Transparent polymer nanocomposites containing nanoparticles and method of making same

A nano-composite material and nano-particle technology, applied in the field of transparent polymer nano-composite materials, can solve the problems of non-quality and quantitative acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Preparation of ZnO / PMMA Nanocomposite

[0070] Granule preparation

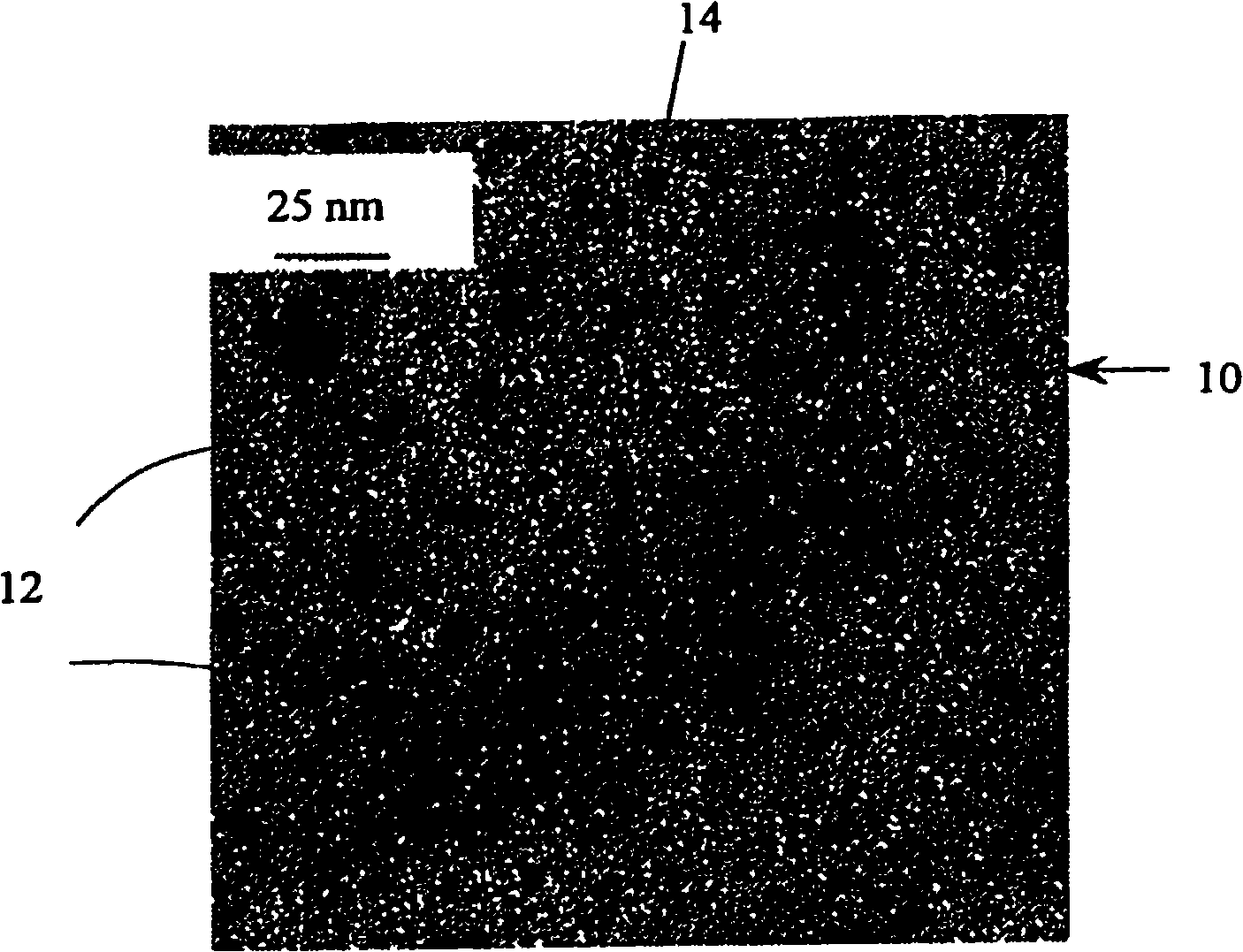

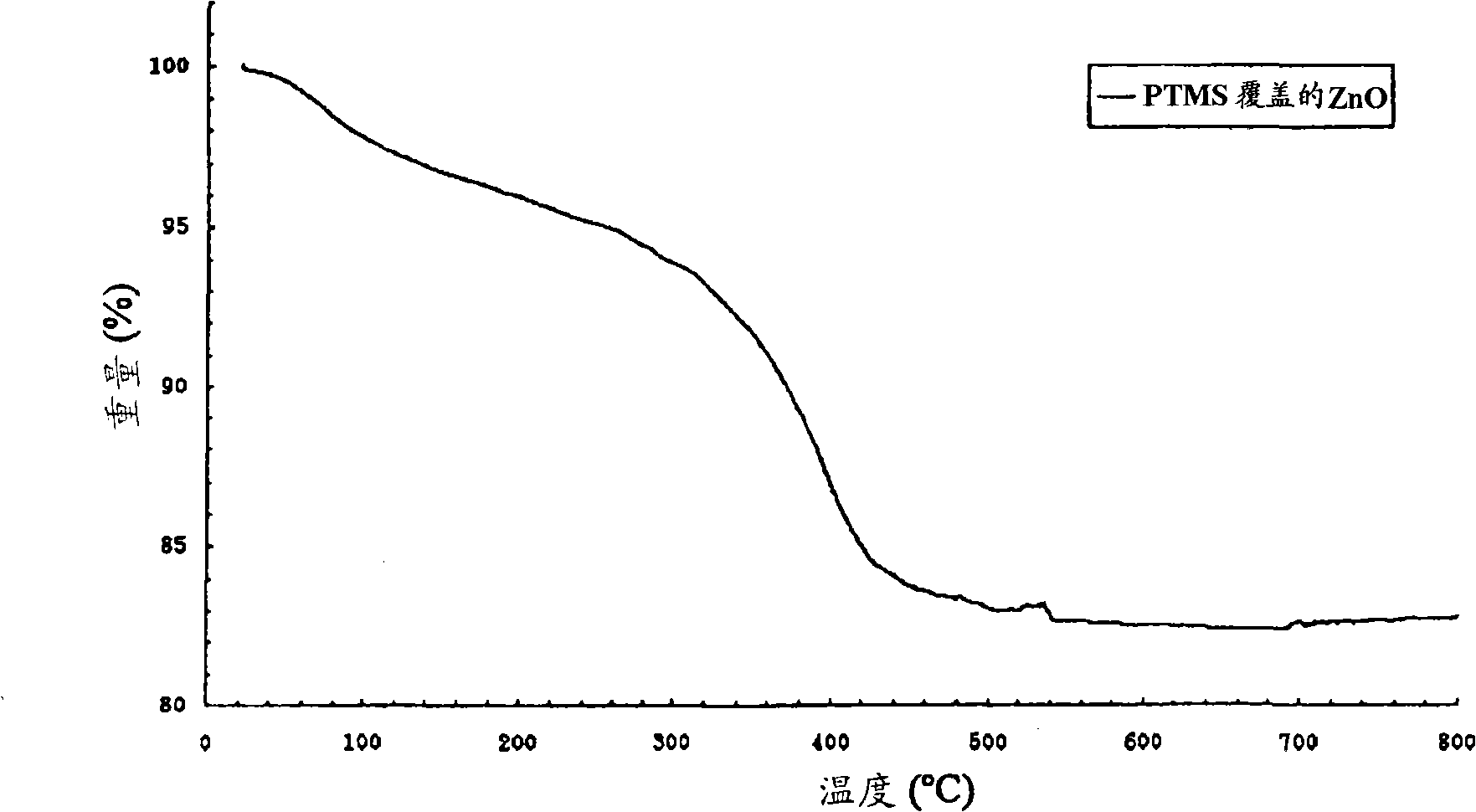

[0071] Solvents and reagents used in this and subsequent examples were reagent grade and were used without further purification. Alcoholic solutions of ZnO nanoparticles prepared by many methods available in the literature can be used for the preparation of nanoparticles with diameters less than 10 nm. In this example, a modification of the method of Bahnemann et al. (J. Phys. Chem., 91:3789, (1987)) will be used. Briefly, 0.439 g (2 mmol) of zinc acetate dihydrate (98%) was dissolved in 160 mL of 2-propanol with stirring at 50° C., after which the solution was further diluted to 1840 mL. 0.16 g (4 mmol) of sodium hydroxide pellets (99.99%) were dissolved in 160 mL of 2-propanol at 50°C and this solution was added to the zinc acetate solution at 0°C with stirring. The mixture was placed in a water bath preheated to 60°C for 2 hours. The reaction solution was then concentrated to 50 ml by a rotary eva...

Embodiment 2

[0077] Preparation of ZnO / PSt Nanocomposite

[0078] Granule preparation

[0079] The same method as described in Example 1 was followed.

[0080] Preparation of covering solution and covering ZnO

[0081] The same procedure as described in Example 1 was followed except that p-(trimethylsilyl)phenylmethylmercaptan (TMSPMT) from Wako Chemicals was used instead of BM.

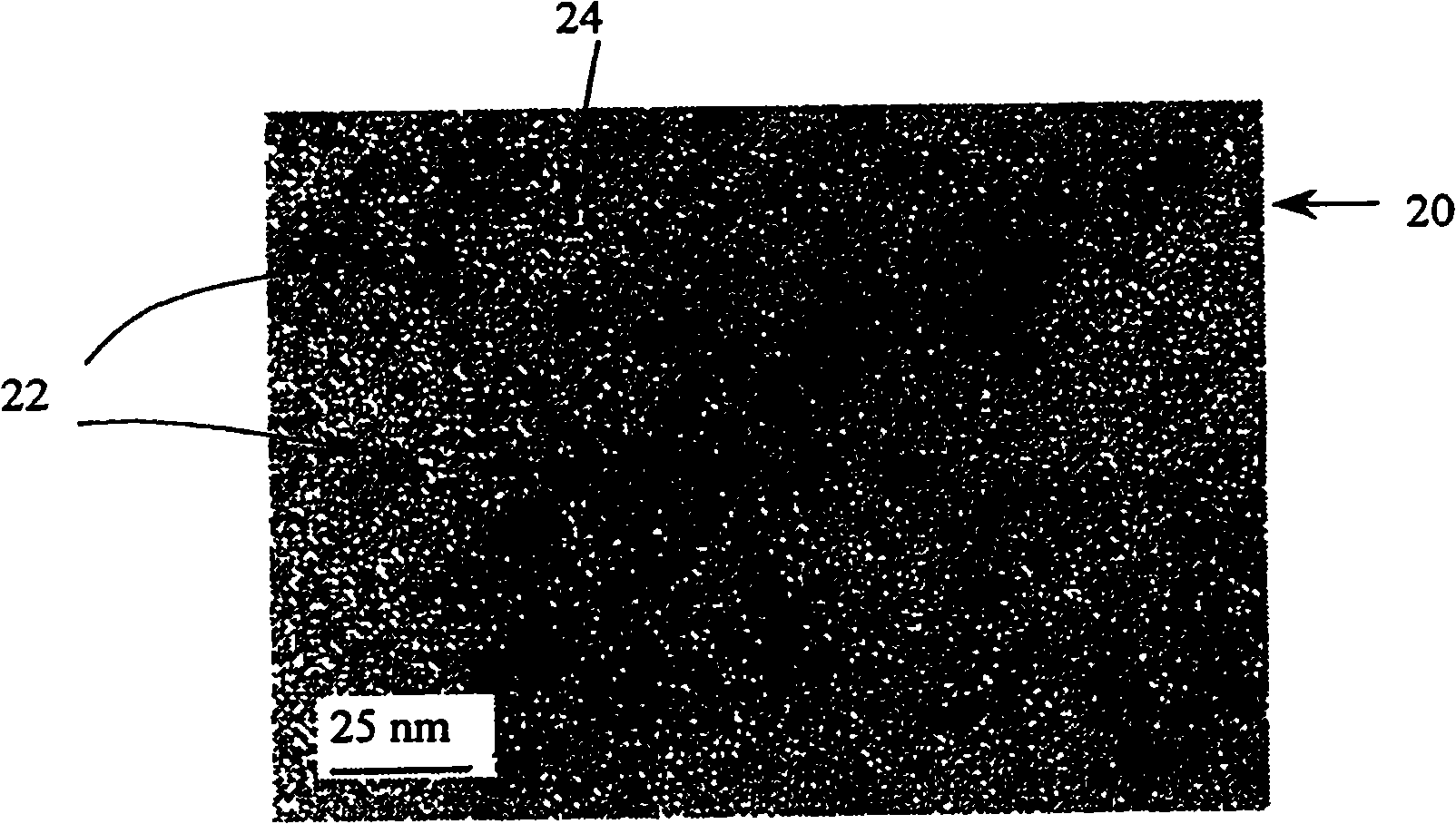

[0082] A solution of 0.393 g (2 mmol) TMSPMT in methanol (10 ml) was prepared. The TMSPMT solution was quickly added to the reaction solution with stirring. The ZnO nanocrystals are covered by TMSPMT and flocculation of the nanocrystals leads to the formation of a yellowish or white precipitate. The precipitate was allowed to settle and then separated from the liquid phase by centrifugation. The collected precipitate was redispersed in methanol to form a cloudy suspension and centrifuged. This purification process was repeated once. The purified precipitate was dried in a vacuum oven at room temperature fo...

Embodiment 3

[0086] Preparation of ZnO / PMMA Nanocomposite

[0087] Granule preparation

[0088] In this example, a modification of the method disclosed by Li et al. in US Patent Publication No. US20050260122 will be used. Briefly, 8.78 g (0.04 mole) of zinc acetate dihydrate (98%) was dissolved in 200 mL of methanol with stirring at 60°C, after which the solution was cooled to 25°C. The base solution was prepared using 4.489 g (0.08 mol) of potassium hydroxide pellets (85%) which were dissolved in 800 mL of methanol with stirring and maintaining the temperature at 60°C. The zinc acetate dihydrate solution was quickly poured into the base solution while stirring. The solution was observed to be cloudy, which finally cleared within one hour to obtain a clear solution. The reaction was allowed to continue for 2 hours, after which the solution was cooled 0-5°C to stop further nanocrystal growth. The solution thus prepared yielded 1 L of 0.04M ZnO colloidal solution.

[0089] Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap