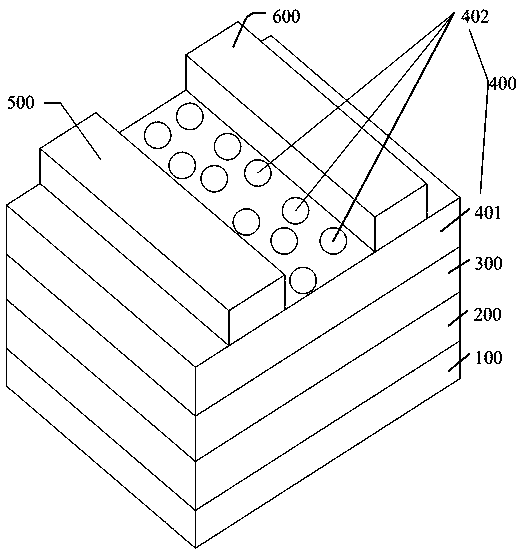

Transistor type formaldehyde sensor and manufacturing method thereof

A technology of formaldehyde sensor and manufacturing method, which is applied in the field of transistor-type formaldehyde sensor and its manufacture, can solve the problems of formaldehyde sensor stability and poor selectivity, and achieve the effect of solving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

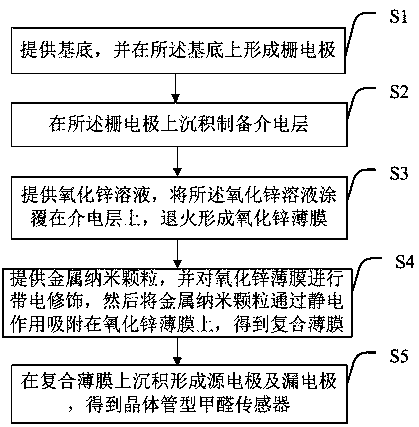

[0052] On the flexible PDMS substrate, silver is thermally evaporated through a mask to form a gate electrode, and a 30-nanometer-thick aluminum oxide dielectric layer is prepared on the gate electrode by atomic layer deposition;

[0053] Dissolve zinc oxide in ammonium hydroxide and refrigerate for 5 hours, then add deionized water and hydroxides of lithium, sodium, and potassium to the zinc oxide solution. The molar ratio of alkali metal hydroxide and zinc oxide added here is The ratio is 0.1:1 to obtain the zinc oxide thin film precursor solution. The zinc oxide film precursor solution is spin-coated on the dielectric layer, the spin-coating speed is 3000rpm, the time is 30s, annealing at 200°C for 0.5h, and the nano-zinc oxide film is obtained;

[0054] Heat tetrachloroauric acid solution to 100°C, add sodium citrate, here the molar ratio of sodium citrate and tetrachloroauric acid is 3.78:1, the reaction continues for 30 minutes, and finally the solution is cooled to room...

Embodiment 2

[0057] On the flexible PDMS substrate, silver is thermally evaporated through a mask to form a gate electrode, and a 30-nanometer-thick aluminum oxide dielectric layer is prepared on the gate electrode by atomic layer deposition;

[0058] Dissolve zinc oxide in ammonium hydroxide and refrigerate for 5 hours, then add deionized water and hydroxides of lithium, sodium, and potassium to the zinc oxide solution. The molar ratio of alkali metal hydroxide and zinc oxide added here is The ratio is 0.01:1 to obtain the zinc oxide thin film precursor solution. The zinc oxide film precursor solution is spin-coated on the dielectric layer, the spin-coating speed is 3000rpm, the time is 30s, annealing at 200°C for 0.5h, and the nano-zinc oxide film is obtained;

[0059] At room temperature, mix and stir sodium citrate and silver nitrate, the molar ratio of sodium citrate and silver nitrate is 3.78:1, then immediately add sodium borohydride, the reaction continues for 20 minutes, and final...

Embodiment 3

[0062] On the flexible PDMS substrate, silver is thermally evaporated through a mask to form a gate electrode, and a 30-nanometer-thick aluminum oxide dielectric layer is prepared on the gate electrode by atomic layer deposition;

[0063] Dissolve zinc oxide in ammonium hydroxide and refrigerate for 5 hours, then add deionized water and hydroxides of lithium, sodium, and potassium to the zinc oxide solution. The molar ratio of alkali metal hydroxide and zinc oxide added here is The ratio is 0.15:1 to obtain the zinc oxide thin film precursor solution. The zinc oxide film precursor solution is spin-coated on the dielectric layer, the spin-coating speed is 3000rpm, the time is 30s, annealing at 200°C for 0.5h, and the nano-zinc oxide film is obtained;

[0064] At room temperature, mix and stir sodium citrate and platinum quaternary salt, the molar ratio of sodium citrate and platinum quaternary salt is 3.78:1, then add sodium borohydride immediately, the reaction continues for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com