Semiconductor device and mfg. method thereof

A technology of semiconductors and manufacturing methods, which is applied in the field of semiconductor device manufacturing, can solve problems such as complex process procedures, and achieve the effects of avoiding mask misalignment and suppressing product rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

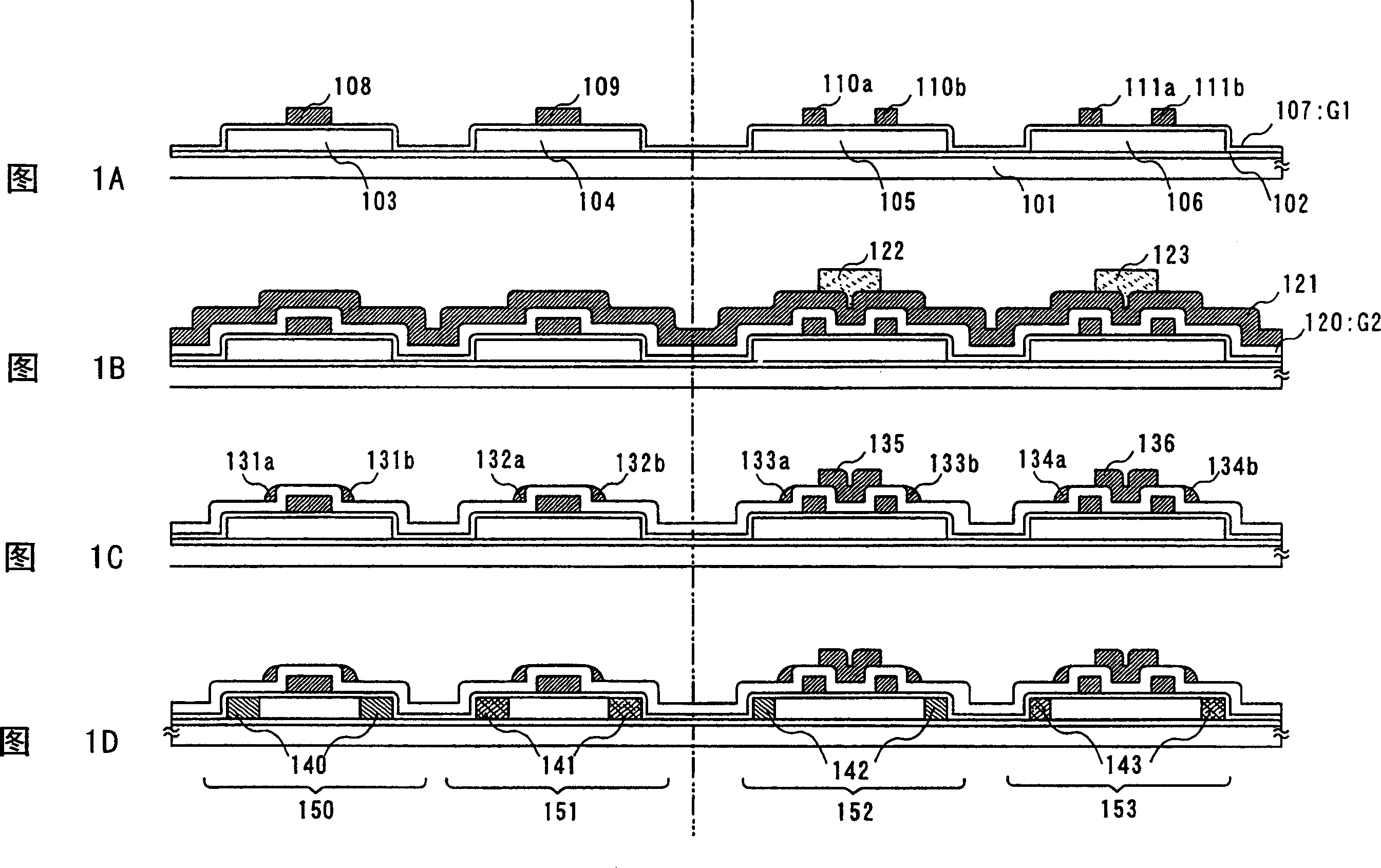

[0106] Refer below Figure 5 A method of fabricating a liquid crystal display device using an active matrix substrate having a functional circuit area and a pixel area is described.

[0107] The structure of an active matrix liquid crystal display device using TFT as a switching element is as follows: the substrate (active matrix substrate) where the pixel electrodes are arranged in a matrix is opposite to the opposite substrate on which the counter electrode is formed. a liquid crystal layer. A spacer or the like is used to control the distance between the two substrates at a certain interval. The outer periphery of the pixel portion seals the liquid crystal layer between the substrates with a sealing material.

[0108] Hereinafter, a method of fabricating an active matrix substrate having a functional circuit area and a pixel area will be described. The structure of the TFT described in Embodiment Mode 1 is applicable to this embodiment. because Figure 5 The n-channel ...

Embodiment 2

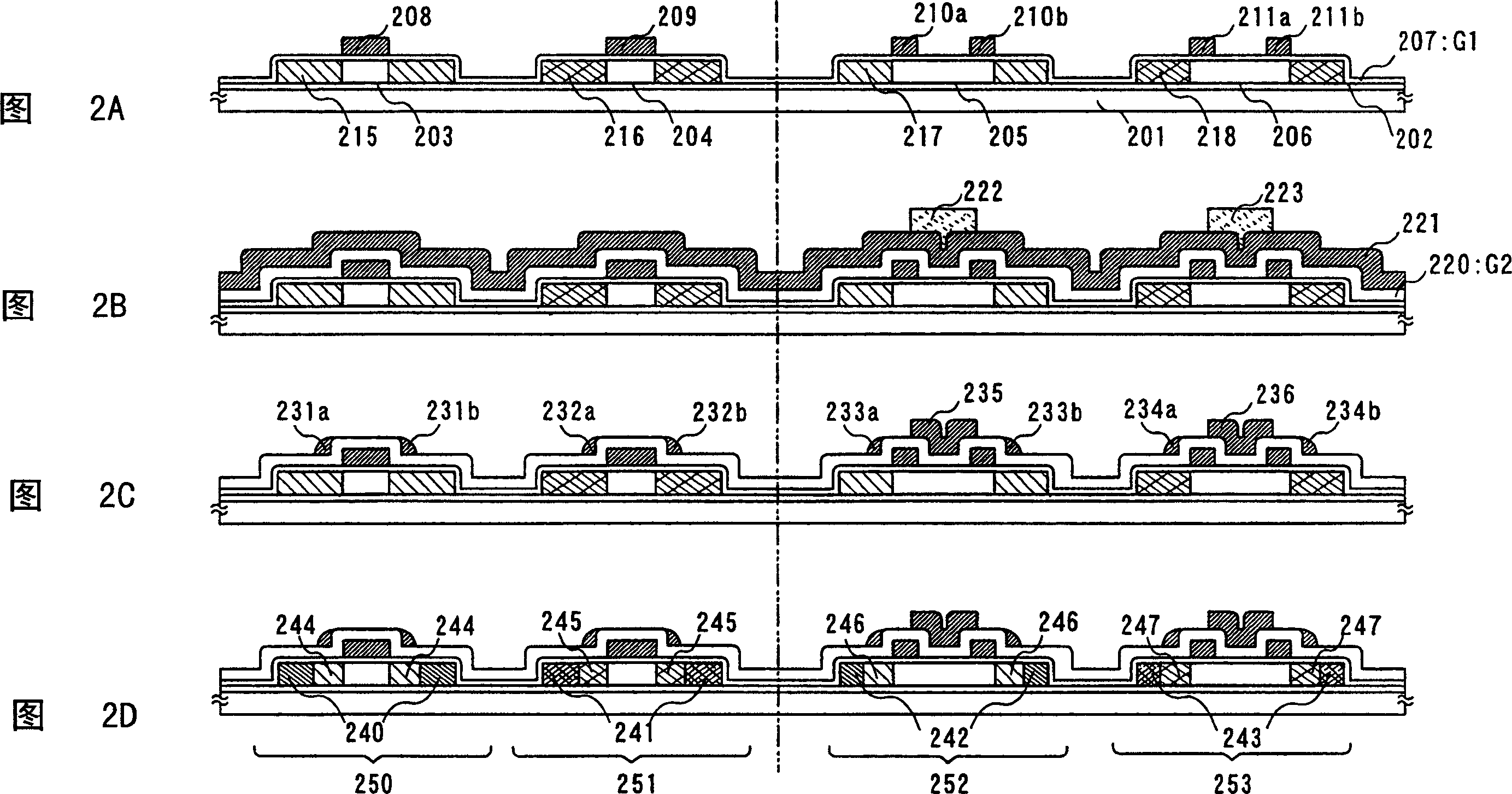

[0135] Refer to the attached Image 6 A method of fabricating an EL display device fabricated using an active matrix substrate having a pixel portion and a functional circuit portion will be described.

[0136] An EL display device using TFTs as switching elements is composed of a substrate (active matrix substrate) and a sealing member on which pixel electrodes are arranged in a matrix, and a counter electrode is formed on the EL layer on the pixel electrodes. The substrate and seal are sealed by an adhesive material.

[0137] Hereinafter, a fabrication example of an active matrix substrate will be described.

[0138]According to the same steps as in Embodiment 1, an n-channel TFT 640 and a p-channel TFT 641 are formed in the functional circuit part, and a current control TFT 642 made of a p-channel TFT and a current control TFT 642 made of an n-channel TFT are formed in the pixel part. The switch TFT643 made of TFT. Note that the TFT described in Embodiment Mode 1 is appl...

Embodiment 3

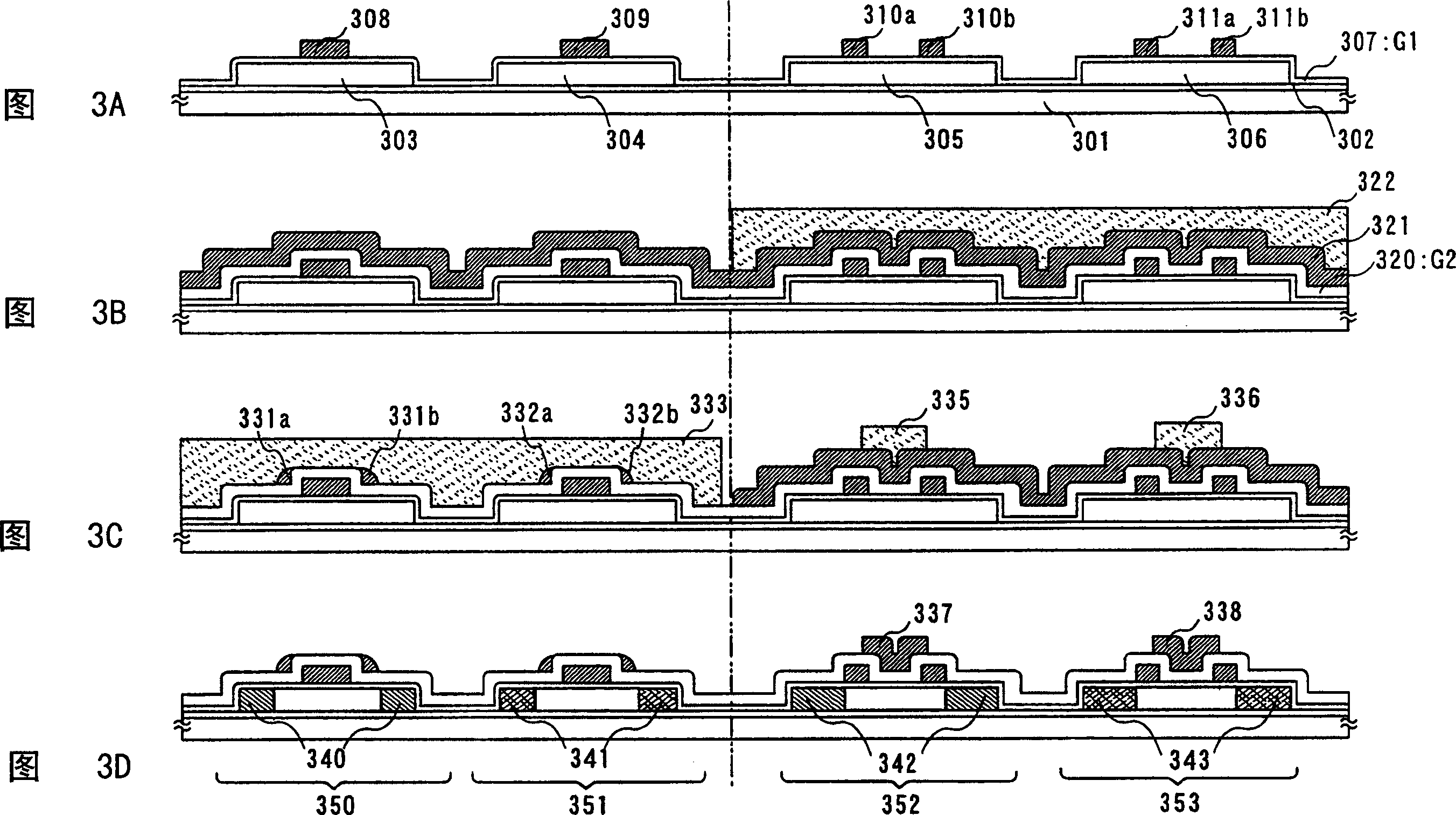

[0160] In this example, reference will be made to the attached Figures 7A-7D An example of a manufacturing method of a semiconductor layer in which the TFTs described in Embodiment Mode 1 to Embodiment Mode 4, Example 1 and Example 2 are applied to the semiconductor layer will be described. In this embodiment, a continuous oscillating laser beam scans an amorphous silicon film formed on an insulating surface, thereby crystallizing it.

[0161] Such as Figure 7AAs shown, a base layer 702 including a silicon oxynitride film with a thickness of 100 nm is formed on a glass substrate 701 . On the base layer 702, an amorphous silicon film 703 is formed to a thickness of 54 nm by the plasma CVD method.

[0162] Next, if Figure 7B As shown, the semiconductor layer is irradiated with a laser beam. The laser beam irradiated on the semiconductor layer is from Nd:YVO 4 The continuous beam emitted by the laser is the second harmonic (532nm) obtained by the wavelength conversion ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com