Tape cassette and tape printing system

A printing system and tape cassette technology, applied in printing devices, printing, typewriters, etc., can solve the problems of increased printing tape volume, larger tape cassette size, and soaring operating costs, so as to reduce operating costs and prevent erroneous transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

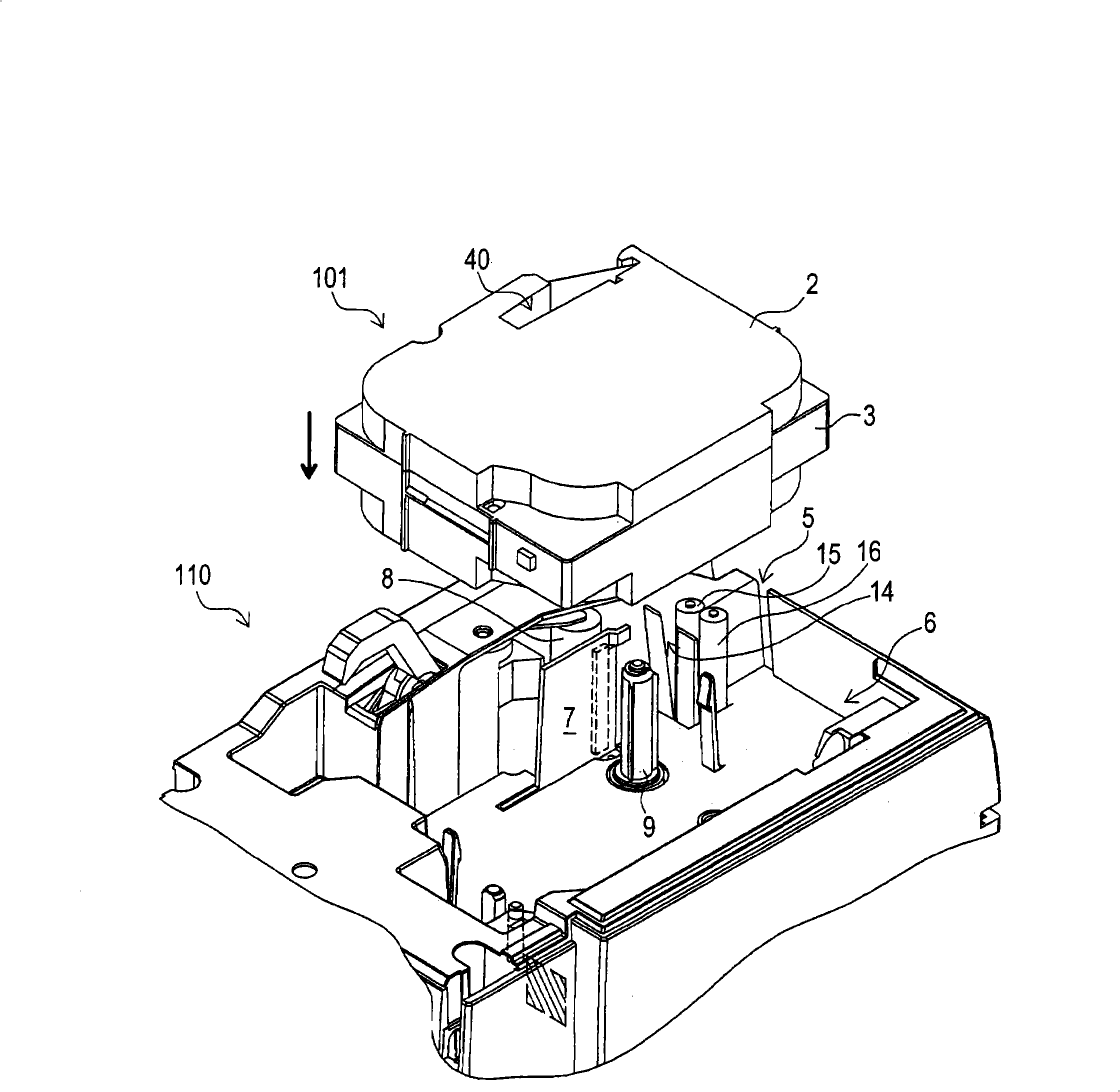

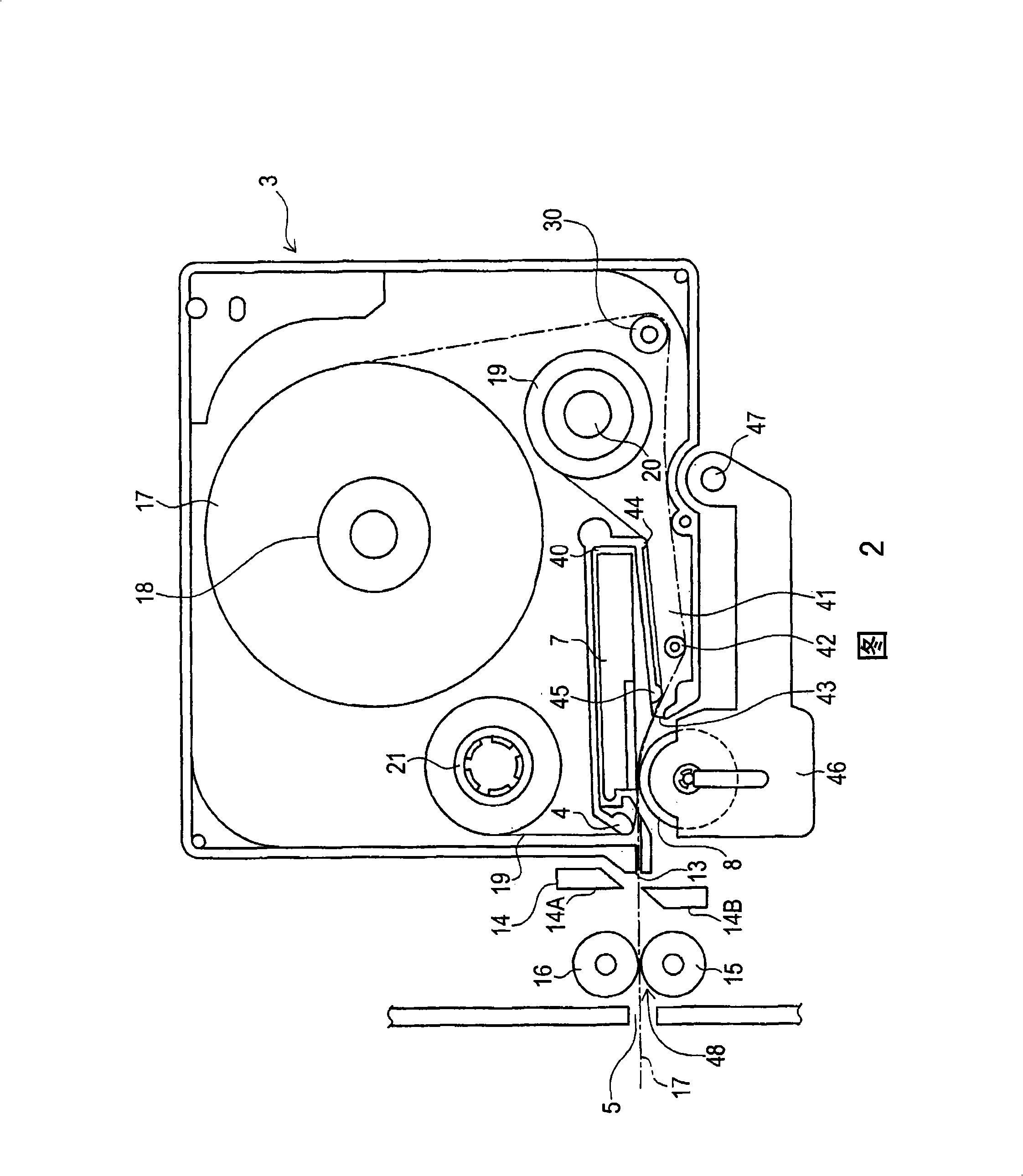

[0069] will now be based on figure 1 A description will be given of the tape cassette and the tape printing apparatus according to the first embodiment with reference to FIG. 2 . Here, the tape printing device includes a tape conveying device.

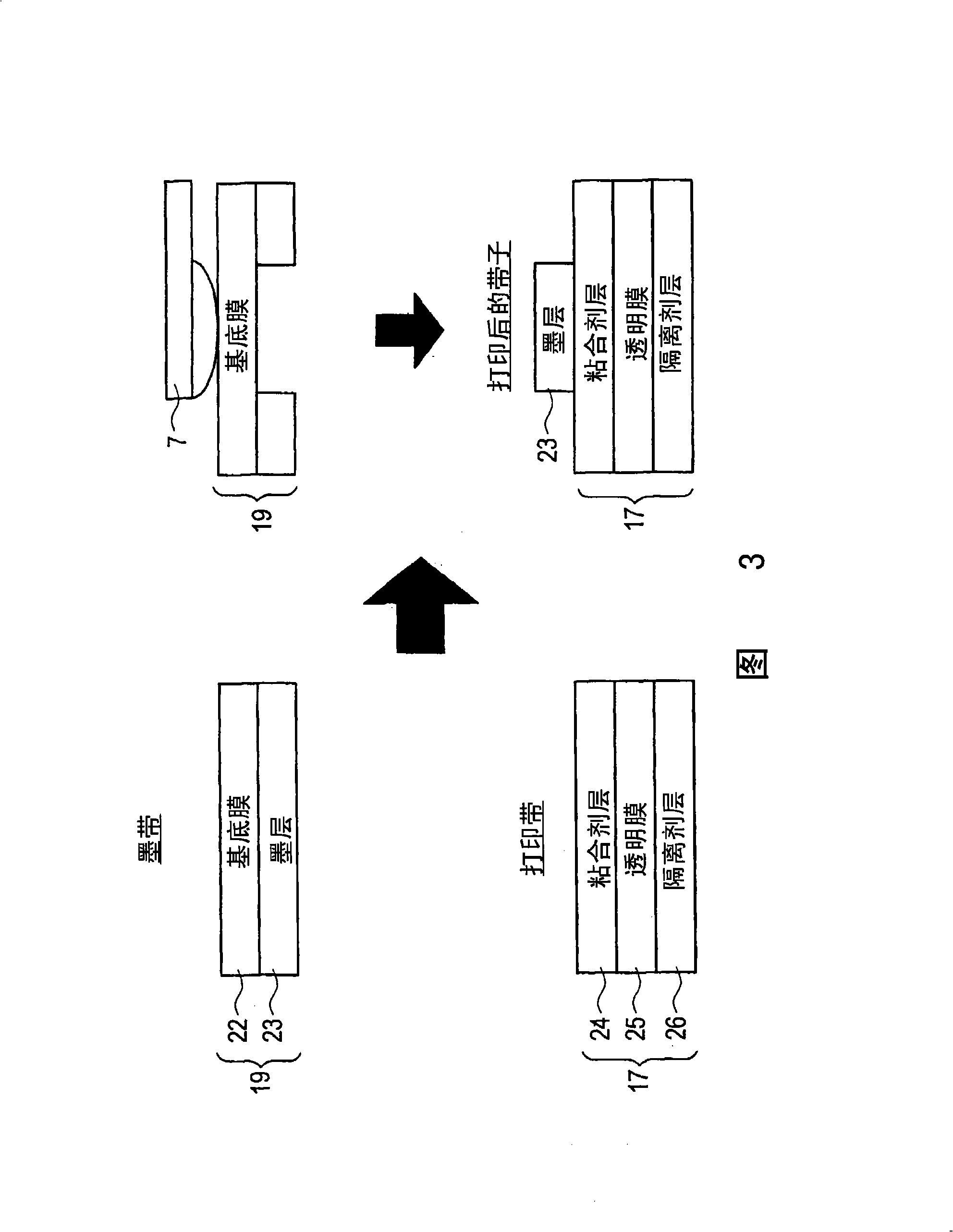

[0070] exist figure 1 In this case, the tape cassette 101 is detachably mounted on the cassette mounting portion 6 provided in the tape printing apparatus 110 . The tape cassette 101 has an upper case 2 and a lower case 3 . The upper case 2 serves as a cover member for covering the upper surface of the lower case 3 . The lower case 3 has a film tape reel 18 on which a film tape 17 is wound, and the film tape reel 18 is provided at a position slightly above a central portion thereof. The lower case 3 also has an ink ribbon reel 20 and an ink ribbon take-up reel 21 arranged at the lower right position of the film tape reel 18, the ink ribbon 19 is wound on the ink ribbon reel 20, and the ink ribbon take-up reel 21 takes the ink rib...

no. 2 example

[0099] Next, based on Figure 5 and 6 to describe the tape cassette and the tape printing apparatus according to the second embodiment. The configuration of the tape cassette 101 according to the second embodiment is the same as that of the tape cassette 101 according to the first embodiment. Also, the configuration of the tape printing apparatus 210 according to the second embodiment is basically the same as that of the tape printing apparatus 110 according to the first embodiment. In the following description, the same elements as those of the tape cassette 101 and the tape printing apparatus 110 according to the first embodiment are denoted by the same reference numerals.

[0100] In the tape printing device 110 according to the first embodiment, the tape conveying roller 16 is provided in the tape printing device 110 . However, in the second embodiment, the tape feed roller 77 has the same function as the tape feed roller 16 in the first embodiment, and the tape feed rol...

no. 3 example

[0123] In the above-mentioned second embodiment, when the film tape is conveyed after printing, the auxiliary paper medium is rewound on the auxiliary paper medium take-up reel. As a result, it is no longer necessary to peel off the secondary paper medium when adhering the printed film tape to the target body. However, the adhesive layer of the film tape is not protected at this time. This makes it difficult to store a film strip formed in the above manner for a long period of time when the film strip is not bonded to the target body.

[0124] The third embodiment to be described is made to solve these problems. will then be based on Figure 9 A tape cassette, sub-cassette, and tape printing apparatus according to a third embodiment will be described with FIG. 10 .

[0125] The configuration of the tape cassette 101 according to the third embodiment is the same as that of the tape cassette 101 according to the second embodiment.

[0126] Also, the configuration of the tape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com