Humeral component of a shoulder joint prosthesis

A shoulder joint and component technology, which is applied in the field of humerus components, can solve the problem of unsuitable reversible shoulder prosthesis and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

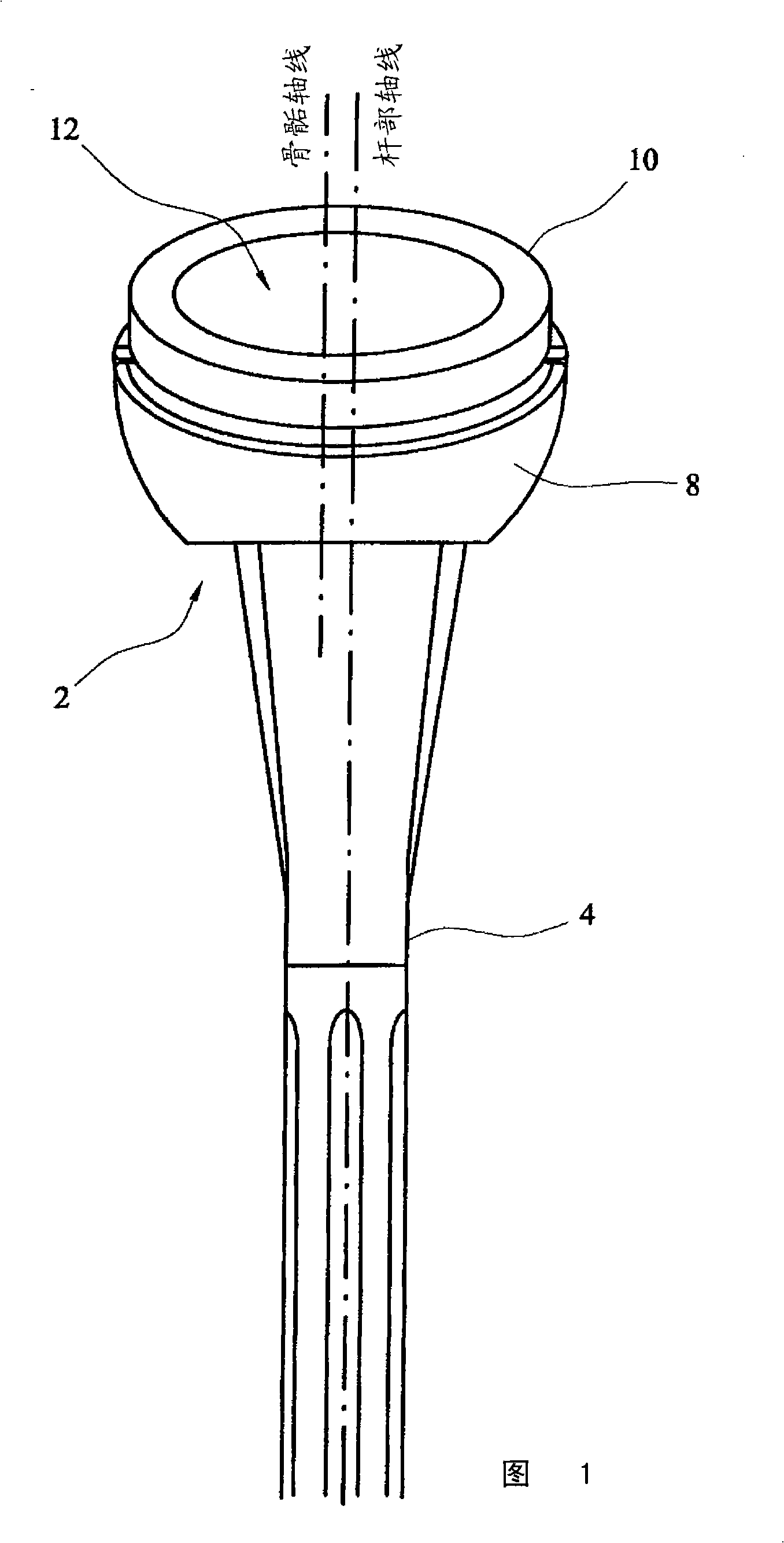

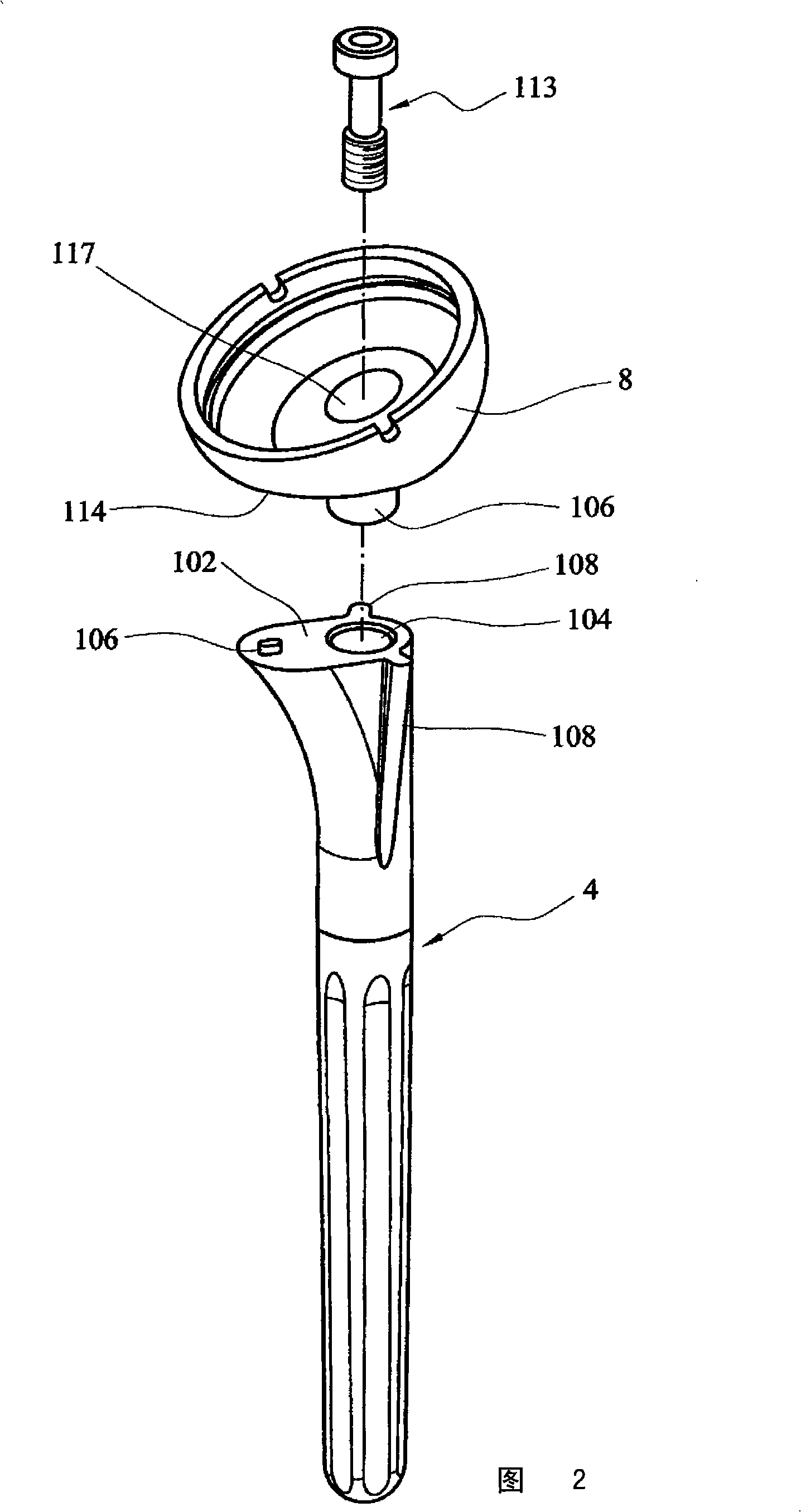

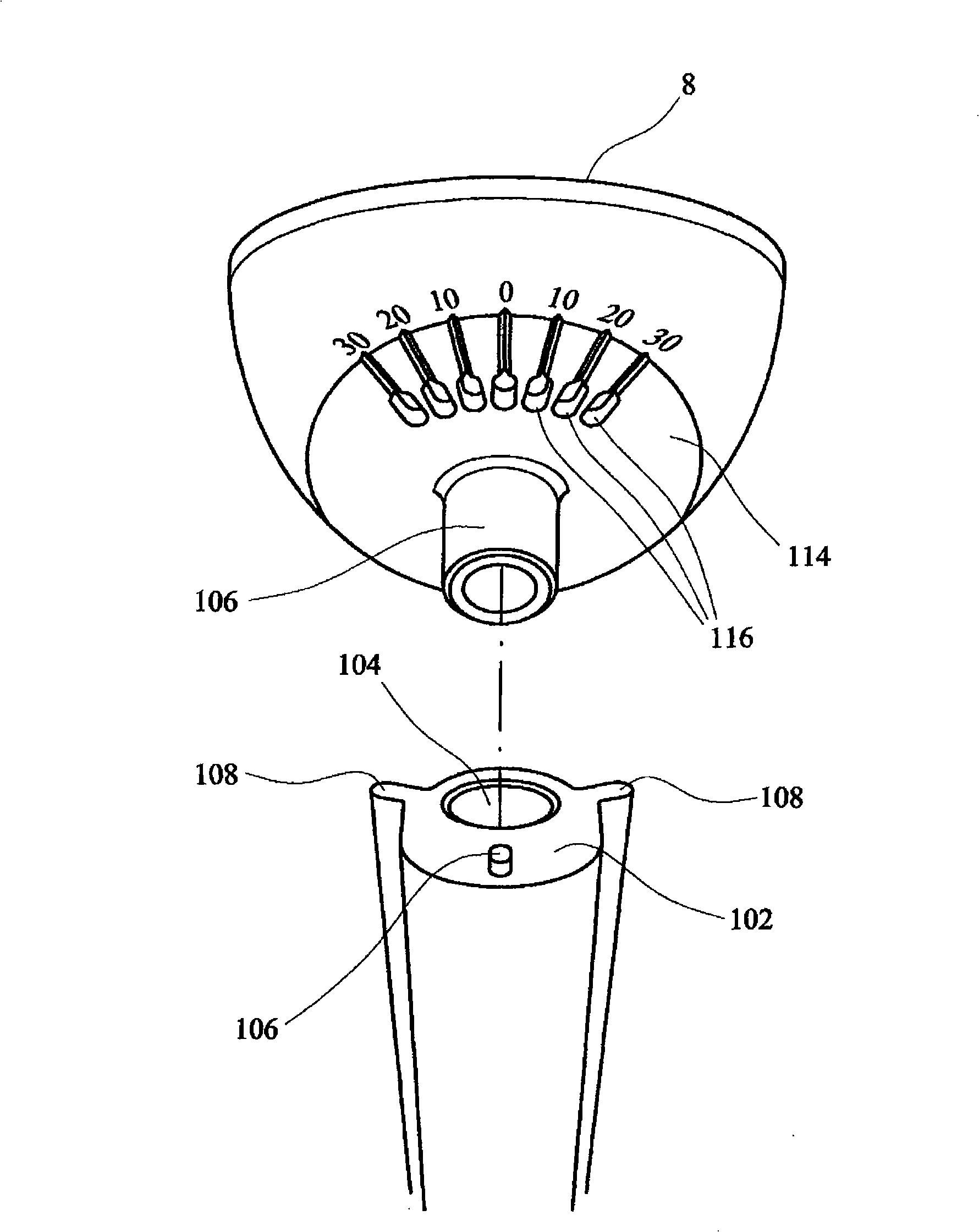

[0033]See attached drawings, Figures 1 through Image 6 The humeral component 2 in a reverse shoulder prosthesis is shown. The humeral component includes an elongated shaft section 4 for placement within the intramedullary cavity of a humerus 6 . The epiphyseal section 8 defines a recess for the bearing section 10 . The bearing section has a concave bearing surface 12 for articulation with a convex bearing surface of a glenoid component (not shown).

[0034] The shaft section 4, the epiphyseal section 8 and the load bearing section 10 are provided as separate modular sections which are assembled together prior to implantation to form the humeral component. Features included in modular orthopedic joint prostheses, especially shoulder prostheses, are already available, for example, from the DELTA and GLOBAL prostheses manufactured and sold by DePuy Products Inc and from the AEQUALIS prosthesis manufactured and sold by Tornier S.A. It is known that said features are suitable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com