Electronic parts packages and method for forming a cavity thereof

An electronic component and cavity technology, which is applied in the field of electronic component packaging and the cavity forming the electronic component package, can solve the problems of reduced degrees of freedom, difficulty in controlling azimuth angle and brightness, etc., and achieve simple control, simple azimuth angle and brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

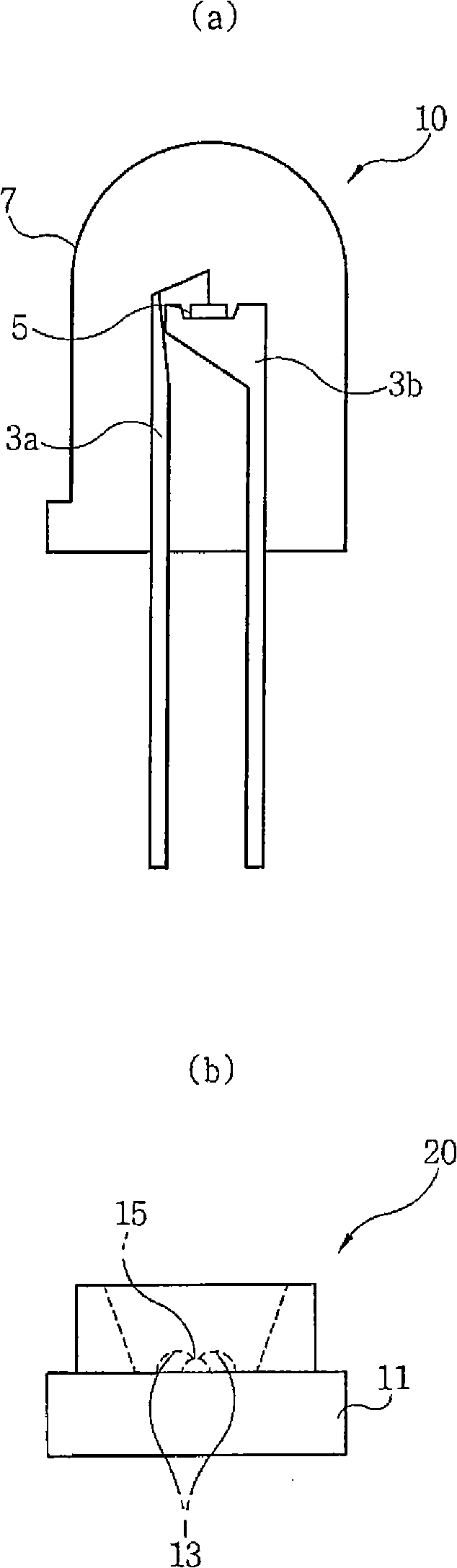

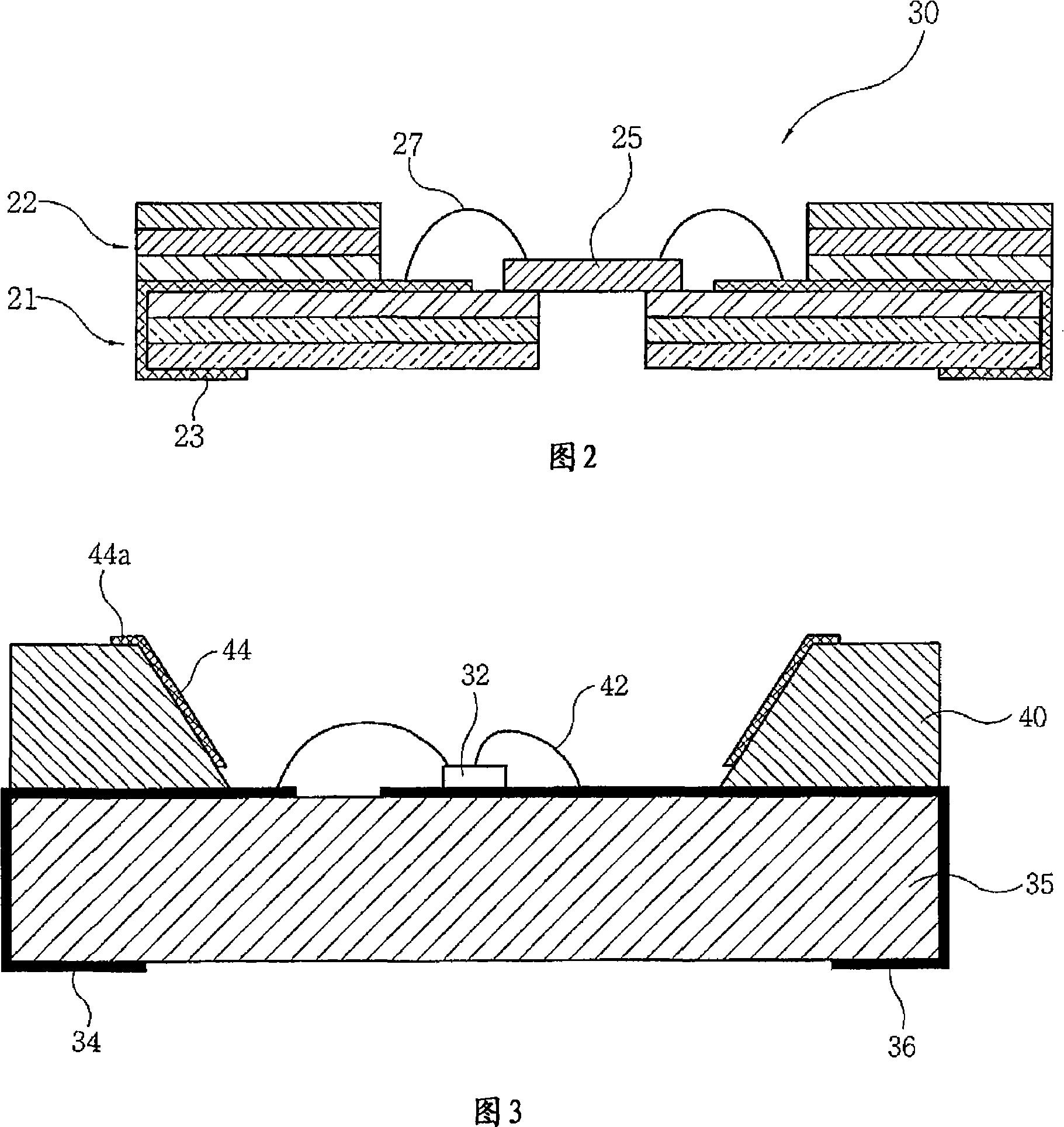

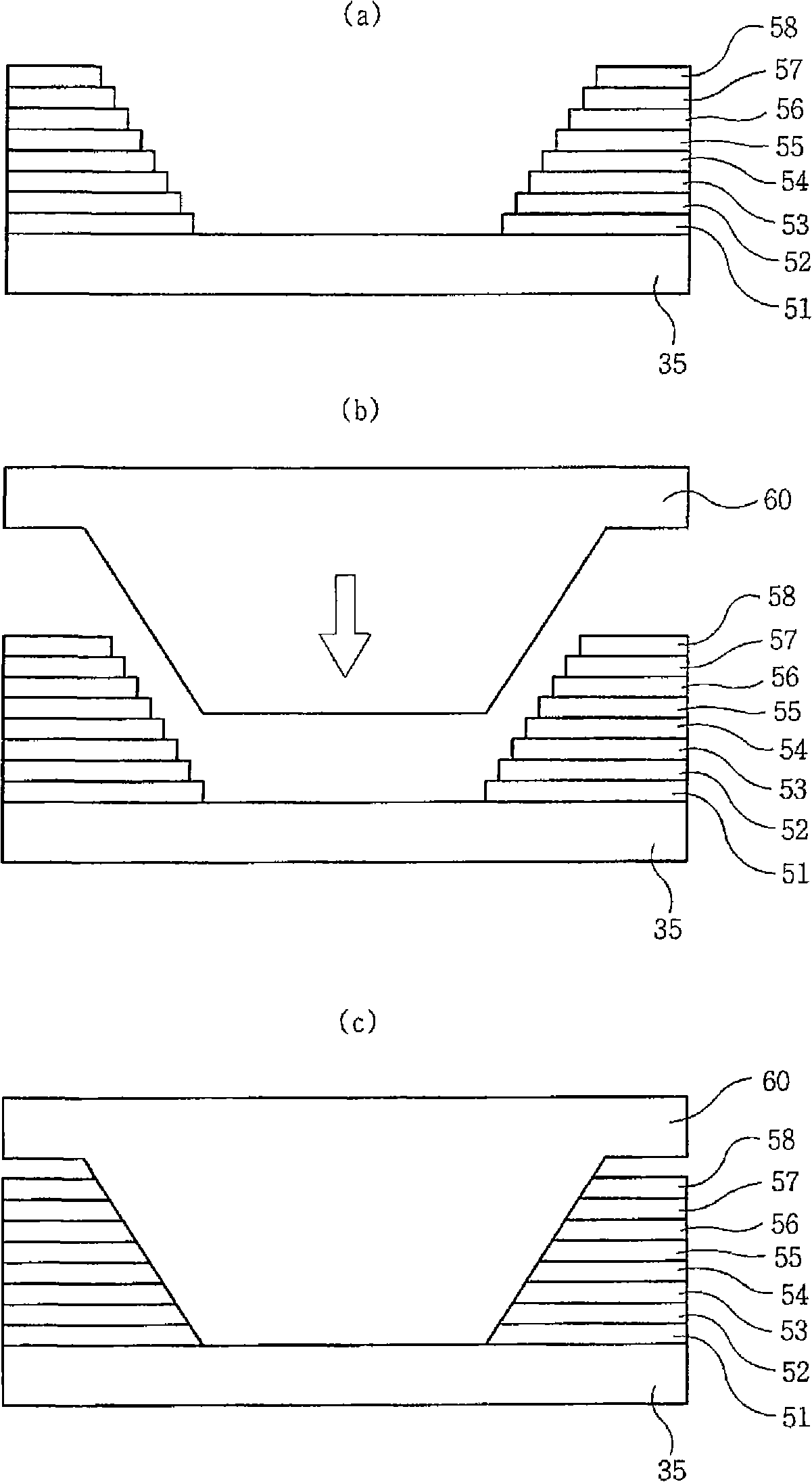

[0061] Hereinafter, an electronic component package according to the present invention and a method of forming a cavity of the electronic component package will be described with reference to the accompanying drawings. Hereinafter, a semiconductor package (ie, LED package) to which a light emitting diode is applied as an electronic component package will be described.

[0062] Figure 6 Is a cross-sectional view of the electronic component package according to the first embodiment of the present invention;

[0063] Figure 6 The LED package is configured with: a chip-type LED device 62; a lower ceramic substrate 60 on which the LED device 62 will be mounted; an upper ceramic substrate 70 arranged on the lower ceramic substrate 60, in the upper ceramic substrate 70, in the position A cavity having a predetermined shape is formed in an area corresponding to the area on which the LED device 62 will be mounted; pattern electrodes 64 and 66 formed on the lower ceramic substrate 60; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com