Yarn clamping device for underwinding yarns on spindles of a ring spinning or ring twisting machine

A technology of ring spinning machine and clamping device, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problems of unsatisfactory and satisfactory safety, and achieve The effect of reliable removal

Inactive Publication Date: 2010-12-01

京特·柯尼希

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This design is unsatisfactory because the yarn wound on the bottom of the tube can only be inserted into the wedge-shaped clamping slit that closes at low speed

Moreover, the exact control of the delivery speed at this stage does not allow for satisfactory safety during clamping during bobbin change

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

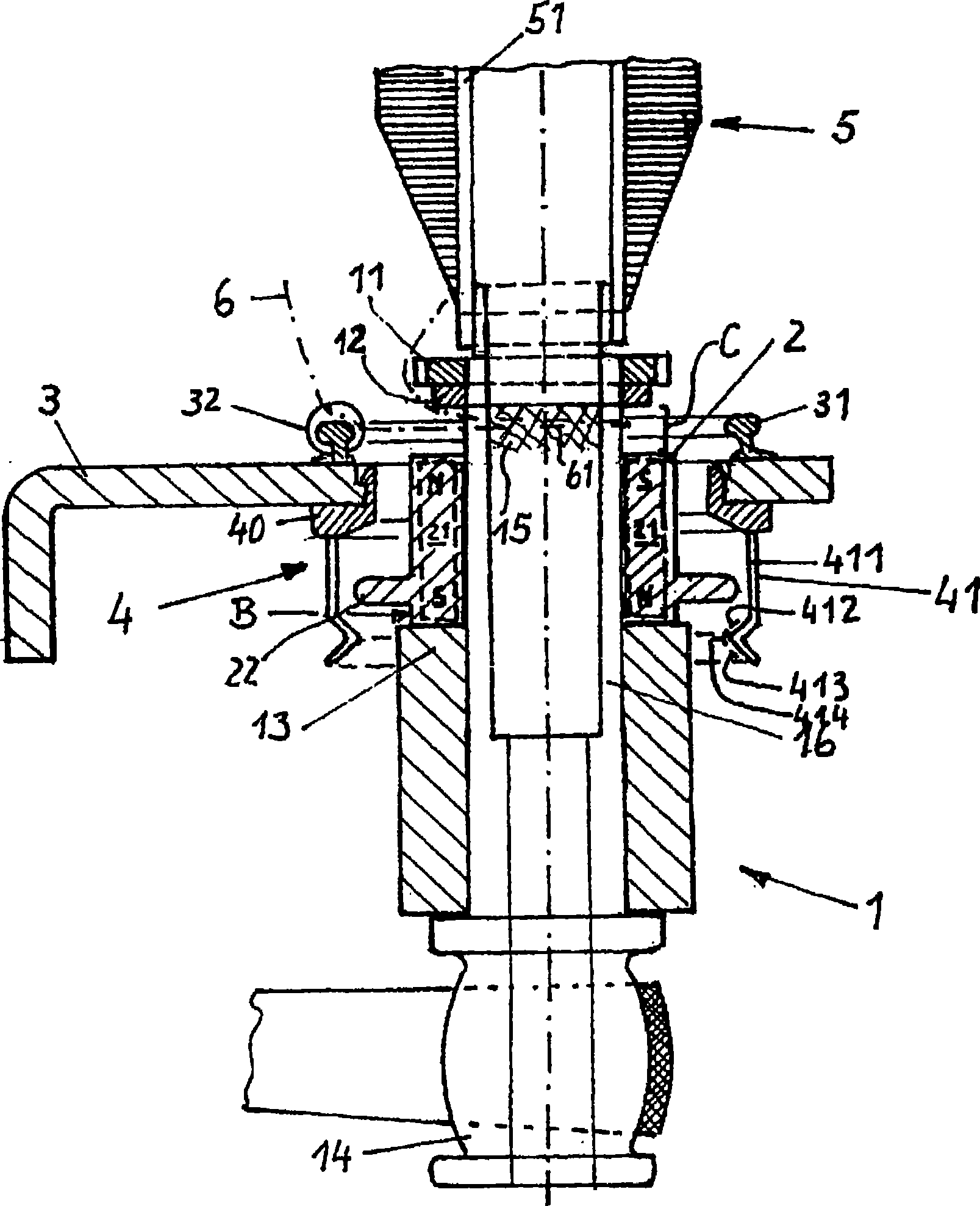

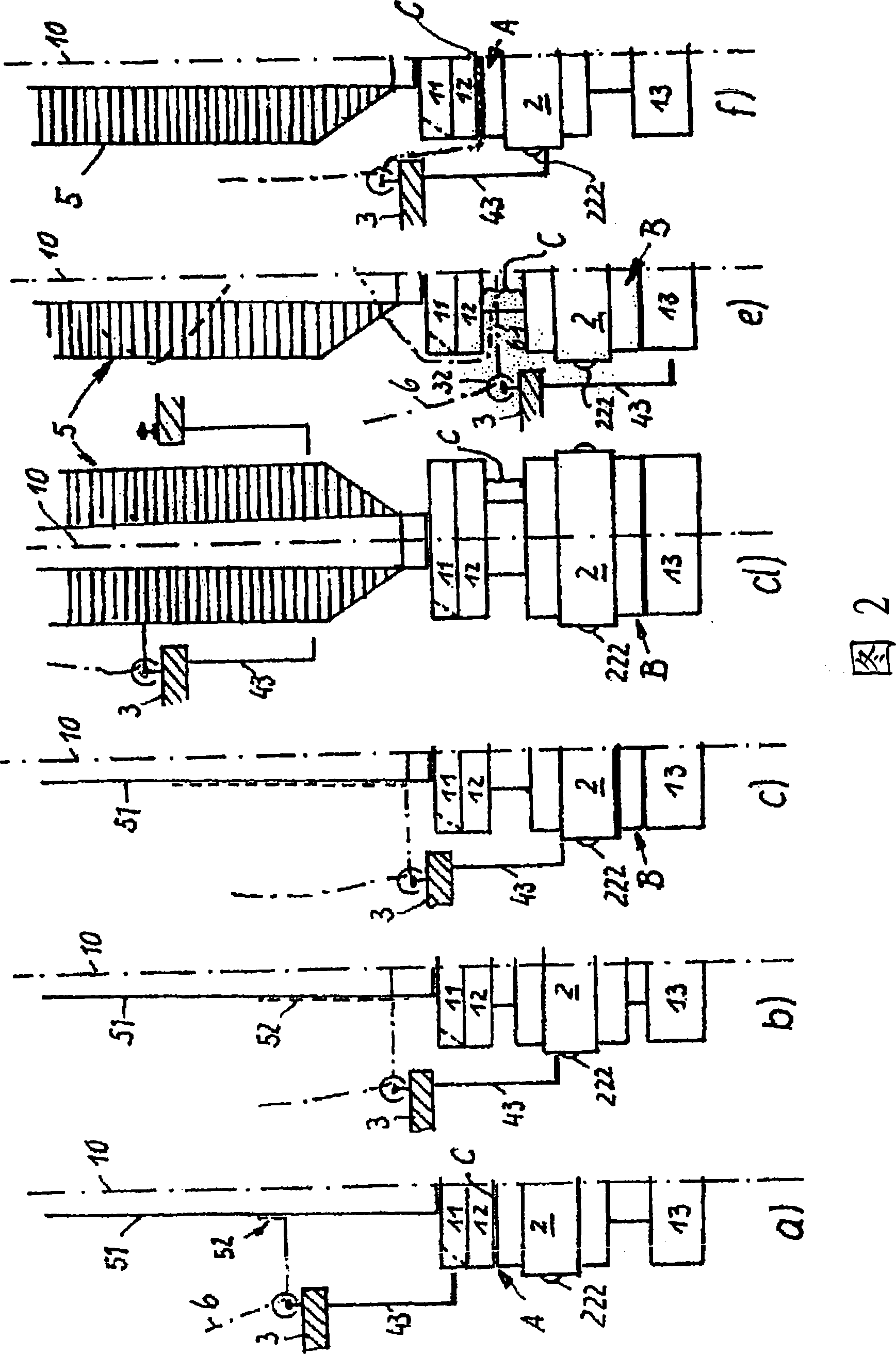

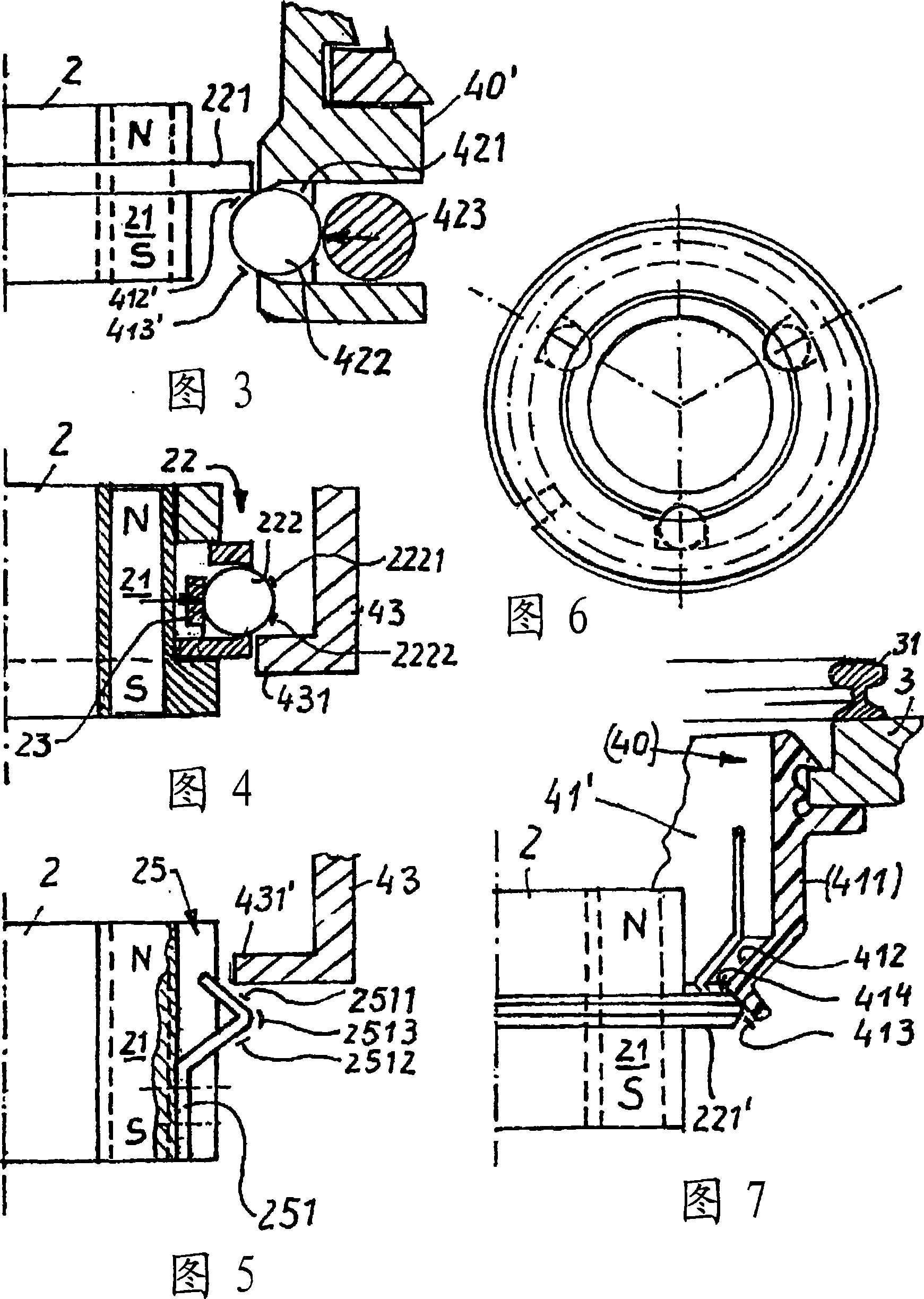

The invention relates to a thread clamping device for lower winding threads on spindles (1) of a ring spinning frame or ring twisting frame. A clamping sleeve (2) is provided between a clamping ring (12) and a radially protruding flange (13) on the spindle which can be axially displaced between a clamping position (A), which is defined by the position on the clamping ring (12), and an open position (B). The clamping sleeve (2) is associated with an actuation device (4) for the axial displacement thereof, which co-operates with radially extending means on the clamping sleeve (2). The clamping sleeves (2) are associated with elements (21; 17) for fixing the position thereof at least in the clamping position (A). The aim of the invention is to introduce lower windings into the clamping gap and to improve the removal thereof from the clamping gap.; As a result, the actuation elements (41) and / or the radially protruding means (22) are maintained on the clamping sleeve (2) in a radially, elastically touching manner in relation to each spindle axis (10) and are provided (C) with rising sloping surfaces (412, 413) which are radially effective in both relative directions of movement.

Description

Yarn clamping device for underwinding yarn on the spindles of ring spinning machines or ring twisting machines technical field The invention relates to a yarn clamping device for underwinding a yarn on a spindle of a ring spinning machine or a ring twisting machine, wherein an underwinding crown is arranged on the spindle a clamping ring and a radially projecting collar at a distance below the clamping ring; wherein on the spindle an axially movable clamping sleeve is positioned between the clamping ring and the collar; Wherein the clamping sleeve is movable by an actuating device between a clamping position defined by abutting against the clamping ring and an open position defined by abutting against the collar to open or close a clamp and wherein the clamping sleeve is equipped with: radially extending parts for operating a plurality of actuating elements of the actuating device; and for fixing the position of the clamping sleeve in at least the closed position multiple el...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): D01H1/38

CPCD01H1/38

Inventor 京特·柯尼希

Owner 京特·柯尼希

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap