Polyurethane coated calcium ammonium nitrate and manufacturing method thereof

A technology of calcium ammonium nitrate and manufacturing method, applied in nitrate fertilizer, layered/coated fertilizer, nitrogen fertilizer, etc., can solve the problem that the coating material cannot be evenly distributed, the controlled-release calcium ammonium nitrate product is few, and the adhesion of coating material To maintain the effective nitrogen content, reduce energy consumption, and avoid the reduction of particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

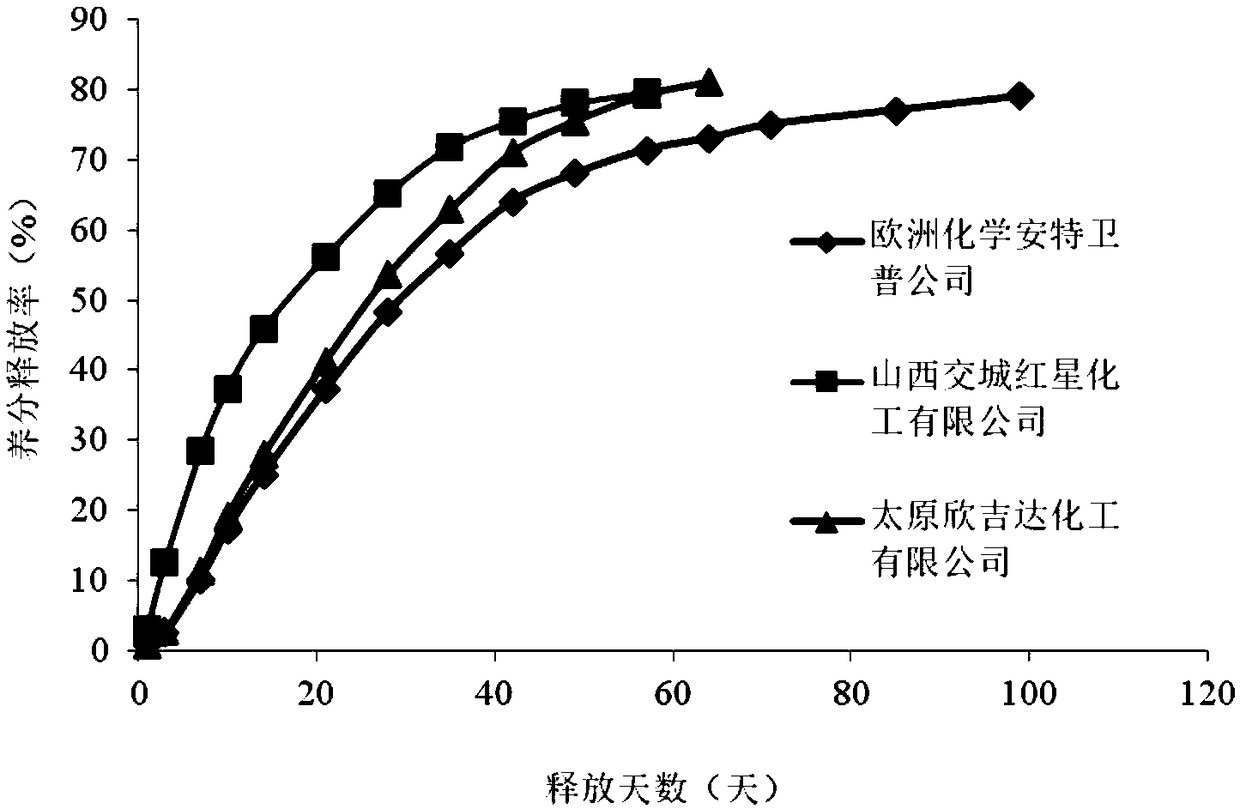

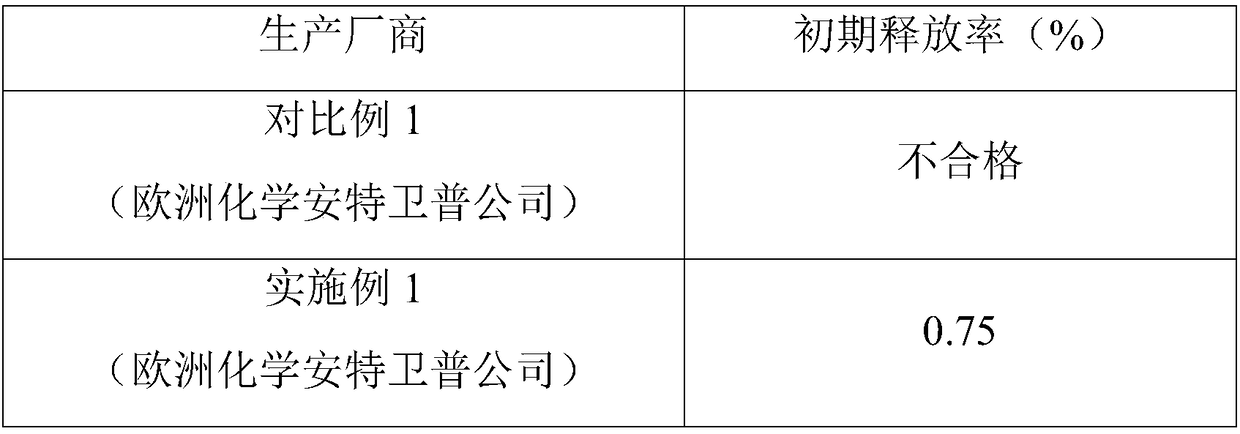

Embodiment 1

[0033] Start the sugar-coating machine, adjust the speed of the sugar-coating machine to 22 rpm, and turn on the electric heating switch. Weigh 1 kg of 2-4 mm calcium ammonium nitrate produced by European Chemical Antwerp Company, preheat it in the fluidized state in the sugar coating machine, and test the surface temperature of the fertilizer with an infrared thermometer. When it reaches 40 ° C, it will be saturated for six Magnesium nitrate hydrate was sprayed onto the particle surface, and the temperature was programmed to rise at 5°C as an interval, and each interval lasted for 5 minutes until the temperature rose to 70°C. At this time, hot air at 60-70° C. is passed through for drying, and the drying time is 15 minutes. Then spray the polyurethane coating solution that was mixed and preheated to 80° C. on the surface of the fertilizer, including: 8.22 g of polymethylene polyphenyl isocyanate, 6.21 g of soybean oil, and 1.00 g of dibutyl phthalate. Adjust the rotation spe...

Embodiment 2

[0035] Start the sugar-coating machine, adjust the speed of the sugar-coating machine to 22 rpm, and turn on the electric heating switch. Weigh 1kg of 2-4mm calcium ammonium nitrate produced by Shanxi Jiaocheng Hongxing Chemical Co., Ltd., preheat it in the fluidized state in the sugar coating machine, and test the surface temperature of the fertilizer with an infrared thermometer. When it reaches 40°C , spray saturated magnesium nitrate hexahydrate onto the surface of the particles, program temperature rise, 5°C as an interval, each interval lasts 5 minutes, until the temperature rises to 70°C. At this time, hot air at 60-70° C. is passed through for drying, and the drying time is 15 minutes. Then spray the polyurethane coating solution that was mixed and preheated to 80° C. on the surface of the fertilizer, including: 8.22 g of polymethylene polyphenyl isocyanate, 6.21 g of soybean oil, and 1.00 g of dibutyl phthalate. Adjust the rotation speed to 35 rpm, roll for 7 minutes...

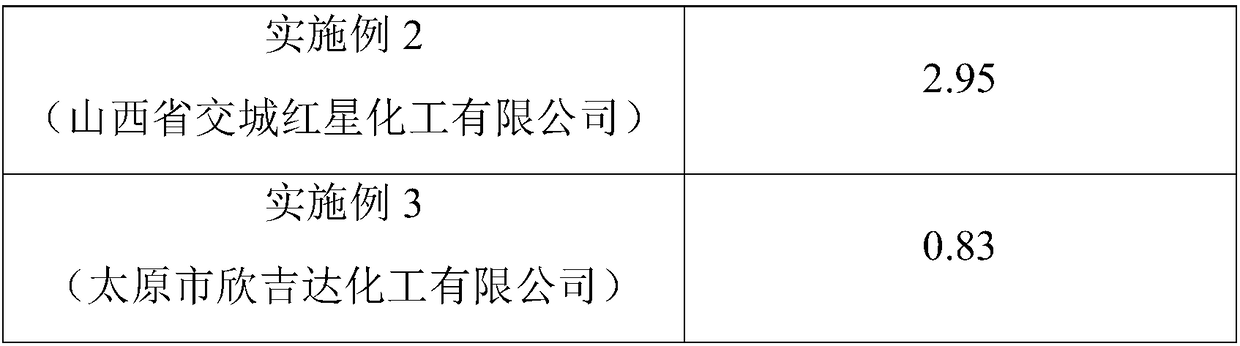

Embodiment 3

[0037]Start the sugar-coating machine, adjust the speed of the sugar-coating machine to 22 rpm, and turn on the electric heating switch. Weigh 1kg of 2-4mm calcium ammonium nitrate produced by Taiyuan Xinjida Chemical Co., Ltd., preheat it in the fluidized state in the sugar coating machine, and test the surface temperature of the fertilizer with an infrared thermometer. When it reaches 40°C , spray saturated magnesium nitrate hexahydrate onto the surface of the particles, program temperature rise, 5°C as an interval, each interval lasts 5 minutes, until the temperature rises to 70°C. At this time, hot air at 60-70° C. is passed through for drying, and the drying time is 15 minutes. Then spray the polyurethane coating solution that was mixed and preheated to 80° C. on the surface of the fertilizer, including: 8.22 g of polymethylene polyphenyl isocyanate, 6.21 g of soybean oil, and 1.00 g of dibutyl phthalate. Adjust the rotation speed to 35 rpm, roll for 7 minutes, turn off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com