Ring embedded type flexible automobile brake drum

A vehicle braking and flexible technology, applied in the direction of brake drums, etc., can solve the problems of high price, bursting, affecting the driving of vehicles, etc., to achieve broad market prospects, improve service life, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

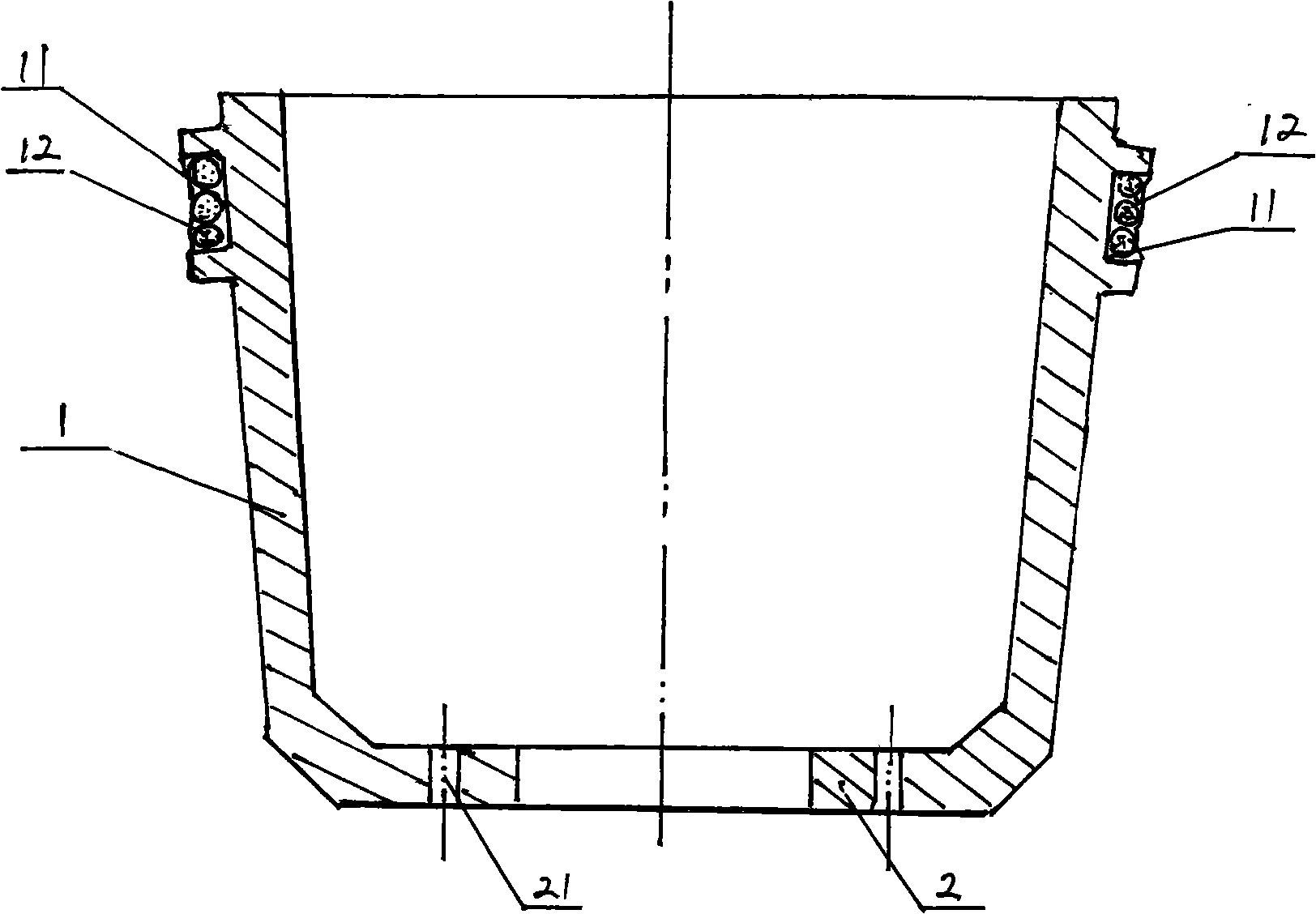

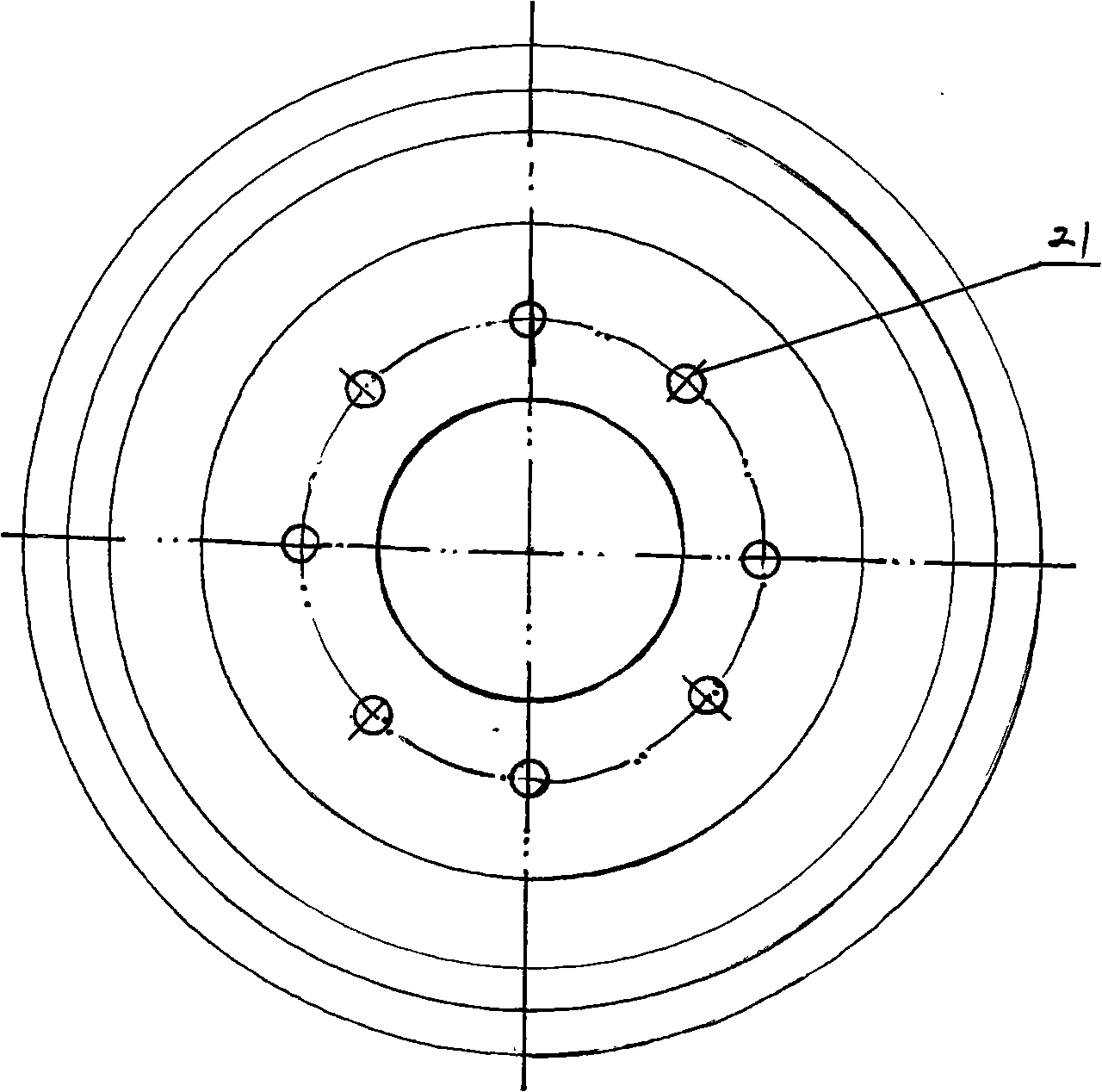

[0013] according to figure 1 In the structure shown, castings are used to manufacture the ring-embedded flexible automobile brake drum, wherein the drum body 1 adopts a conical structure, and the groove 11 adopts a cylindrical or conical outer wall structure of the drum body. Grooves 11 are nested with hoops 12 composed of three parallel steel wire ropes. The ring-shaped connection interface of each steel wire rope is fixedly connected by welding, and the hoops 12 are fixedly connected with the drum body 1 by welding. The overall plane of the hoop cable 12 after welding should not be higher than the outer circle plane of the groove 11, and the extra parts need to be polished flat with a grinder, so that the use of the automobile brake drum will not be affected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com