Method for preparing cobalt-doped zinc oxide nanorods through sol-gel

A zinc oxide nanorod, zinc oxide technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problem of difficult synthesis control by hydrothermal method, high reaction temperature, and doping concentration by co-deposition method. Low problems, to achieve the effects of easy control of the experimental process, low reaction temperature, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

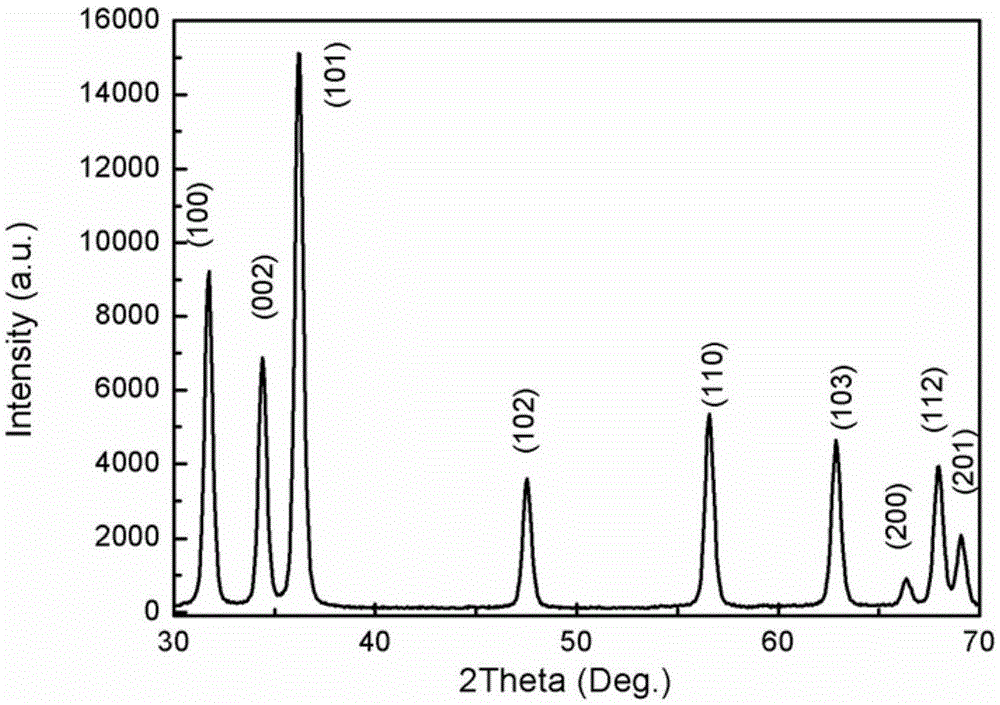

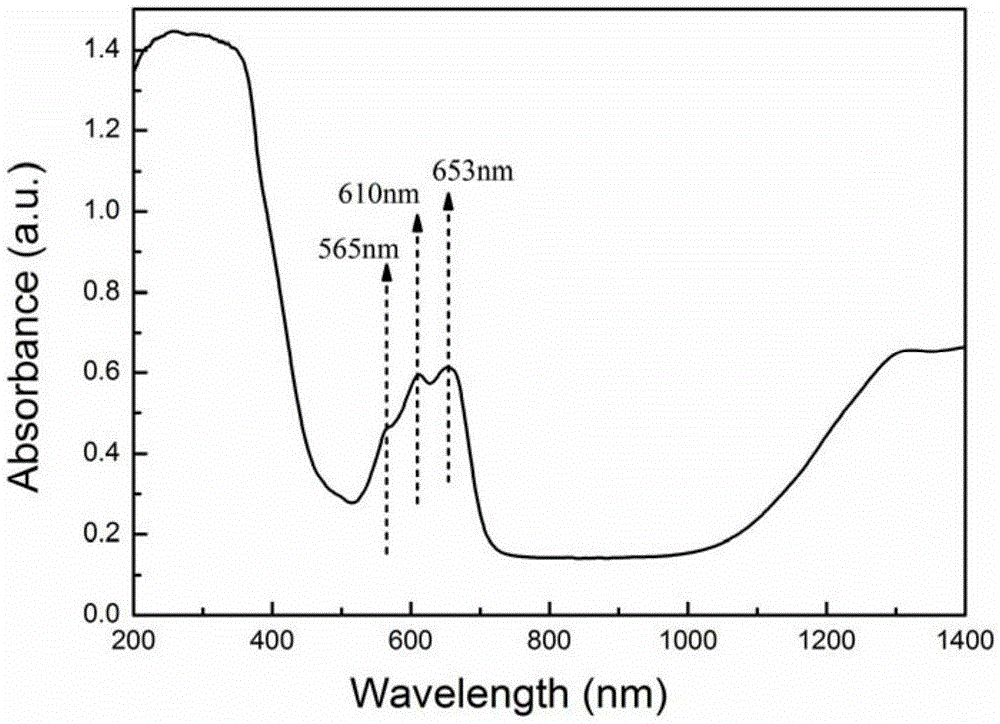

[0032] 1) According to Zn 0.99 co 0.01 For the stoichiometric ratio of O, dissolve zinc acetate dihydrate and cobalt acetate tetrahydrate in ethylene glycol methyl ether, and magnetically stir at room temperature to obtain a mixed solution; gradually add ethanolamine to the mixed solution, and then keep the temperature at 60°C Magnetically stirred for 2 hours, then naturally cooled to room temperature to obtain a clear cobalt-doped zinc oxide precursor sol, and the concentration of the precursor sol was adjusted to 0.7mol / L by adding ethylene glycol methyl ether; wherein, ethanolamine and Zn, Co metal The total molar ratio of ions is 5:1;

[0033] 2) Pour the clarified cobalt-doped zinc oxide precursor sol into a crucible, put it in a drying oven, and dry and dehydrate it at 100°C for 24 hours. After the xerogel is formed, perform a heat treatment process in a muffle furnace under an air atmosphere. Specifically The process is as follows: first keep warm at 300°C for 30 minu...

Embodiment 2

[0036] 1) According to Zn 0.995 co 0.005 For the stoichiometric ratio of O, dissolve zinc acetate dihydrate and cobalt acetate tetrahydrate in ethylene glycol methyl ether, and magnetically stir at room temperature to obtain a mixed solution; gradually add ethanolamine to the mixed solution, and then keep the temperature at 60°C Magnetically stirred for 2 hours, then naturally cooled to room temperature to obtain a clear cobalt-doped zinc oxide precursor sol, and the concentration of the precursor sol was adjusted to 0.7mol / L by adding ethylene glycol methyl ether; wherein, ethanolamine and Zn, Co metal The total molar ratio of ions is 3:1;

[0037] 2) Pour the clarified cobalt-doped zinc oxide precursor sol into a crucible, put it in a drying oven, and dry and dehydrate it at 120°C for 24 hours. After the xerogel is formed, perform a heat treatment process in a muffle furnace under an air atmosphere. Specifically The steps are as follows: first keep the temperature at 250°C f...

Embodiment 3

[0040] 1) According to Zn 0.9 co 0.1 For the stoichiometric ratio of O, dissolve zinc acetate dihydrate and cobalt acetate tetrahydrate in ethylene glycol methyl ether, and magnetically stir at room temperature to obtain a mixed solution; gradually add ethanolamine dropwise to the mixed solution, and then keep the temperature at 60°C Magnetically stirred for 2 hours, then naturally cooled to room temperature to obtain a clear cobalt-doped zinc oxide precursor sol, and the concentration of the precursor sol was adjusted to 0.7mol / L by adding ethylene glycol methyl ether; wherein, ethanolamine and Zn, Co metal The total molar ratio of ions is 4:1;

[0041] 2) Pour the clarified cobalt-doped zinc oxide precursor sol into a crucible, put it in a drying oven, and dry and dehydrate it at 150°C for 24 hours. After the xerogel is formed, perform a heat treatment process in a muffle furnace under an air atmosphere. Specifically The method is to first keep the temperature at 400°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com