Preparation method of electrolytic solution and black coating for micro-arc oxidation of magnesium alloy surface

A technology of electrolytic solution and micro-arc oxidation, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of strong adhesion of magnesium alloy substrate, low surface roughness of coating, high blackness of black coating, etc. , to achieve the effects of high hardness, elimination of local defects, and high impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

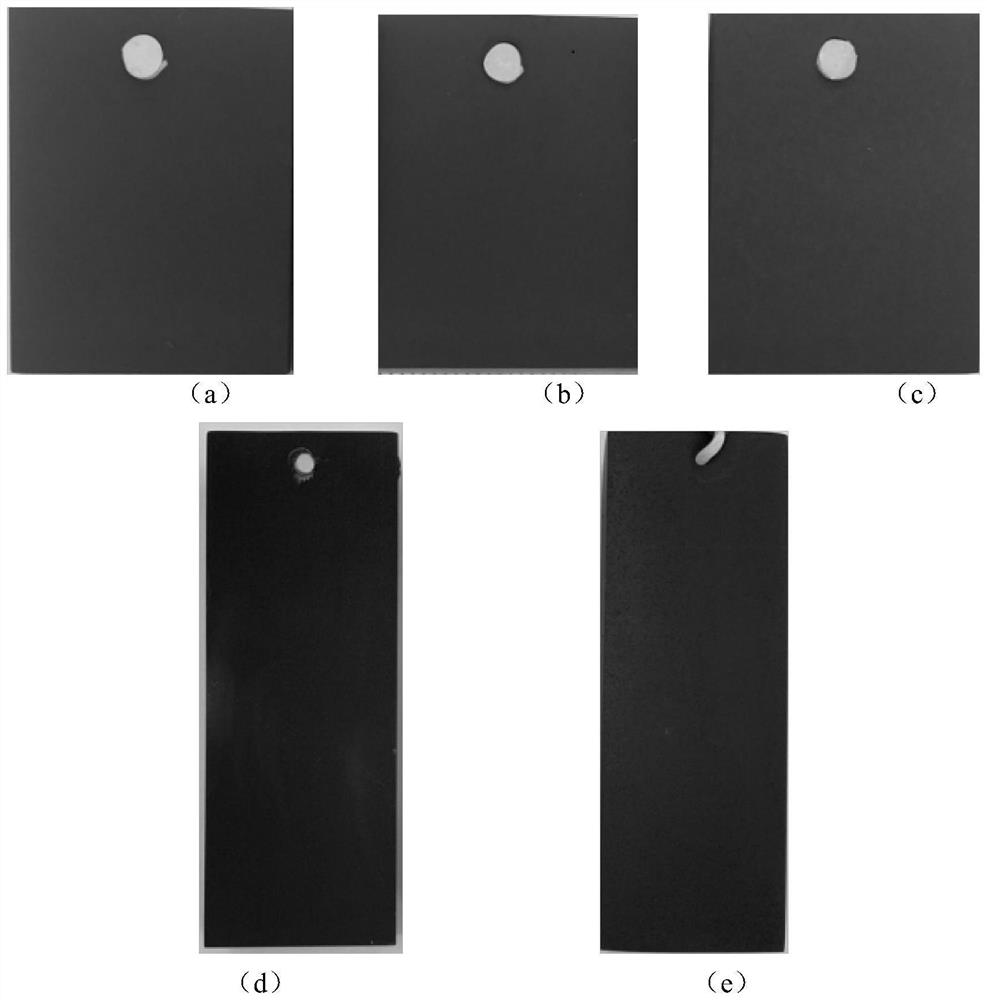

Embodiment 1

[0043] The content of each component in the electrolyte solution used is as follows: the main coloring salt is 10g / L copper sulfate, the complexing agent is 5g / L sodium ethylenediamine tetramethylene phosphonate (EDTMPS), 5g / L sodium tartrate and 5g / L Sodium pyrophosphate, the main film-forming agent is 25g / L sodium silicate, the auxiliary film-forming agent is 15g / L potassium hydroxide and 10g / L potassium fluoride.

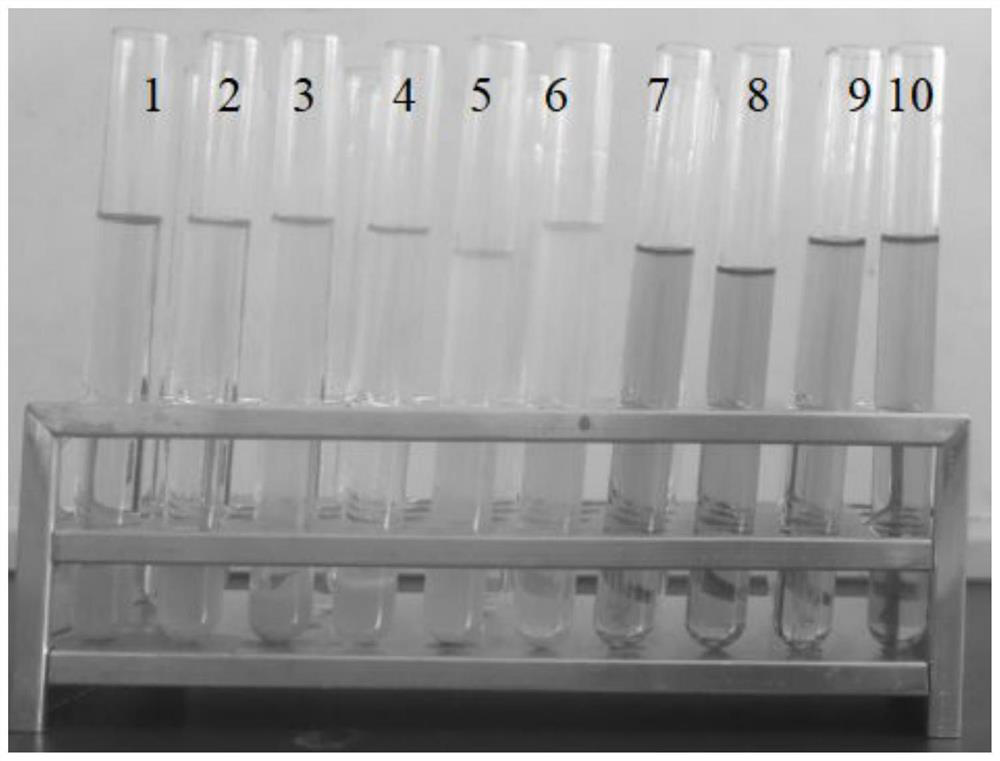

[0044] Preparation of electrolyte solution: Weigh 600ml of deionized water and pour it into a 2L beaker, first add 10g of copper sulfate, 5g of sodium ethylenediamine tetramethylene phosphonate (EDTMPS), 5g of sodium tartrate, and 5g of sodium pyrophosphate into the beaker, and use a magnetic Stir with a stirrer for 5 minutes; then add 25g of sodium silicate, 15g of potassium hydroxide, and 10g of potassium fluoride to the beaker in sequence, and stir for 5 minutes with a magnetic stirrer; make up the remaining amount of deionized water to 1L and stir again evenly...

Embodiment 2

[0050] The contents of each component in the electrolyte solution used are as follows: the main coloring salt is 10g / L copper pyrophosphate, the auxiliary coloring salt is 3g / L organic selenium, and the complexing agent is 3g / L sodium ethylenediamine tetramethylene phosphonate (EDTMPS ), 5g / L sodium tartrate and 3g / L sodium tripolyphosphate, the main film-forming agent is 25g / L sodium silicate, and the auxiliary film-forming agent is 15g / L potassium hydroxide, 10g / L potassium fluoride and 5g / L Sodium tetraborate, the stabilizer is 5g / L polyethylene glycol and 5g / L sodium lauryl sulfate, and the nano powder is 3g / L nano manganese dioxide and 3g / L nano graphene particles.

[0051] Preparation of electrolyte solution: Weigh 600ml of deionized water and pour it into a 2L beaker, first add 10g copper pyrophosphate, 3g organic selenium, 3g sodium ethylenediaminetetramethylene phosphonate (EDTMPS), 5g sodium tartrate, 3g sodium tripolyphosphate into the beaker, stirred with a magneti...

Embodiment 3

[0055] The contents of each component in the electrolyte solution used are as follows: the main coloring salt is 10g / L copper pyrophosphate, the auxiliary coloring salt is 5g / L cobalt acetate, and the complexing agent is 3g / L sodium polyphosphate, 6g / L sodium tartrate and 3g / L sodium ethylenediamine tetramethylene phosphonate (EDTMPS), the main film-forming agent is 25g / L sodium silicate, and the auxiliary film-forming agent is 5g / L potassium hydroxide, 10g / L potassium fluoride and 10g / L Sodium tetraborate, the stabilizer is 5g / L polyethylene glycol and 2g / L sodium lauryl sulfate, and the nano powder is 3g / L nano titanium dioxide and 3g / L nano cobalt oxide.

[0056] Preparation of electrolyte solution: Weigh 600ml of deionized water and pour it into a 2L beaker, first add 10g of copper pyrophosphate, 5g of cobalt acetate, 3g of sodium polyphosphate, 6g of sodium tartrate, and 3g of ethylenediamine tetramethylene phosphonate (EDTMPS) into the beaker, stirring continuously with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com