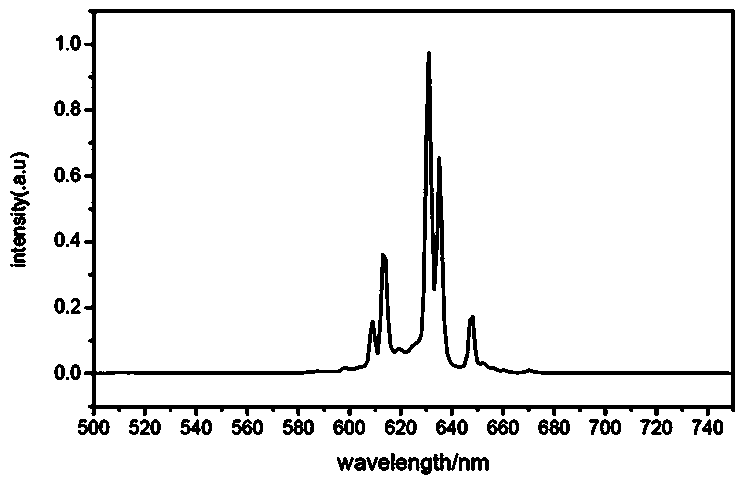

A kind of high temperature and high humidity resistant fluoride red phosphor and preparation method thereof

ActiveCN106479485BPromote crystallizationGood dispersionLuminescent compositionsPolyethylene glycolSolid particle

The invention provides a high-temperature-resistant and high-humidity-resistant fluoride red fluorescent powder and a preparation method thereof. The fluorescent powder has a general chemical formula of KmAnM1-xF6: xMn<4+>. In the general chemical formula, A is one or two selected from the group consisting of Cu, Ba and Zn; M is at least one selected from the group consisting of Ti, Si and Ge; m + 2n are equal to 2; n is no less than 0.05 and no more than 0.2; m is no less than 1.6 and no more than 1.9; x is more than 0 and less than 0.2; and the surface of the fluorescent powder is coated with a mixture of potassium silicate, carboxymethyl cellulose sodium and polyethylene glycol. The fluorescent powder provided by the invention can be effectively excited by light with the excitation wavelength being in a range of 300 to 500 nm, so red light with a peak wavelength of 610 to 650 nm and a half-peak breadth of only 2 to 9 nm is generated, and high color purity is obtained. The preparation method provided by the invention has simple flow, can prepare target products at low temperature and under normal pressure, and facilitates to large-scale industrial production; and a special coating technology is adopted in the invention, and a coating reagent is utilized to change the surface state of fluorescent powder particles, so the problem of agglomeration of solid particles can be effectively solved, and a fluorescent powder product with good dispersion properties and high-temperature-resistant and high-humidity-resistant performances can be obtained.

Owner:HEBEI LIFU CHEM TECH

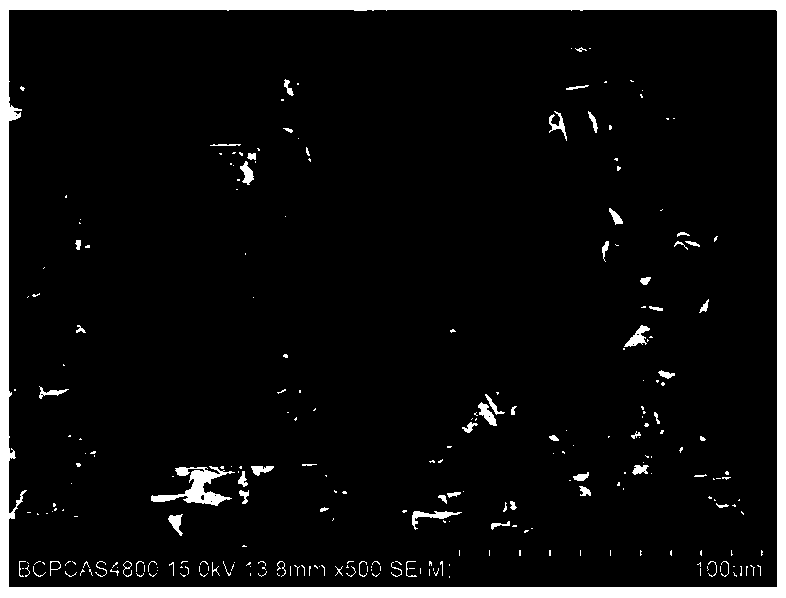

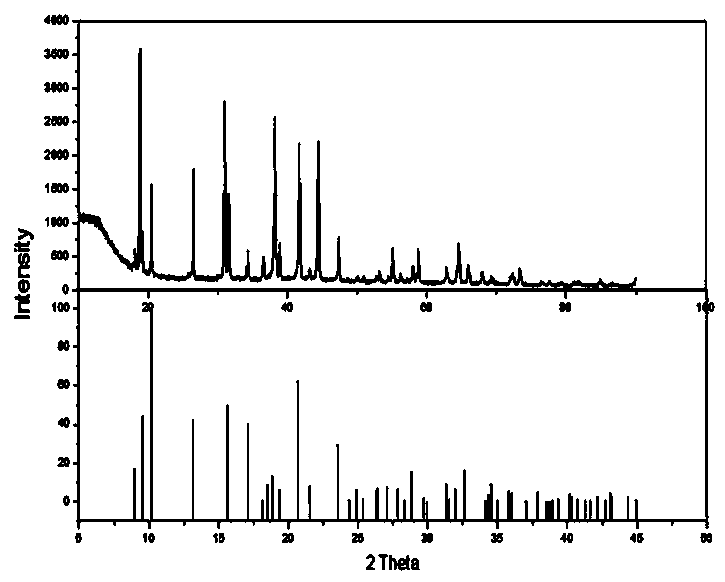

A sol-gel preparation method of cobalt-doped zinc oxide nanorods

ActiveCN105314672BImprove adsorption capacityAdjust electronic energy state structureMaterial nanotechnologyZinc oxides/hydroxidesAir atmosphereReaction temperature

The invention discloses a method for preparing cobalt-doped zinc oxide nanorods through sol-gel. The method comprises the steps of dissolving dihydrate zinc acetate and tetrahydrate cobaltous acetate into ethylene glycol monomethyl ether according to the stoichiometric ratio of Zn<1-x>Co<x>O, stirring the mixture uniformly, and obtaining a mixed solution; dropwise adding ethanolamine to the mixed solution, conducting a reaction under the condition that the mixture is stirred at the temperature of 60-80 DEG C, cooling the mixture naturally to the room temperature after the reaction is ended, and obtaining clear cobalt-doped zinc oxide precursor sol; drying the clear cobalt-doped zinc oxide precursor sol, obtaining dried gel, then making the dried gel be subjected to a heat treatment process in the air atmosphere, and obtaining the clear cobalt-doped zinc oxide nanorods. According to the method, the cobalt-doped zinc oxide nanorods are prepared through a multicomponent uniform reaction sol-gel method, and the method has the advantages that the process is simple, the reaction temperature is low, the cost is low, the test process is easy to control, the product crystallinity degree is high, and the crystalline phase is pure, and the obtained clear cobalt-doped zinc oxide nanorods have ferromagnetism at the room temperature.

Owner:XIAN TECH UNIV

Nano carbon tube composite high-energy accumualtor-separator gate

The invention relates to the slab lattice of high-energy accumulator made of the composite nanometer carbon tube. The ingredient of the slab lattice includes nanometer carbon tube, carbon fiber and silicon nitride. With the said ingredient being mixed and with 107 floor glue being added and mixed evently, die stamping the said mixed material obtains the roughts. The agglutinated slab lattices areobtained by heat drying, agglutinating the roughs then cooling down the roughs slowly. Lead plaster in 3 days screen mesh is coated on the slab lattice. After 20-25 hours, the slab lattice can be used to assemble the accumulator.

Owner:乌日根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com