30Mn*280 orbit square steel cold drawing deformation aging heat processing technique for large-scale port machine

A technology of aging heat treatment and normalizing heat treatment, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as size deviation, achieve good surface quality, improve hardness and wear resistance, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

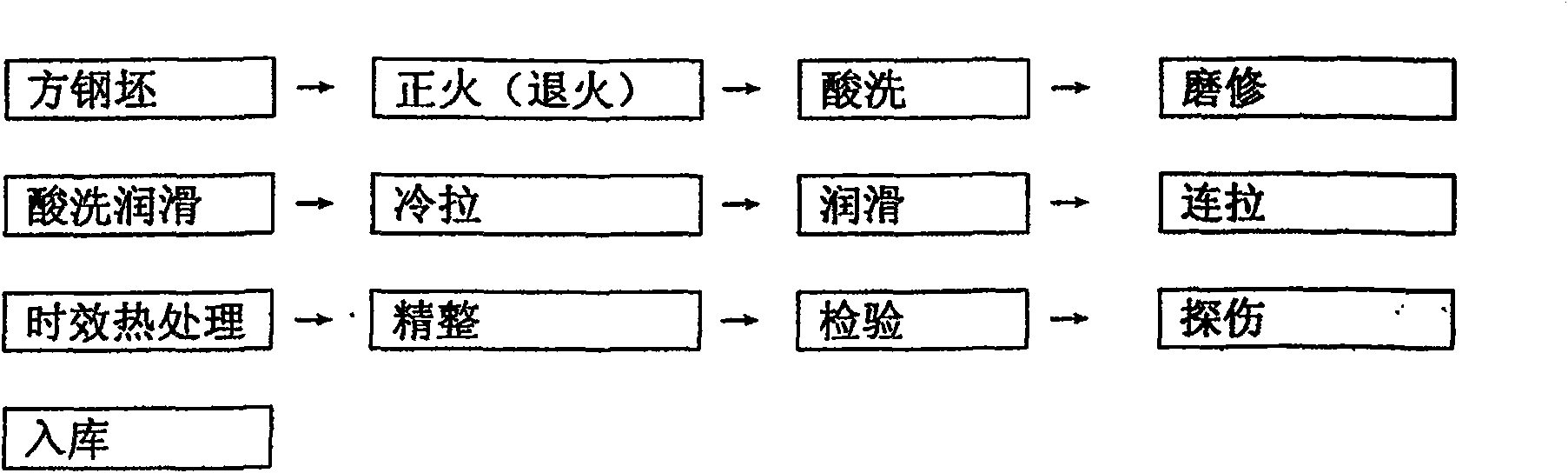

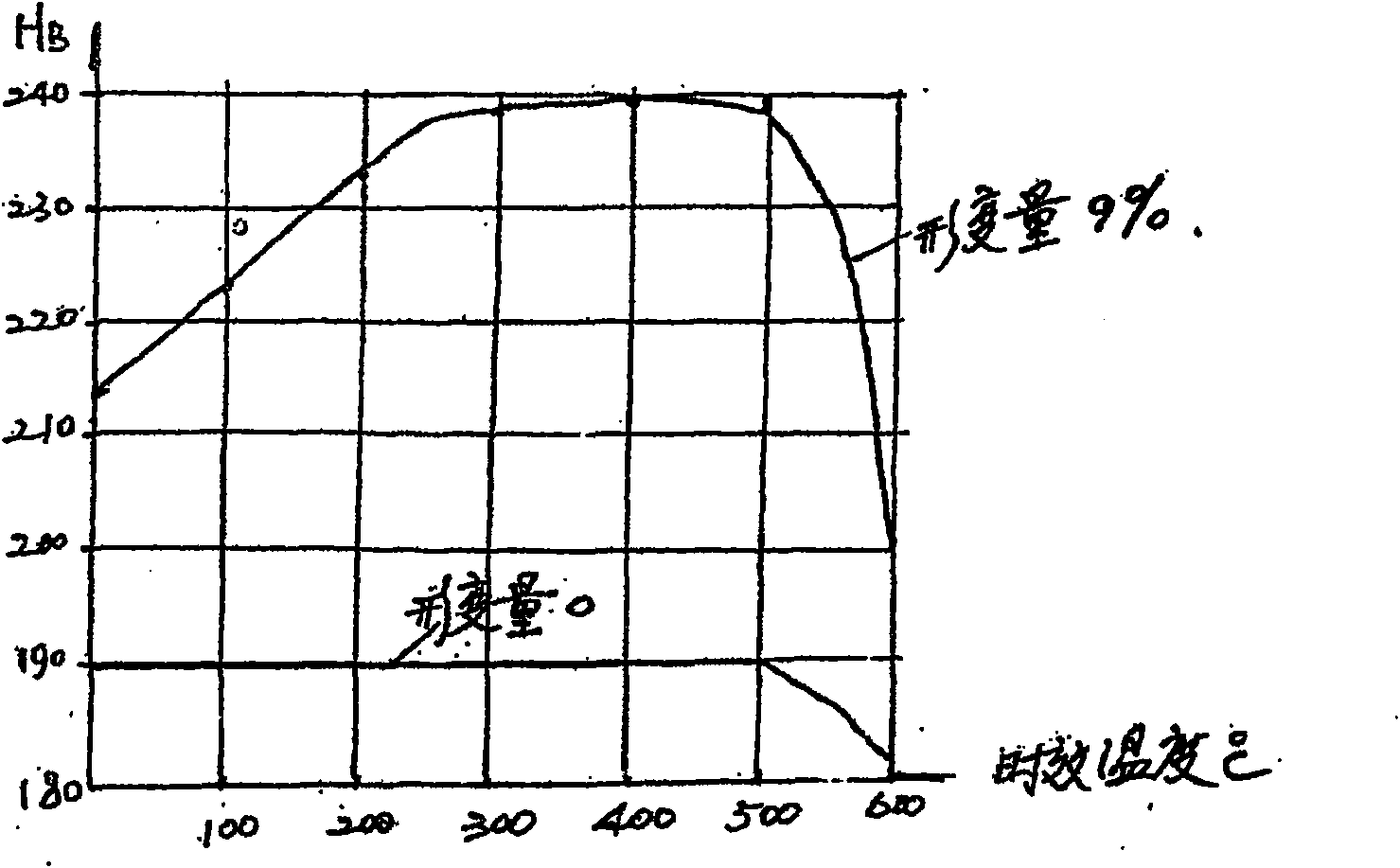

[0027] see figure 1 , the invention is a 30Mn 2 80 track square steel cold-drawing deformation aging heat treatment process, firstly, the hot-rolled square steel billet is normalized in a continuous furnace, the normalizing heat treatment temperature is 860-880 ° C, the holding time is 40 minutes ± 5 minutes, air-cooled to room temperature, and then, the second One cold drawing, the elongation coefficient μ is controlled at 1.04-1.05, and then the aging heat treatment is carried out when the second continuous drawing reaches the finished product size of 80*80, the total elongation coefficient μ is controlled at 1.09-1.1, the aging heat treatment temperature is 400-450°C, and heat preservation Time 90 minutes ± 10 minutes, air cooling. The specific discussion is as follows.

[0028] 1. Grinding of hot-rolled square billets

[0029] Grinding is one of the key processes to ensure the surface quality of track square steel. Defects such as cracks, warped skins, and pits on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com