Preparation method of paraffin organization chip

A technology of tissue chip and paraffin, which is applied in the field of paraffin tissue chip preparation, can solve the problems of unsatisfactory production effect, expensive equipment, complicated method, etc., and achieve the effect of easy learning and mastering, simple method and good experimental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A method for preparing a paraffin tissue chip, comprising the following steps:

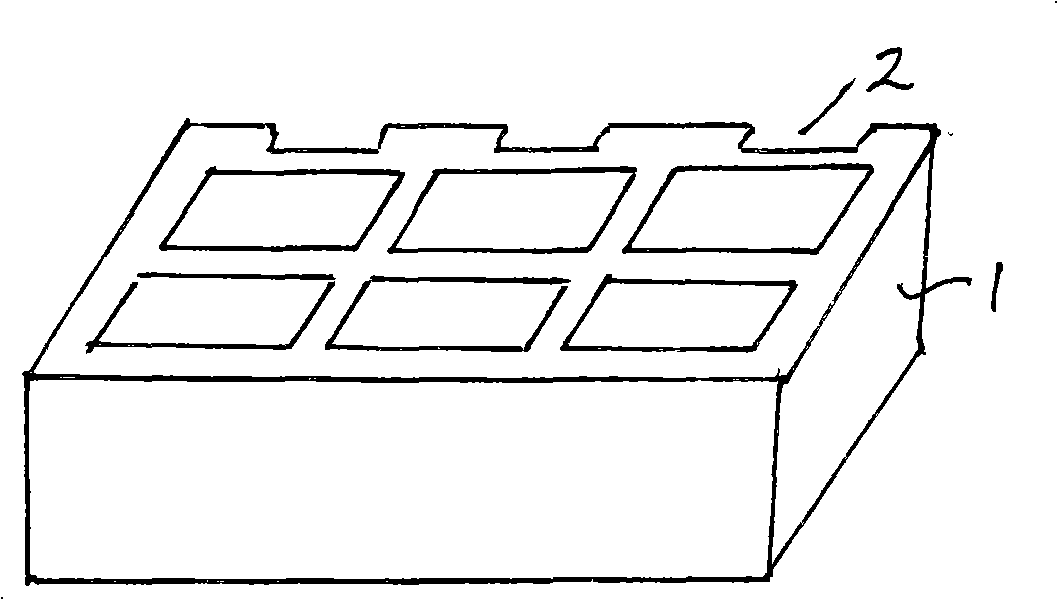

[0039] (1) Customized paraffin mold: the appearance is a rectangular porous cube. The paraffin mold is made in the form of horizontal multi-row holes and vertical two-row holes. The outer wall of the paraffin mold is provided with a concave anastomosis that matches the tissue array orifice plate; it can be used to customize tissue chip paraffin or make ordinary paraffin embedded blocks. Its thickness has various patterns.

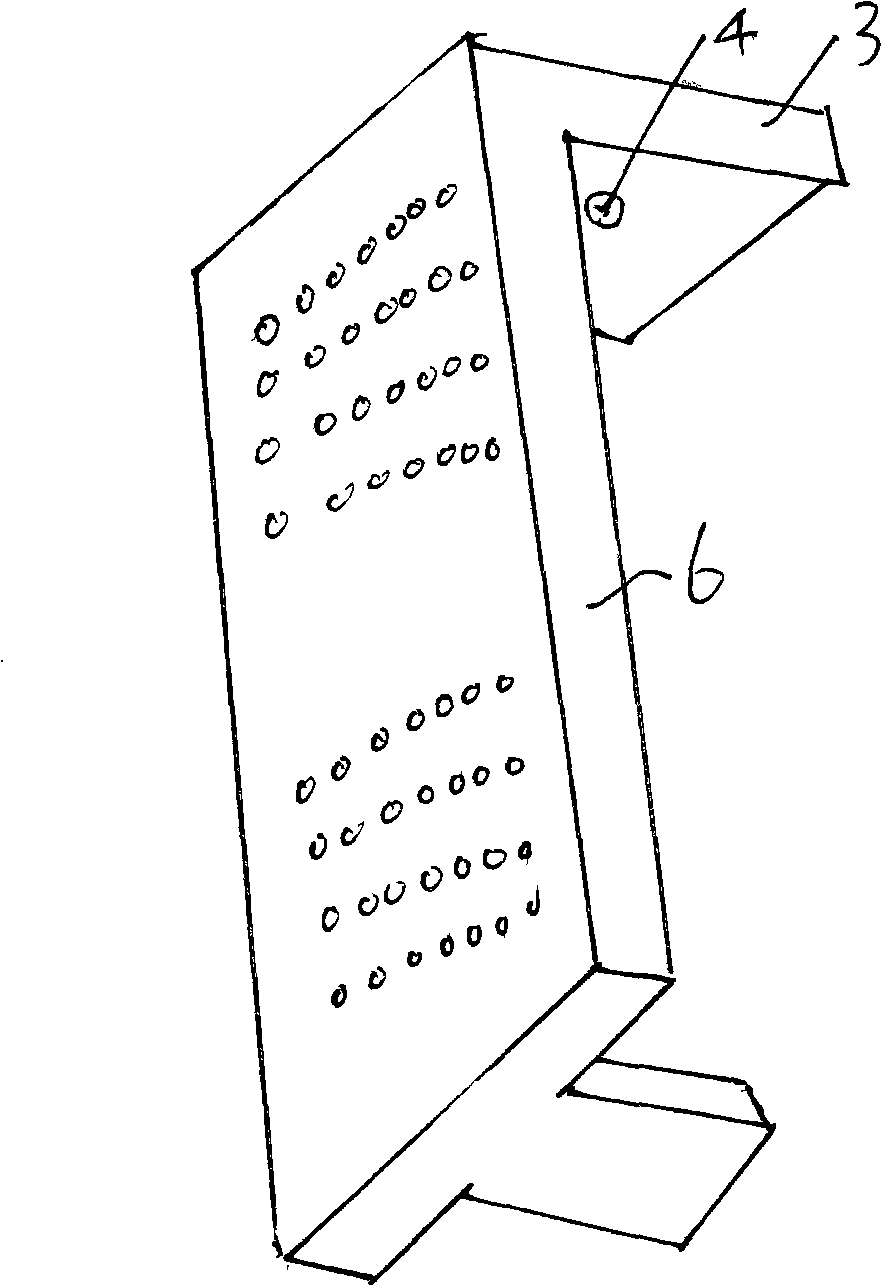

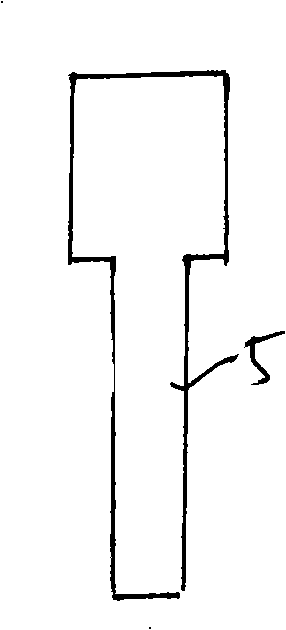

[0040] (2) Customized tissue array orifice plate: the overall longitudinal outer surface of the array orifice plate is slightly U-shaped, and one end of the plate body is beak-like convex and the paraffin mold concave is matched with each other; the other end is provided with the array orifice plate and the paraffin mold. Fixed fixing screws; the array orifice plate is longitudinally provided with two sets of arrays separated up and down, each set of arrays is only arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com