Non-halogen phosphoric acid ester combustion inhibitor for engineering plastic and method of preparing the same

A technology of halogen-free phosphate ester and engineering plastics, which is applied in the direction of fire-resistant coatings, etc., can solve problems such as application restrictions, and achieve the effects of reduced production costs, high strength, and good processing performance

Active Publication Date: 2010-09-08

ZHEJIANG WANSHENG

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the early 1990s, based on the requirements of environmental protection and sustainable development, the call for non-halogenated flame-retardant engineering plastics has become more and more popular. Some brominated flame retardants have been banned, and some are also treated with prudence. App is restricted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

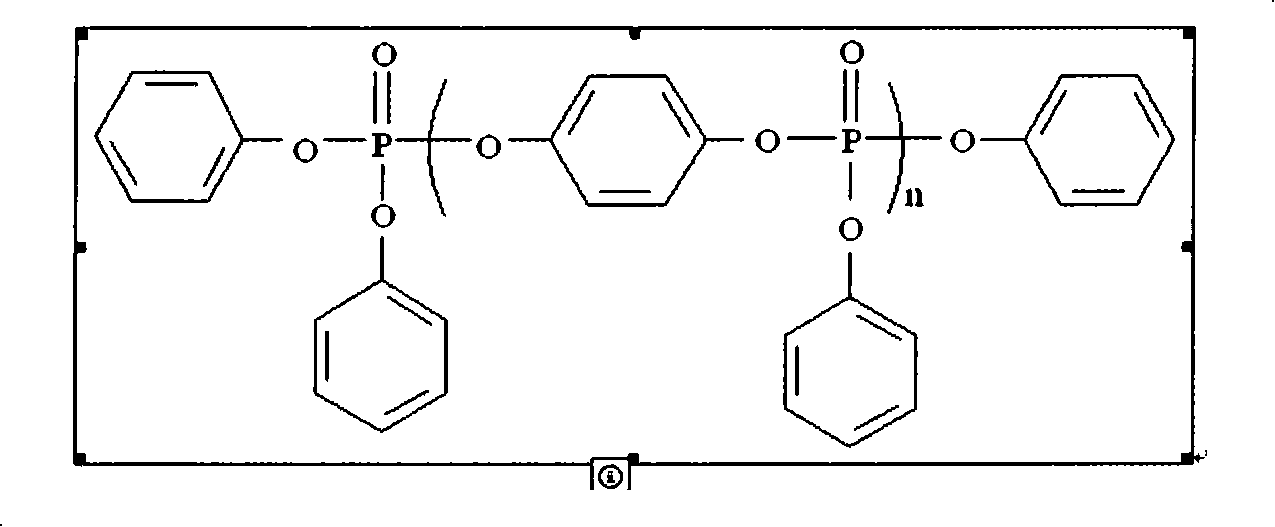

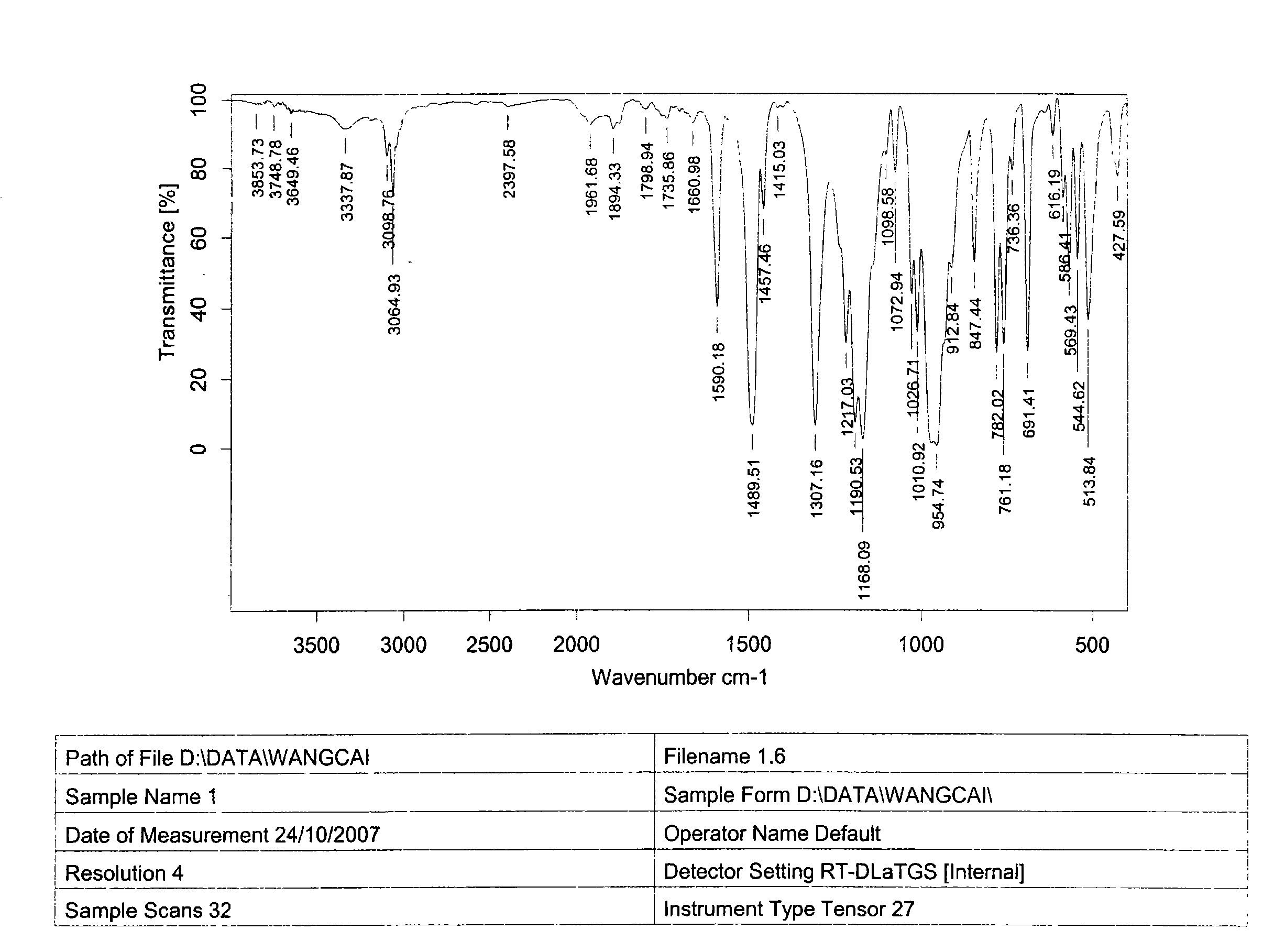

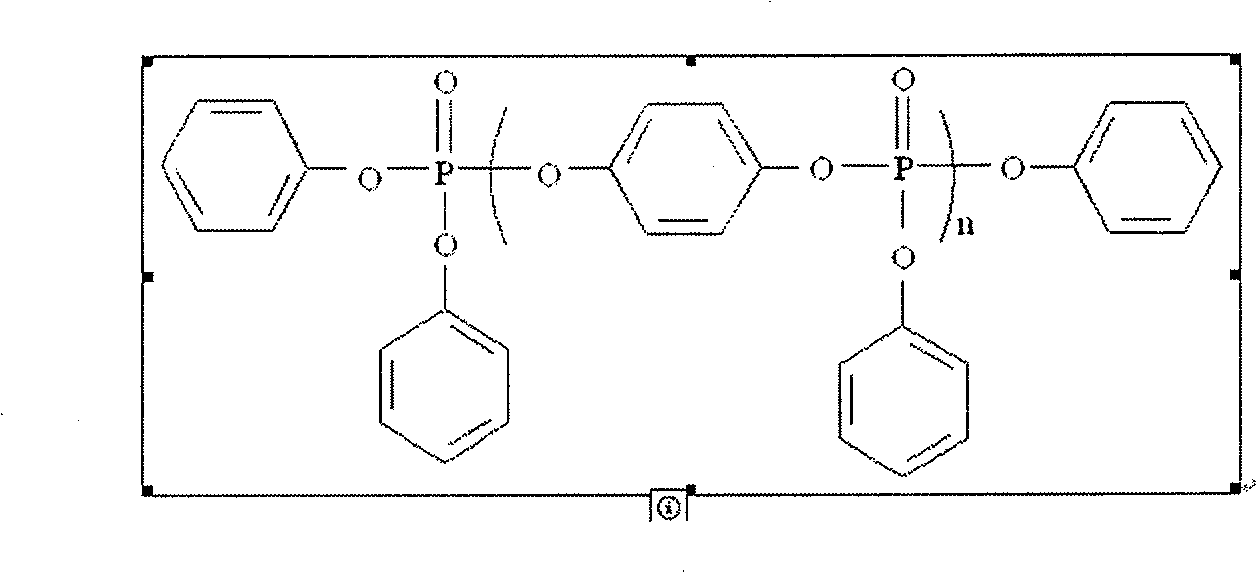

The invention relates to a halogen-free phosphate fire retardant used for engineering plastics and a method for producing the same, belonging to the engineering plastic fire retardant and the method for synthesizing the engineering plastic fire retardant technical field. The chemical name of the fire retardant is hydroquinone double phenyl bisphosphate oligomer, and the chemical structural formula is shown on the bottom right. The method comprises the following processing steps: firstly, the method adopts hydroquinone and phosphorus oxychloride as raw materials and a lewis acid as a catalyst for heating reaction; and secondly, the reaction mixture is heated up and dripped with phenol for reaction by taking the lewis acid as the catalyst. The production method has sufficient supply of the raw materials and simple reaction conditions, can reduce the manufacturing cost, and makes products have obvious price advantage; and simultaneously the material has the characteristics of zero halogen, low smoke, low toxity, low corrosiveness, high heat distortion temperature, good fire resistance, good processability, capability of being recycled, etc., and can be widely used as the fire retardant of various engineering plastics.

Description

technical field The invention belongs to the technical field of engineering plastic flame retardants and their synthesis methods, in particular to a halogen-free flame retardant hydroquinone bisphosphate phenyl ester oligomerization for PC, PA, PBT, PPO and alloy engineering plastics substances and their synthesis methods. Background technique Scientific experiments and years of practical experience have proved that the use of flame-retardant plastics and other flame-retardant materials is one of the most important strategic measures to improve the fire safety of products, protect people's lives and property, and protect the environment. It has attracted great attention and attention in various sectors of the national economy. Attention, and has become the manufacturer's due commitment to consumers. Since the beginning of the new century, various application fields of engineering plastics have put forward more and more stringent requirements for their flame retardancy, espe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08K5/523C09K21/12

Inventor 金译平吕云兴王轶

Owner ZHEJIANG WANSHENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com