Magnetic powder activation method for magnetic asphalt, magnetic asphalt preparation method, asphalt plate pouring method and waterproof bonding layer paving method

An activation method and technology of asphalt slabs, which are applied in construction, erection/assembly of bridges, bridges, etc., can solve problems such as poor retention, corrosion of steel bridge decks, and short effectiveness, and achieve simple construction techniques, simple transportation, and reduced agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

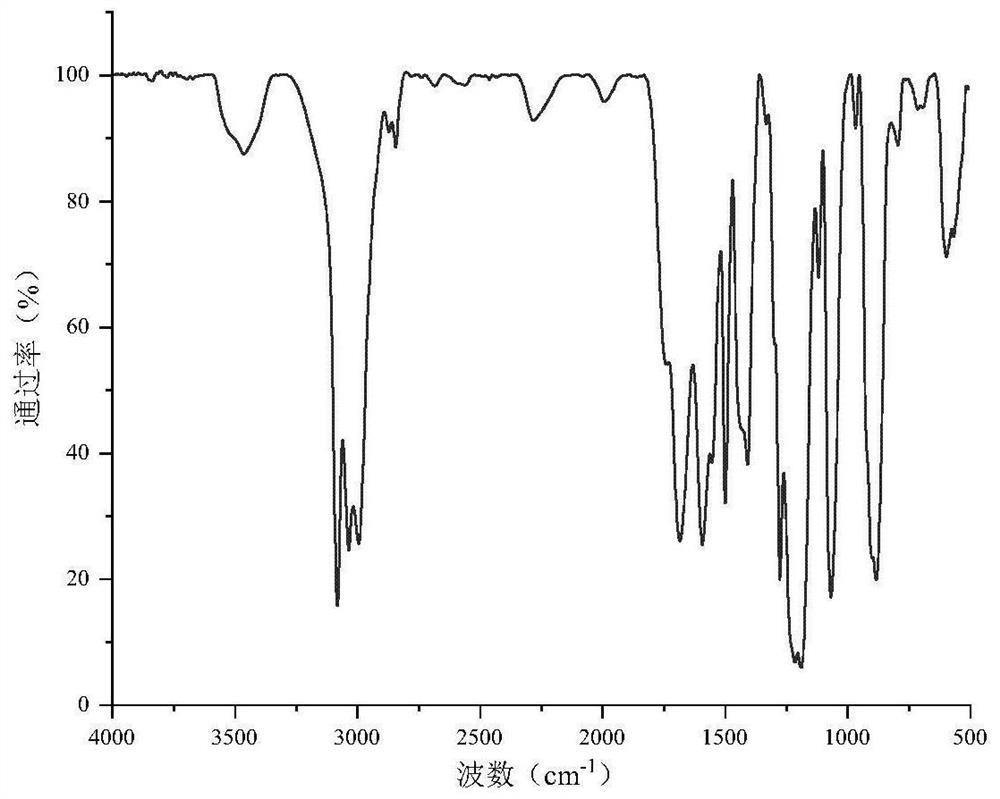

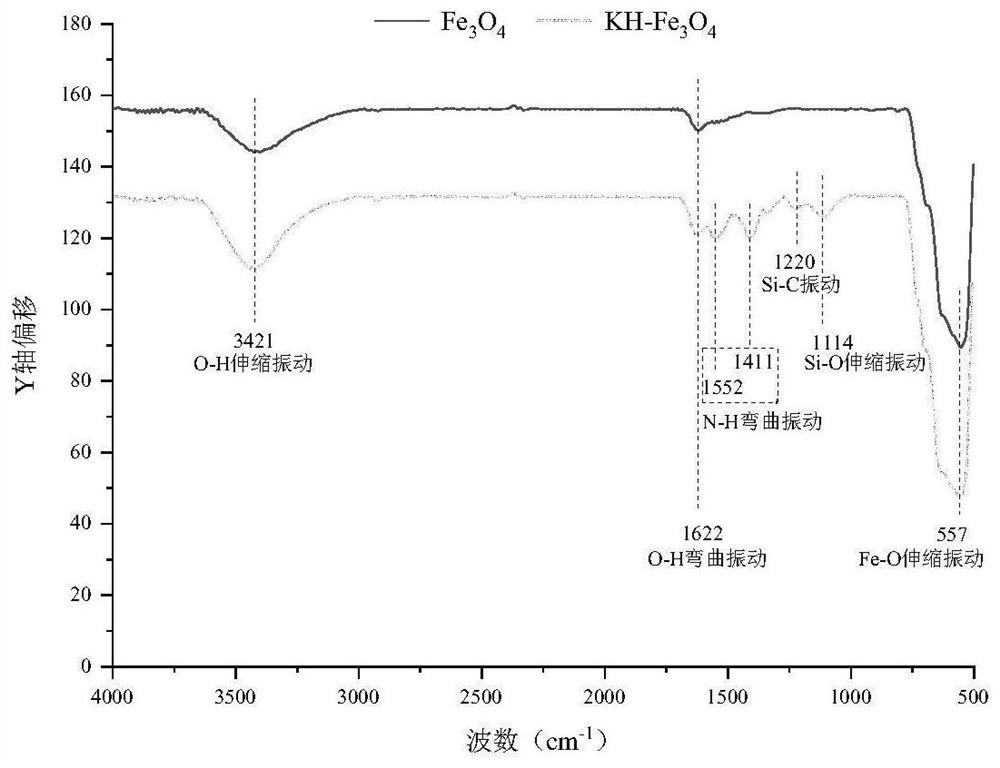

[0053] Prepare 30ml of deionized water and 70ml of absolute ethanol base solution, use acetic acid to adjust the pH value to 4.5, add 2ml of KH-550, ultrasonicate for 30min (water bath temperature 80°C, frequency 40KHz), weigh 10g of nano-Fe 3 o 4 (30nm) was added to the base solution, manually stirred for 5-10min, and then ultrasonically treated for 60min (water bath temperature 80°C, frequency 40KHz), using a magnet to 3 o 4 For adsorption, use deionized water to wash repeatedly, and finally dry and dry at 120°C to dry the obtained black solid particles. Infrared spectrogram see figure 2 .

Embodiment 2

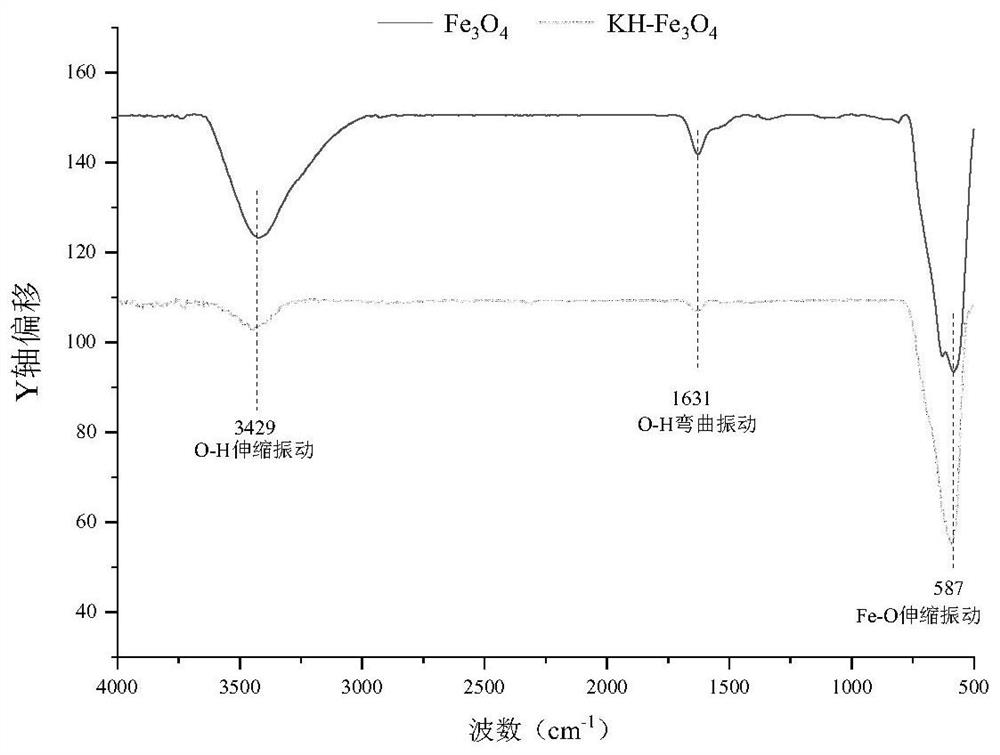

[0055] Prepare 30ml of deionized water and 70ml of absolute ethanol base solution, use acetic acid to adjust the pH value to 4.5, add 3ml of KH-550, ultrasonic treatment for 30min (water bath temperature 80°C, frequency 40KHz), weigh 10g NdFeB (100μm ) into the base solution, manually stirred for 5-10 minutes, then ultrasonically treated for 90 minutes (water bath temperature 80°C, frequency 40KHz), using magnets to adsorb NdFeB, repeated washing with deionized water, and finally drying and drying at 120°C , and dry the resulting black solid particles.

Embodiment 3

[0061] Weigh Donghai Brand No. 70 matrix asphalt produced by Sinopec, heat the asphalt to a molten state; add 200% of the mass of asphalt and the magnetic powder obtained by surface modification in Example 1, first stir at 1000r / min for 10min, control the temperature at 155°C, and then stir at 8000r / min 60min, the temperature is controlled at 165°C, and finally stirred at 1000r / min for 10min, the temperature is controlled at 155°C, and the magnetic pitch is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com