Etching device for fine circuit

An etching device and fine circuit technology, which is applied in the field of circuit board manufacturing, can solve the problems of abnormal etching, contact, and affect the surface state of products, and achieve the effect of ensuring etching accuracy and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

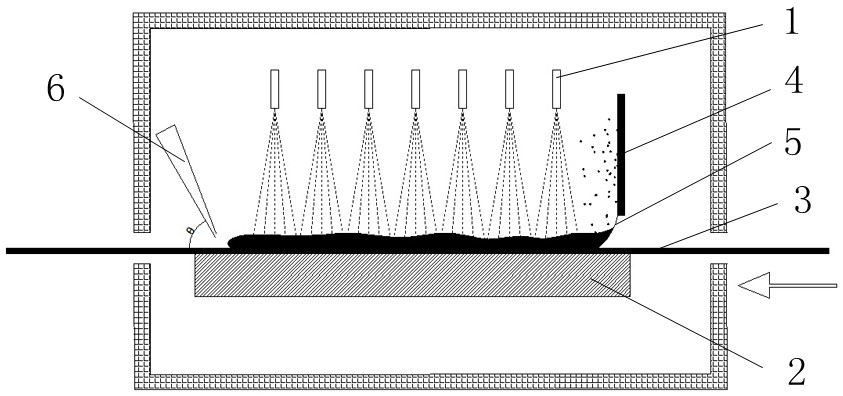

[0013] Such as figure 1 The etching apparatus of a fine line is characterized in that the etching pan 1 and the carrier plate 2 are etched, carrying the carrier 2 loaded by the product 3, the etching spray pan 1 is disposed above the product 3, etching the jet 1 consisting of a multi-etched nozzle, the nozzle of the etching pan 1 continues to etch on the product 3 of the etching liquid to the lower product 3 at a certain pressure, and a baffle 4 is provided above the traveling direction of the product 3, and the baffle 4 is set The front end of the etching disc 1, the bottom of the baffle 4 is provided with a blocking piece 5, and the baffle 4 prevents the spray liquid to sputter the pretreatment surface of the product 3, affect the line etching accuracy, and the blocking piece 5 prevents the chemical reflow. Go to the pre-processing surface of the product 3.

[0014] The windder 6 is provided above the rear end of the travel direction of the product 3, and the wind blade 6 is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com