Reparing method of polyethylene twist netting for net box or purse net

A mesh and ethylene technology, which is used in the field of knotless mesh repair for fishing, can solve the problems of no cage or seine, no repairing technology and repairing method, etc., so as to reduce the incidence rate, maintain the quality and mechanical properties. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

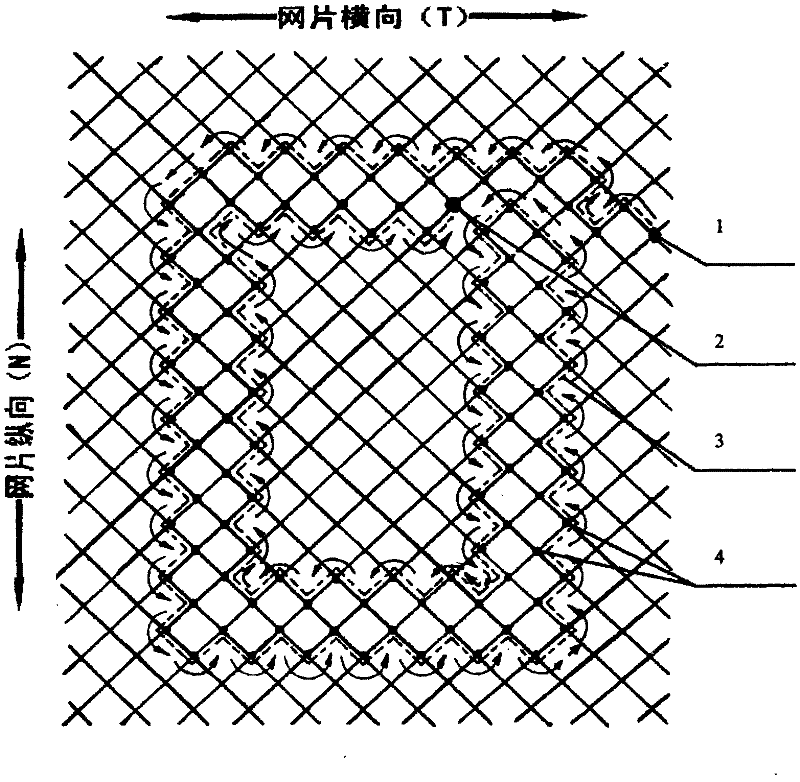

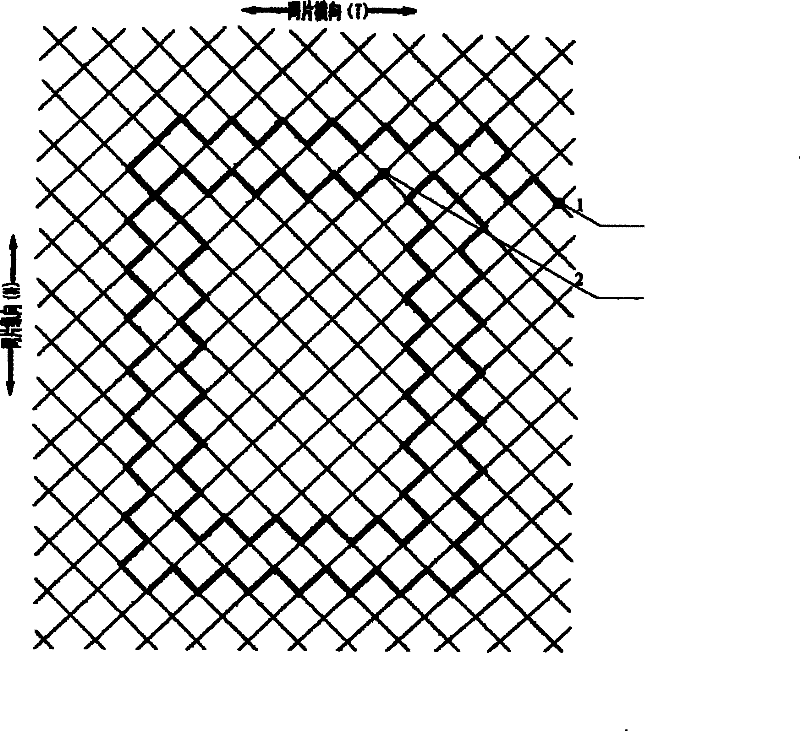

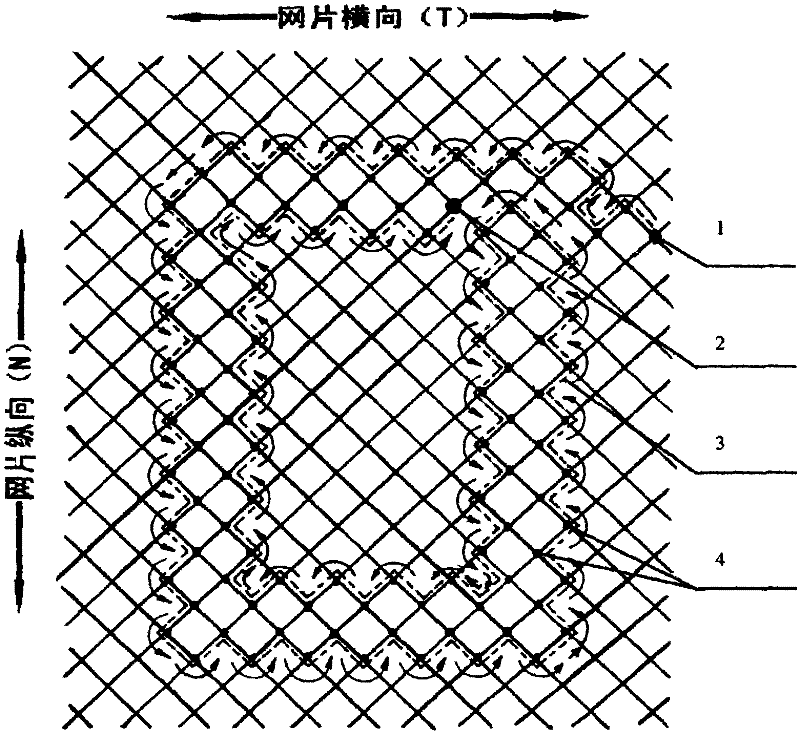

[0009] The invention includes the trimming of holes in the polyethylene twisted mesh used for cages or purse seines and the treatment of the ends of the trimming edges and feet, the selection and cutting of the mesh for mending, the selection of sutures for mending and the end of the sutures. Treatment and repair form of polyethylene twisted mesh, this method trims the irregular shaped hole of polyethylene twisted mesh into a rectangular or square hole by direct cutting method, and uses the melting method to process the cutting around the rectangular or square hole The end of the mesh foot of the cutting edge is to prevent the end of the mesh foot of the cutting edge from loosening under the action of water or small external force in the future; choose a new mesh of the same specification and trim it into a rectangle or square by direct cutting method. After trimming, the rectangle or The end of the mesh foot of the cutting edge of the square mesh should be treated by melting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com