Pollution repairing method for water polluted by organic matters

A technology for pollution remediation and organic matter, applied in the field of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

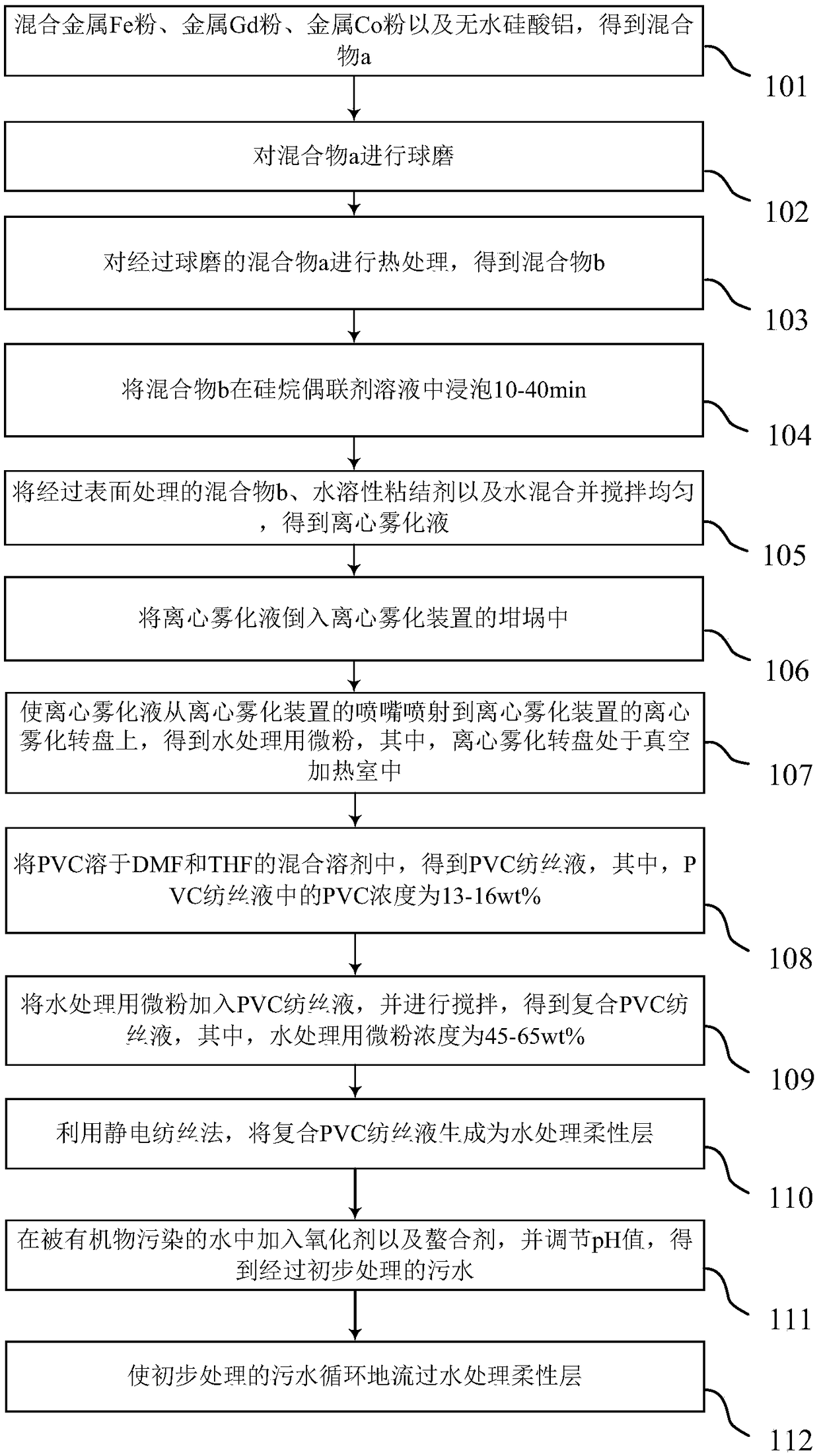

[0031]The pollution remediation method of the present invention comprises the following steps: mixing metal Fe powder, metal Gd powder, metal Co powder and anhydrous aluminum silicate to obtain a mixture a; ball milling the mixture a; heat-treating the ball milled mixture a to obtain a mixture b; soak the mixture b in the silane coupling agent solution for 10 minutes; mix the surface-treated mixture b, water-soluble binder and water and stir evenly to obtain a centrifugal atomized liquid; pour the centrifugal atomized liquid into the centrifugal fog In the crucible of the atomization device; spray the centrifugal atomization liquid from the nozzle of the centrifugal atomization device onto the centrifugal atomization turntable of the centrifugal atomization device to obtain micropowder for water treatment, wherein the centrifugal atomization turntable is in a vacuum heating chamber; PVC is dissolved in a mixed solvent of DMF and THF to obtain a PVC spinning solution, wherein th...

Embodiment 2

[0033] The pollution remediation method of the present invention comprises the following steps: mixing metal Fe powder, metal Gd powder, metal Co powder and anhydrous aluminum silicate to obtain a mixture a; ball milling the mixture a; heat-treating the ball milled mixture a to obtain a mixture b; soak the mixture b in the silane coupling agent solution for 40 minutes; mix and stir the surface-treated mixture b, water-soluble binder and water to obtain a centrifugal atomization liquid; pour the centrifugal atomization liquid into the centrifugal fog In the crucible of the atomization device; spray the centrifugal atomization liquid from the nozzle of the centrifugal atomization device onto the centrifugal atomization turntable of the centrifugal atomization device to obtain micropowder for water treatment, wherein the centrifugal atomization turntable is in a vacuum heating chamber; PVC is dissolved in a mixed solvent of DMF and THF to obtain a PVC spinning solution, wherein th...

Embodiment 3

[0035] The pollution remediation method of the present invention comprises the following steps: mixing metal Fe powder, metal Gd powder, metal Co powder and anhydrous aluminum silicate to obtain a mixture a; ball milling the mixture a; heat-treating the ball milled mixture a to obtain a mixture b; soak the mixture b in the silane coupling agent solution for 15 minutes; mix the surface-treated mixture b, water-soluble binder and water and stir evenly to obtain a centrifugal atomization liquid; pour the centrifugal atomization liquid into the centrifugal fog In the crucible of the atomization device; spray the centrifugal atomization liquid from the nozzle of the centrifugal atomization device onto the centrifugal atomization turntable of the centrifugal atomization device to obtain micropowder for water treatment, wherein the centrifugal atomization turntable is in a vacuum heating chamber; PVC is dissolved in a mixed solvent of DMF and THF to obtain a PVC spinning solution, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com