Method for enhancing fluorescence of MXene quantum dots

A technology of fluorescence enhancement and quantum dots, which is applied in chemical instruments and methods, nano optics, luminescent materials, etc., can solve the problems of practical application difficulties, poor fluorescence emission performance, and low fluorescence quantum yield, so as to improve the fluorescence emission ability, The effect of low cost and simple enhancement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

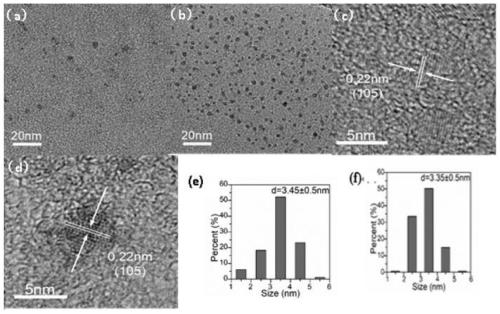

[0031] Preparation of Ti by hydrothermal method 3 C 2 QDs as an example. Use a reactor to prepare Ti by heating and reacting in the reactor 3 C 2 QDs. Specifically: the Ti 3 AlC 2 The powder is added to a certain concentration of HF aqueous solution, and the HF aqueous solution will etch away the Al element in it to obtain the MXene material. The obtained MXene material was dissolved by adding deionized water, and ultrasonically treated until the solution was uniform and transparent without precipitation. And the clear solution was reacted in an autoclave at 120°C for 6h. Finally, the solution obtained by the reaction is filtered with a filter membrane to obtain Ti 3 C 2 Aqueous solution of MQDs (0.1 mg / mL).

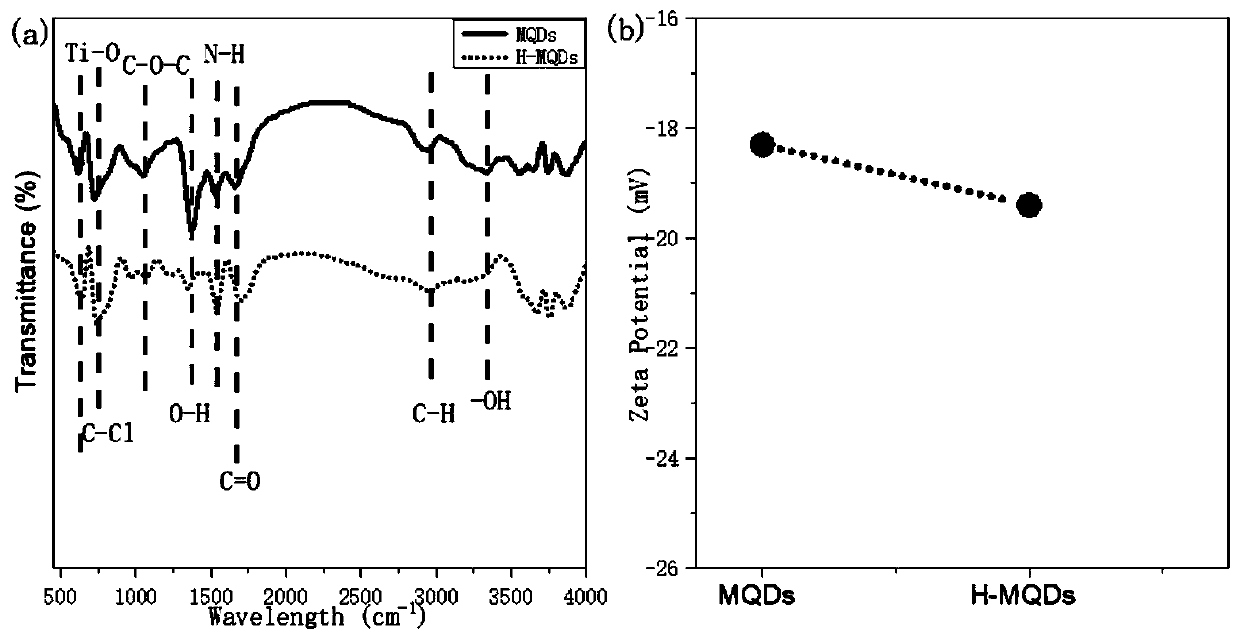

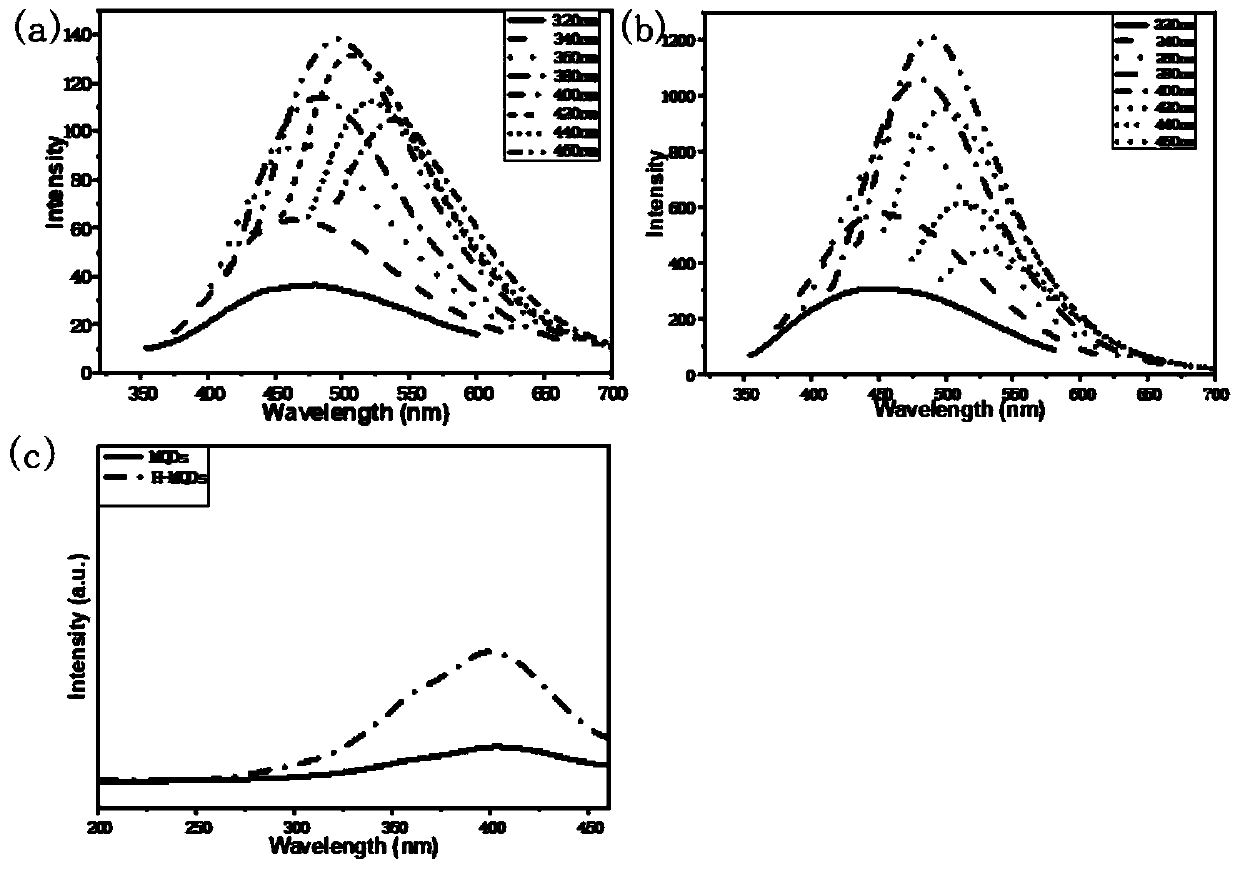

[0032] Subsequent to the obtained Ti 3 C 2 QDs are subjected to hydrogen peroxide (H 2 o 2 ) post-treatment carries out surface modification to quantum dots, modification method is: step 1. the volume fraction is the 30% H of 10 μ L 2 o 2 Add to 2mL MQ...

Embodiment 2

[0040] Preparation of Ti by alkali reflux method 3 C 2 QDs as an example. Preparation of Ti by NaOH-Assisted Reflux Method 3 C 2 QDs. Specifically: the Ti 3 AlC 2 The powder is added to a certain concentration of HF aqueous solution, and the HF aqueous solution will etch away the Al element in it to obtain the MXene material. The obtained MXene material was added into a mixed solution of sodium hydroxide, polyethylene glycol 200 (PEG 200) and deionized water for dissolution, and ultrasonic treatment was performed to make the solution uniform and transparent without precipitation. And the resulting clear solution was refluxed at 120 °C for 6 h. In order to remove impurities, the resulting clear solution is finally dialyzed with a semi-permeable membrane to obtain Ti 3 C 2 Aqueous solution of MQDs (0.1 mg / mL).

[0041] Subsequent to the obtained Ti 3 C2 Hydrogen peroxide (H 2 O 2 ) post-treatment to modify the surface of the quantum dots and to detect the fluores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com