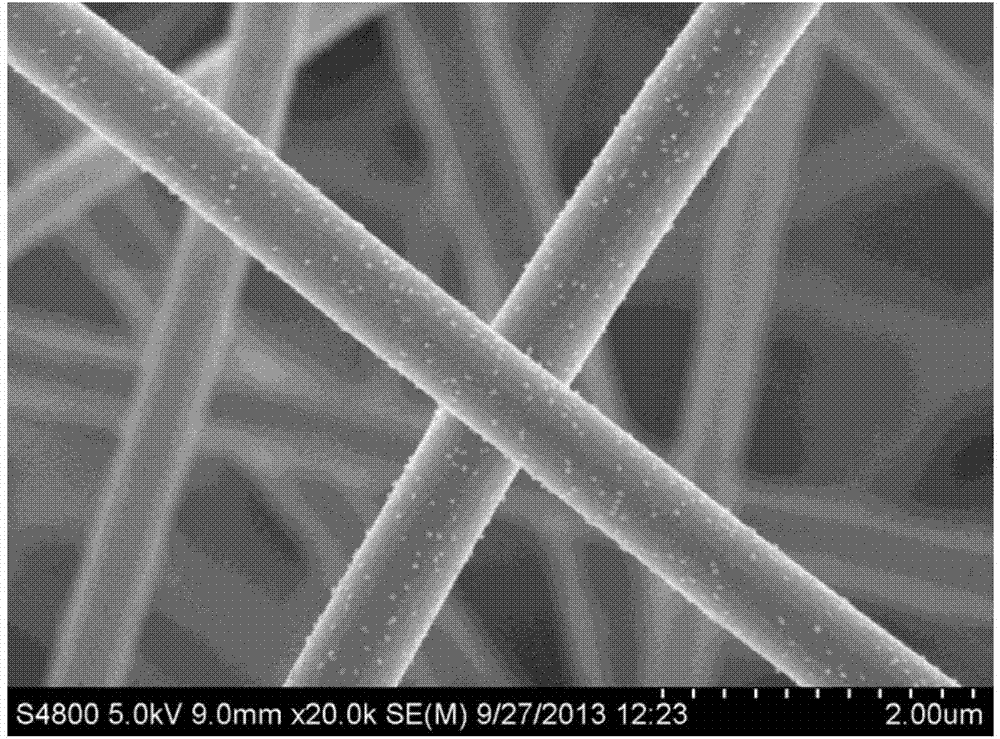

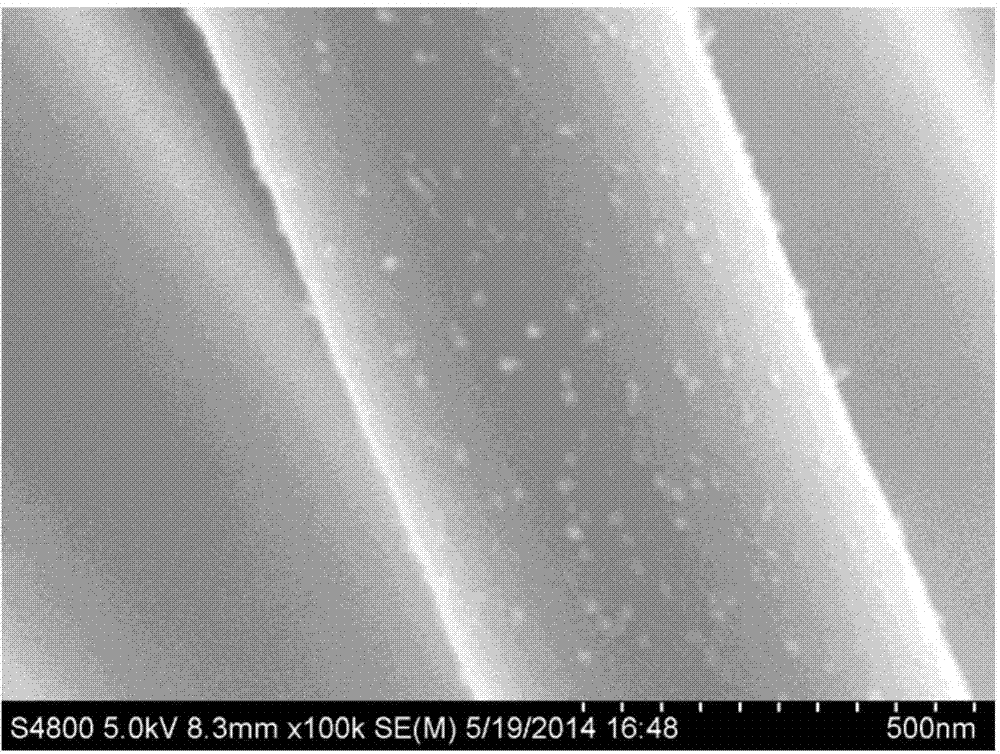

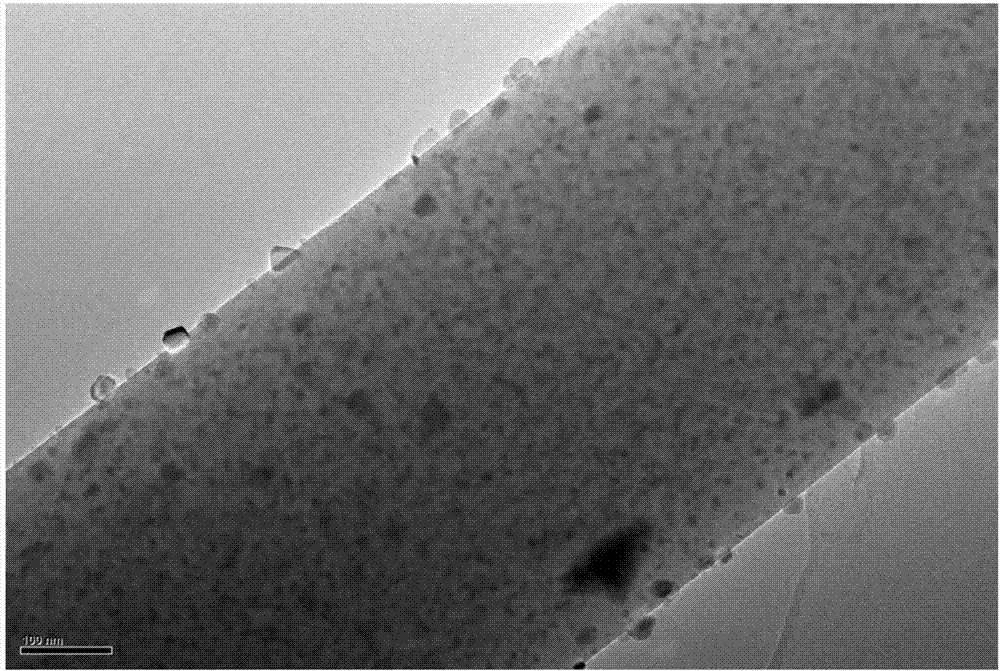

Preparation method of metal or metal oxide particle-containing CeO2 fiber catalyst

A technology of metal nanoparticles and oxides, which is applied in the field of preparation of CeO2 fiber catalysts, can solve the problems that have not been reported yet, and achieves the effect of simple and easy preparation method, low cost and broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Weigh 6.0g of cerium nitrate and 10.0g of deionized water and mix them, then magnetically stir for 12 hours to fully hydrolyze the cerium nitrate to obtain CeO 2sol solution; 5.0g polyvinylpyrrolidone (PVP) was dissolved in a mixed solvent of 5.0g dimethyl sulfoxide (DMSO) and 10.0g N,N-dimethylformamide (DMF), stirred on a magnetic stirrer 12h, to form a uniform transparent solution; then 0.3g catalyst palladium chloride (PdCl 2 ) dispersed in 3.0g DMF and ultrasonically treated for 4h to form a uniform and stable solution; finally, these three solutions were mixed and stirred for 0.5h to a uniform liquid, which is the spinning precursor used for electrospinning;

[0036] 2. Inject the electrospinning precursor solution prepared in 1 into the electrospinning device, and prepare a PdCl-loaded 2 CeO 2 / High polymer composite precursor fiber;

[0037] 3. Put the composite precursor fiber prepared in 2 in a crucible and place it in a muffle furnace, heat up to 800°C...

Embodiment 2

[0040] 1. Weigh 6.0g of cerium nitrate and dissolve it in 5.0g of deionized water and 5.0g of ethanol mixed solvent, then stir magnetically for 12 hours to fully hydrolyze the cerium nitrate to obtain CeO 2 sol solution; 50g polyvinylpyrrolidone (PVP) was dissolved in a mixed solvent of 5.0g dimethyl sulfoxide (DMSO) and 10.0g N,N-dimethylformamide (DMF), and stirred on a magnetic stirrer for 12h , to form a homogeneous and transparent solution; then 0.3 g of catalyst palladium chloride (PdCl 2 ) dispersed in 3.0g DMF and ultrasonically treated for 3h to form a uniform and stable solution; finally, these three solutions were mixed and stirred for 0.5h to a uniform liquid, which is the spinning precursor used for electrospinning;

[0041] 2. Inject the electrospinning precursor solution prepared in 1 into the electrospinning device, and prepare a PdCl-loaded 2 CeO 2 / High polymer composite precursor fiber;

[0042] 3. Put the composite precursor fiber prepared in 2 in a cru...

Embodiment 3

[0046] 1. Weigh 6.0g of cerium nitrate and dissolve it in 10.0g of ethanol, then magnetically stir for 12 hours to fully hydrolyze the cerium nitrate to obtain CeO 2 sol solution; 5.0g polyvinylpyrrolidone (PVP) was dissolved in 10.0g ethanol, stirred on a magnetic stirrer for 12h, to form a uniform and transparent solution; then 0.3g catalyst palladium chloride (PdCl 2 ) dispersed in 3.0g DMF and ultrasonically treated for 2h to form a uniform and stable solution; finally, these three solutions were mixed and stirred for 0.5h to a uniform liquid, which is the spinning precursor used for electrospinning;

[0047] 2. Inject the electrospinning precursor solution prepared in 1 into the electrospinning device, and prepare a PdCl-loaded 2 CeO 2 / High polymer composite precursor fiber;

[0048] 3. Put the composite precursor fiber prepared in 2 in a crucible and place it in a muffle furnace, heat up to 800°C for 4 hours in an air atmosphere at a rate of 10°C / min, and calcine for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com