Real-time tracking control method of magnetron arc sensing weld seam in gas metal shielded welding

A melting electrode gas and arc sensing technology, used in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor real-time performance, complex structure, low control accuracy, etc., and achieve good tracking effect and high control accuracy. , The effect of stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

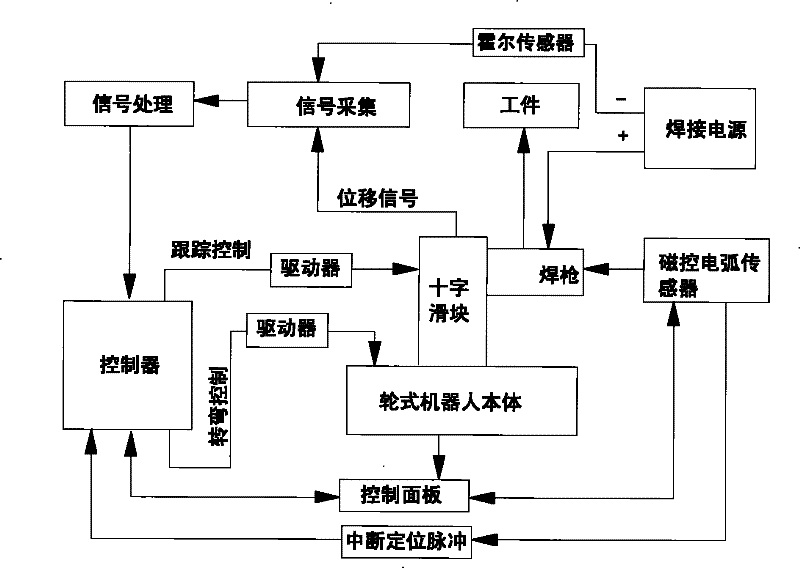

[0014] In Embodiment 1, the present invention is composed of a welding system, a control system, and a tracking actuator composed of a magnetron arc sensor, a welding gun, and a welding power source. The magnetron arc sensor is installed on the welding gun, and the welding gun is installed on the tracking actuator. The magnetron arc sensor generates an alternating magnetic field and drives the MIG welding arc to swing at a certain frequency and amplitude, thereby scanning the weld to obtain weld information, which is filtered and amplified by the filter circuit and sent to the control system for processing and control The system adjusts the execution structure of the slider and the welding trolley in real time to track the weld seam. The welding point of the system is the collection point of deviation signal, and it can be tracked while welding, and the real-time performance is very good. See figure 1 .

[0015] It mainly solves the problems of complicated structure, high cost,...

Embodiment 2

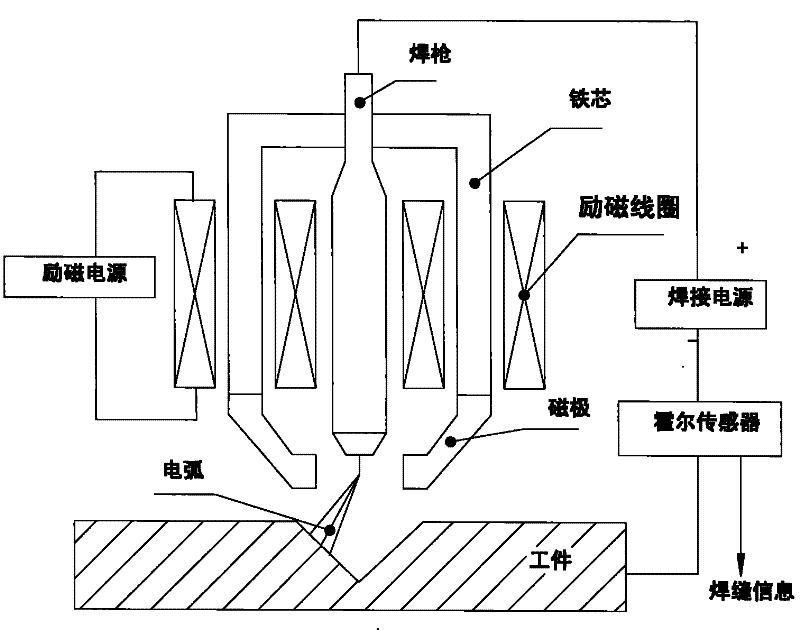

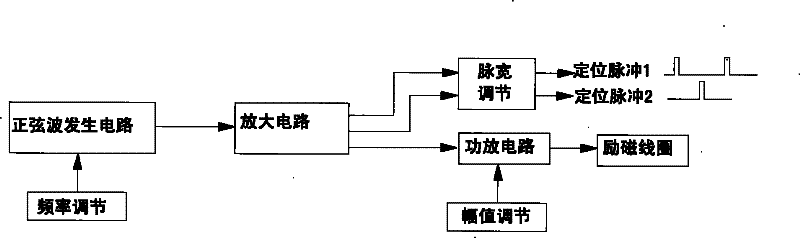

[0017] In Embodiment 2, the magnetron arc sensor of the present invention is composed of excitation power supply, magnetic field generating device, Hall sensor and other components. The magnetic field generating device is directly installed on the welding gun of MIG welding, so the temperature is very high during welding. , There are a lot of spatters. The pair of magnetic poles of the magnetic field generator are made of high temperature resistant materials and made into a replaceable form. The structure of the magnetron arc magnetic field generator figure 2 . The function of the excitation power supply is to generate an excitation current with adjustable frequency and amplitude and two interrupt pulse signals with the same frequency as the excitation current. The function of the interrupt pulse signal is to determine the position of the start of sampling. Refer to the structure diagram of the excitation power supply. image 3 . During welding, the excitation coil generates a...

Embodiment 3

[0018] In Embodiment 3, the filter circuit of the present invention uses two Butterworth low-pass filters connected in series for hardware filtering. Because in MIG welding, the arc length is short, the spatter is large, and there are many interference factors, so the processing of the sampled signal is very important, so the hardware such as Figure 4 2 Butterworth low-pass filters connected in series for hardware filtering. See Figure 4 , The rest is the same as the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com