Manufacture method of pole of super capacitor

A technology for supercapacitors and manufacturing methods, applied in capacitors, electrolytic capacitors, electrochemical generators, etc., can solve the problems of activated carbon falling off and the inability to adjust the active material of single-chip electrodes, etc., achieve small leakage current, long life, and increase specific energy and the effect of the self-discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

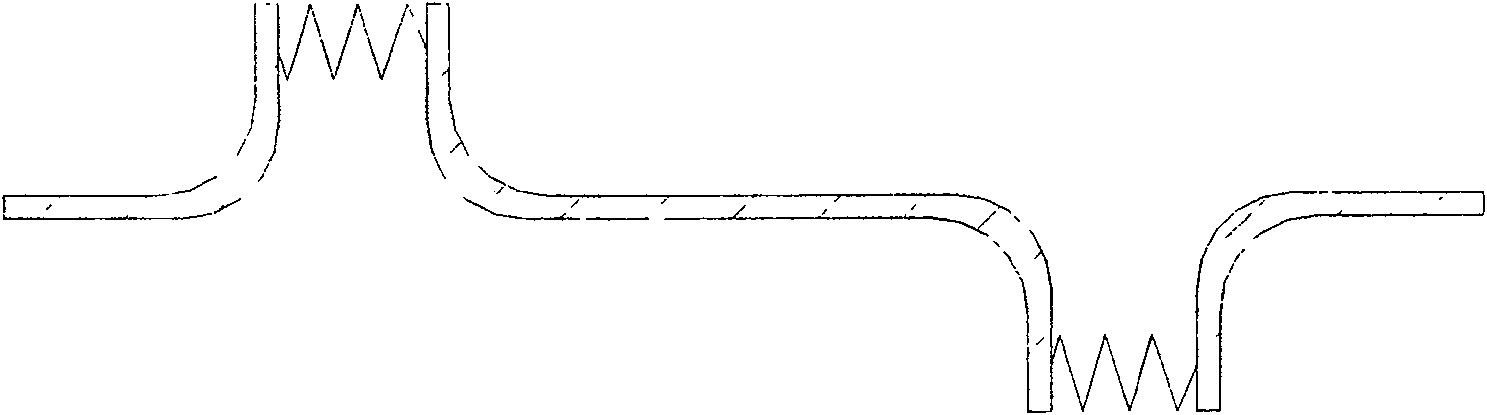

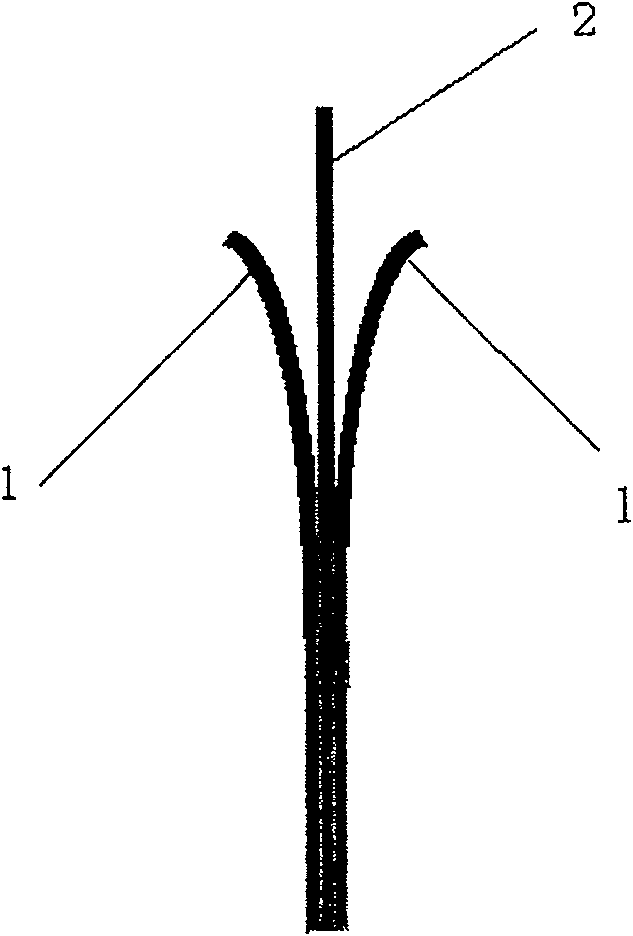

[0015] Cut the metal foil strip with a thickness of 0.05-0.2mm and a burr hole or square hole on the surface with a spacing of 0.5-2.0mm to the required size; mix activated carbon and PTFE emulsion in a ratio of 10:0.5-10:1, mix Use a stirring rod to stir in the same direction until the glue is connected, and then put it on the rolling machine to extend the horizontal and vertical alternate rolling until the carbon sheet has a certain elasticity and toughness, and the carbon sheet is made into a flexible activated carbon of 0.2-2.0mm sheet 1; the flexible activated carbon sheet 1 is attached to the burr metal belt current collector 2 with a press or a roller machine to make a supercapacitor electrode, as attached image 3 shown. The diameter of the burr round hole is 0.5~2.0mm, and the size of the square hole is (0.5×0.5mm)~(2.0×2.0mm). Metal foil strips refer to nickel metal foil strips, copper metal foil strips, and nickel-plated steel strips. The burrs on the metal foil ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com