Tunable optical absorber

A technology of light absorption and thin film, which is applied in the field of absorbers, can solve the problems of slow response speed of liquid crystal, and achieve the effect of fast response speed and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

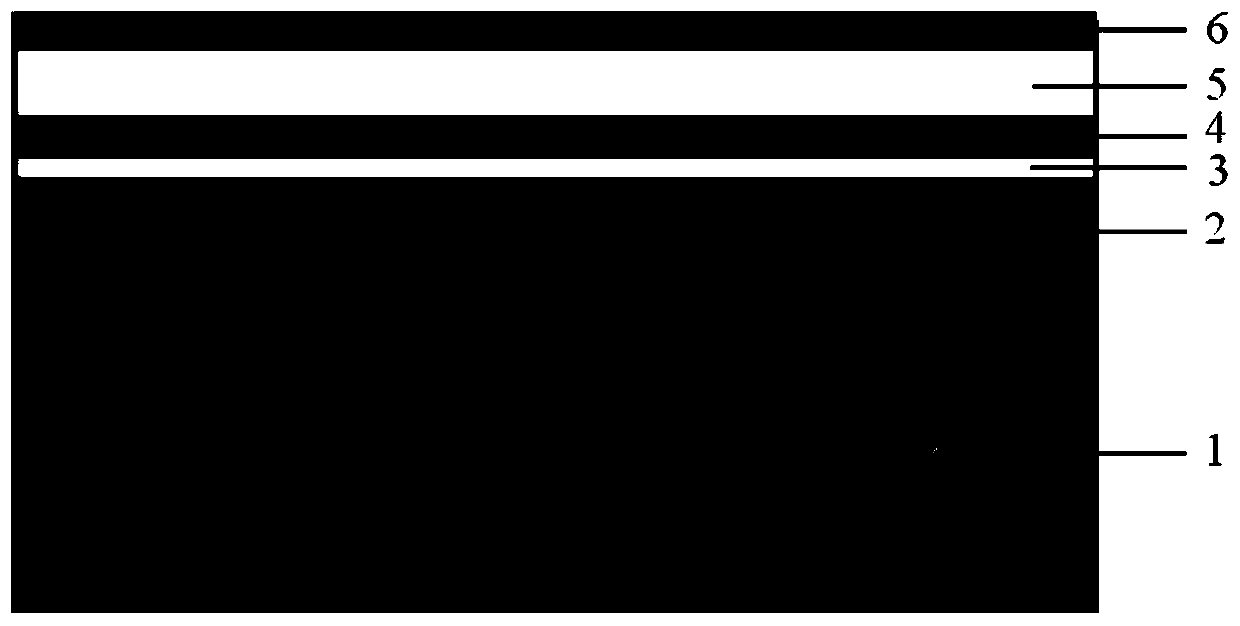

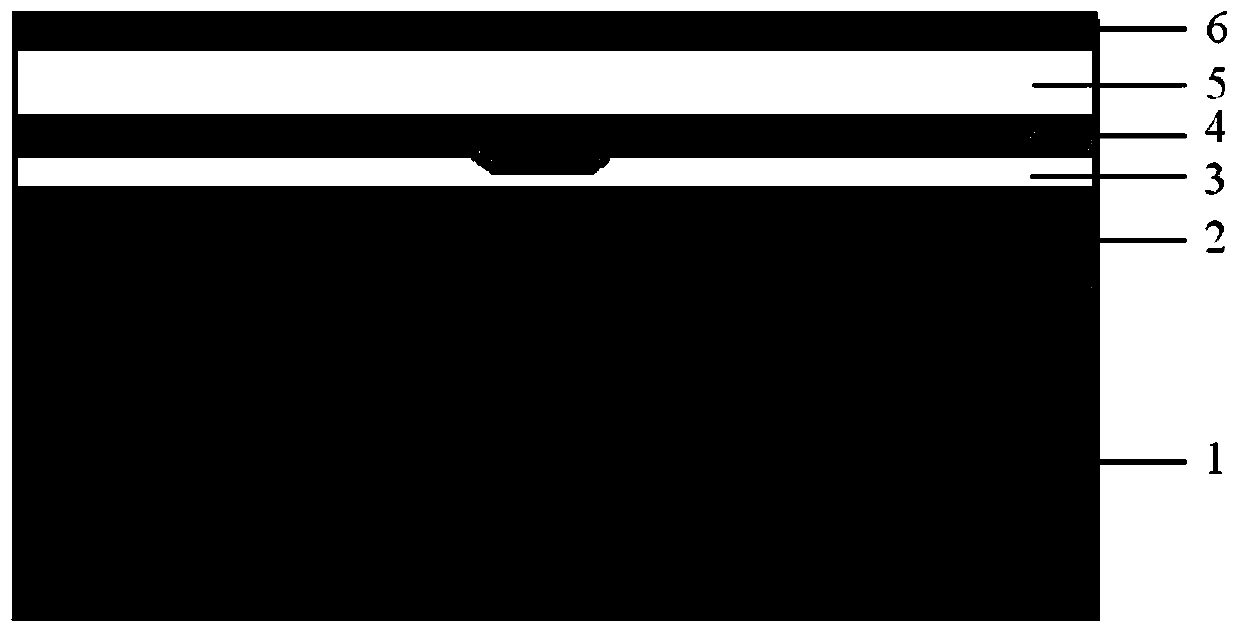

[0019] refer to figure 1 with figure 2 An embodiment of a tunable optical absorber of the present invention is further described.

[0020] In order to achieve the above object, the present invention provides the following technical solutions: a tunable optical absorber, including a substrate 1, the surface of the substrate 1 is deposited in sequence with a lower metal silver film 2, a lower silicon dioxide dielectric film 3, and an n-type antimony film. Indium thin film 4 , upper silicon dioxide dielectric thin film 5 and upper metallic silver thin film 6 .

[0021] Since the resonant frequency of the MIM structure device depends on the dielectric constant, refractive index and thickness of the dielectric material between the two metal materials and other characteristic parameters, the present invention uses the substrate 1 material as the substrate, and its upper surface is a polished surface. , sputtering and other physical vapor deposition techniques deposit the lower me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com