Novel intelligent piezo-electricity type electrohydraulic servo valve

An electro-hydraulic servo valve, intelligent technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of large volume, inability to meet the requirements of sensitivity and precision, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

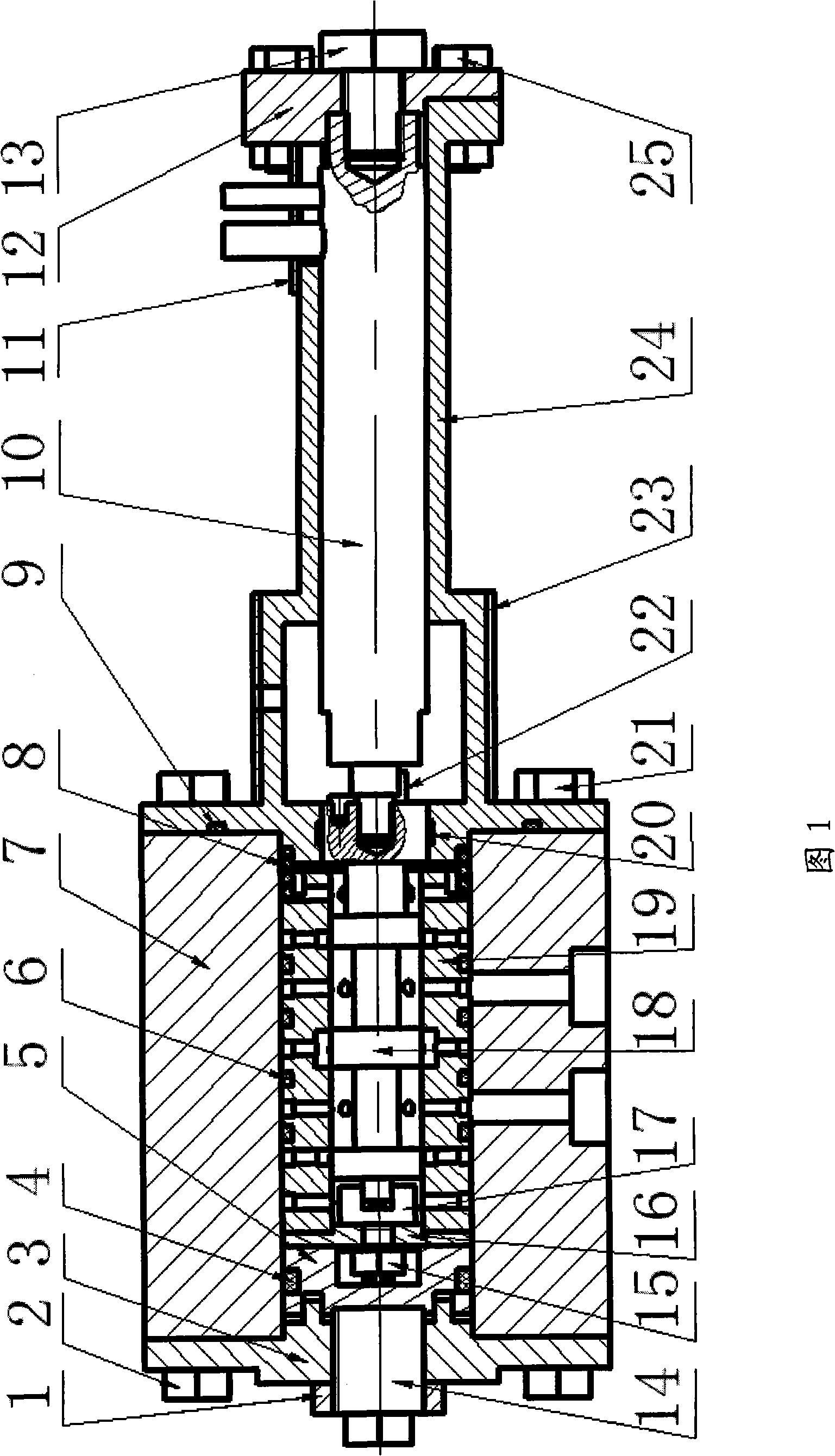

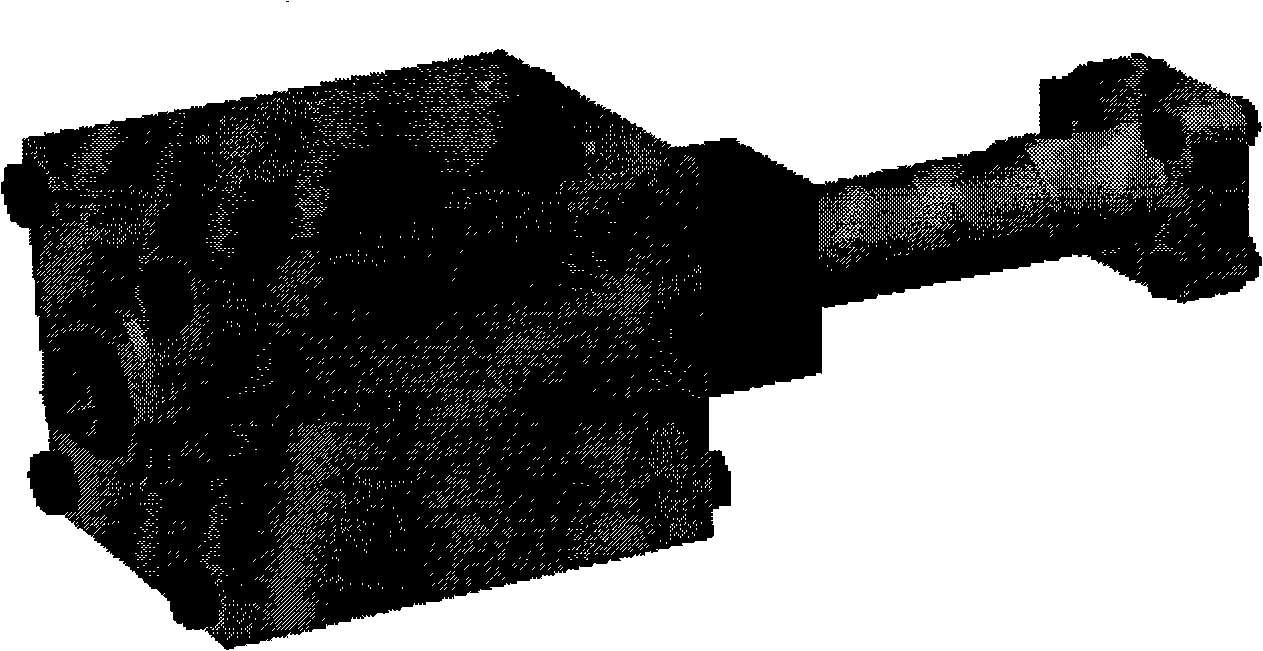

[0016] The present invention will be described in further detail below, see FIG. 1.

[0017] The novel intelligent piezoelectric electro-hydraulic servo valve of the present invention includes a shell composed of a left end cover 3, a valve body 7, a right end cover 23, a closed-loop piezoelectric ceramic driver seat 12 and a right end cover plate 22. The valve body 7 has a through valve cavity, a slide valve sleeve 18 is arranged in the valve cavity, and a valve core 17 is arranged in the through hole of the valve sleeve 18. The left end cover 3, the zero adjusting bolt 14, the sealing ring 4 and the valve sleeve adjusting medium pressure column 5 together cover the left end surface of the valve cavity. The right end cover 23 covers the right end surface of the valve cavity, and there are sealing rings 9 and 19 between the right end cover 23 and the right end surface of the valve cavity. The closed-loop piezoelectric ceramic driver seat 12 is fixed on the right end of the right e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com